Polarized light irradiating device

An illumination device and polarized light technology, applied in optics, optical elements, nonlinear optics, etc., to achieve the effects of uniform polarization orientation, high polarization extinction ratio, and wide irradiation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

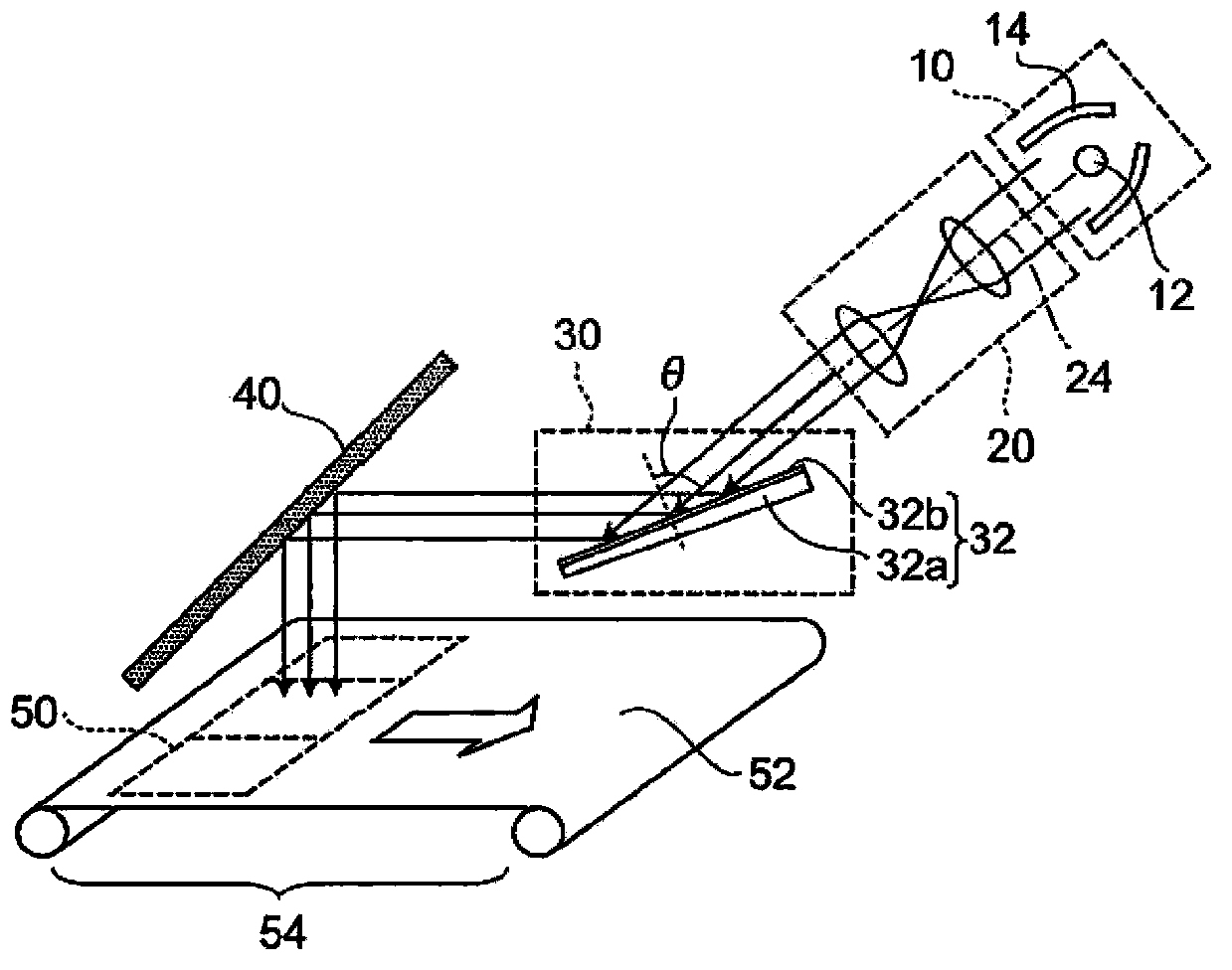

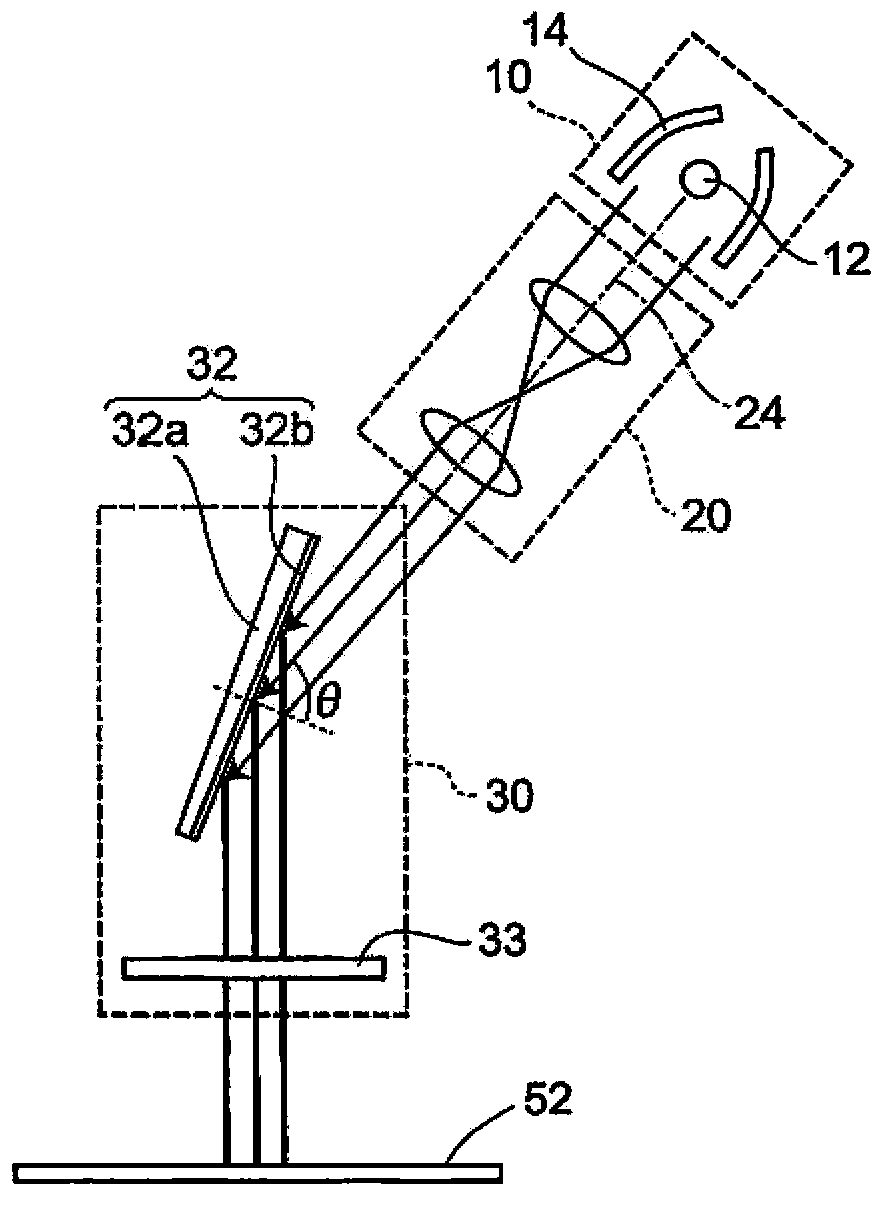

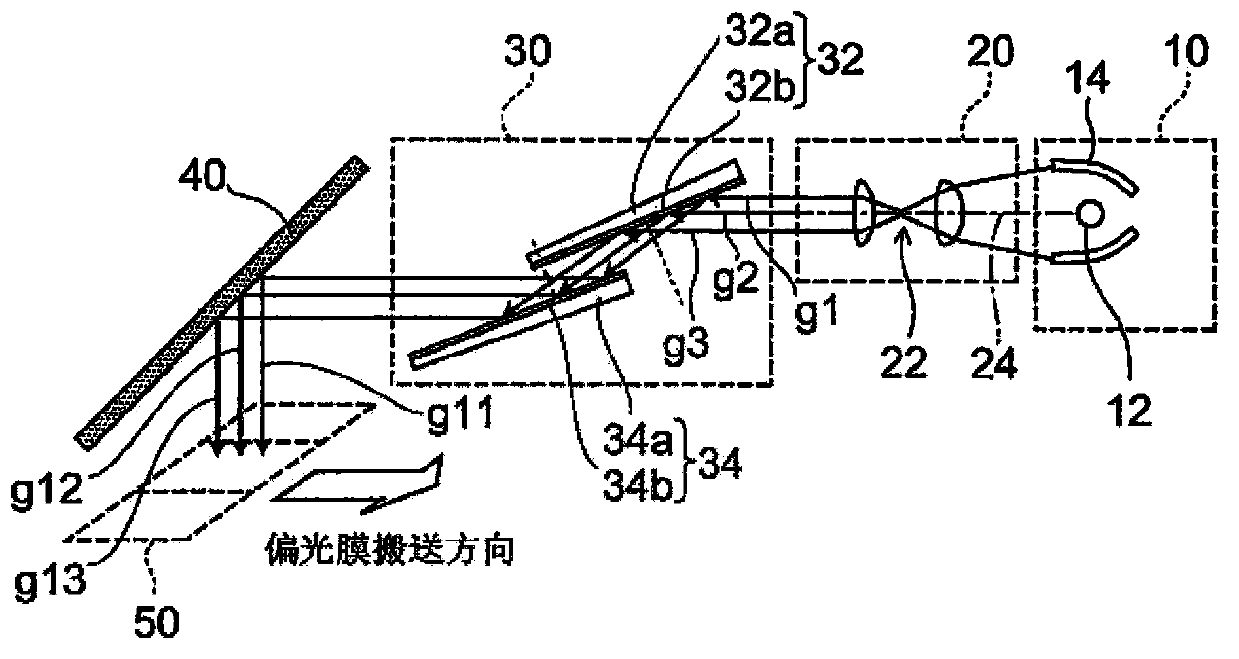

[0073] Below, refer to the attached Figure 1 Embodiments of the present invention will be described.

[0074] figure 1 It is a configuration diagram of the polarized light irradiation device according to the first embodiment of the present invention.

[0075] The polarized light irradiation device includes a light source unit 10 , a parallel light forming unit 20 and a polarized light forming unit 30 . The light source unit 10 includes an ultraviolet lamp 12, a condenser lens 14, and the like. The polarized light forming unit 30 includes a plate-type polarizing beam splitter 32 , splits the ultraviolet light emitted from the parallel light forming unit 20 into a p-polarized light component and an s-polarized light component, and emits the s-polarized light component as an irradiation beam. In addition, in the specification, "ultraviolet light" means light having a wavelength of 390 nm or less, and includes deep ultraviolet light.

[0076] The parallel light forming part 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com