Double-electrolytic tank for simulating under-deposit corrosion and application

A technology of under-deposit corrosion and electrolytic cell, which is applied to the dual electrolytic cell and application field of simulating under-deposit corrosion, can solve the problems of difficult to obtain electrochemical information, does not consider the influence of scale layer, and does not consider the relationship between occluded batteries, etc., and achieves feasibility Strong, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

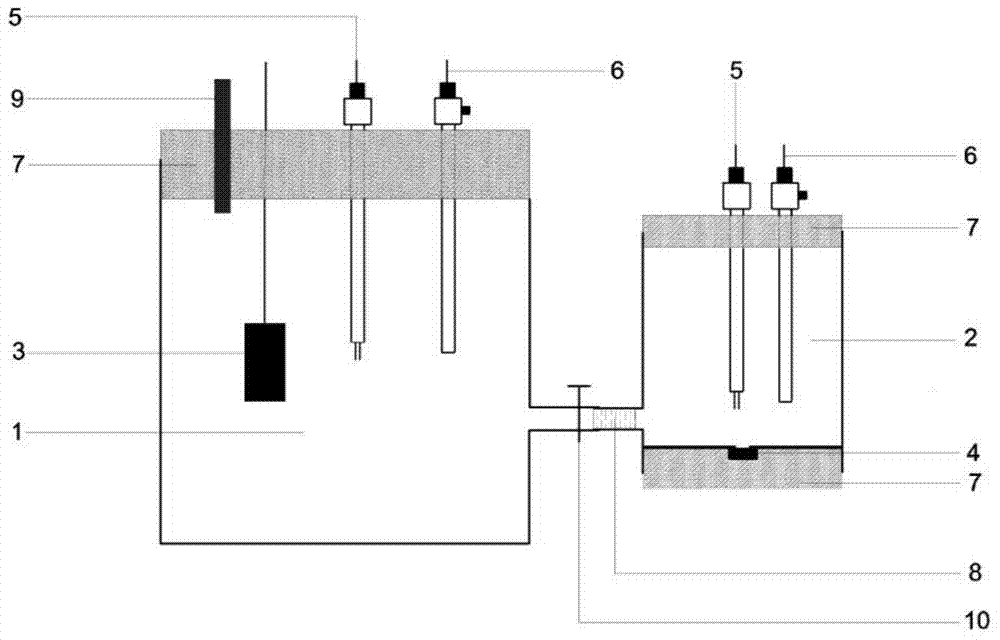

[0013] Couple the occluded working anode with the body cathode, and use the corrosion electrochemical test system to test the coupling current inside and outside the occluded area.

Embodiment 2

[0015] A corrosion electrochemical test system is used to regularly measure the anode potential of the occluded area and the body cathode potential.

Embodiment 3

[0017] After the occluded working anode and the body cathode are coupled for different times, the occluded anode and the body cathode are respectively linearly polarized, and the corresponding polarization resistance is tested by the corrosion electrochemical test system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com