Industrial frequency transformer

A power frequency transformer and transformer technology, applied in the field of transformers, can solve problems such as increasing equipment maintenance costs, and achieve the effects of being easy to popularize and use, novel and reasonable in design, and easy to install.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

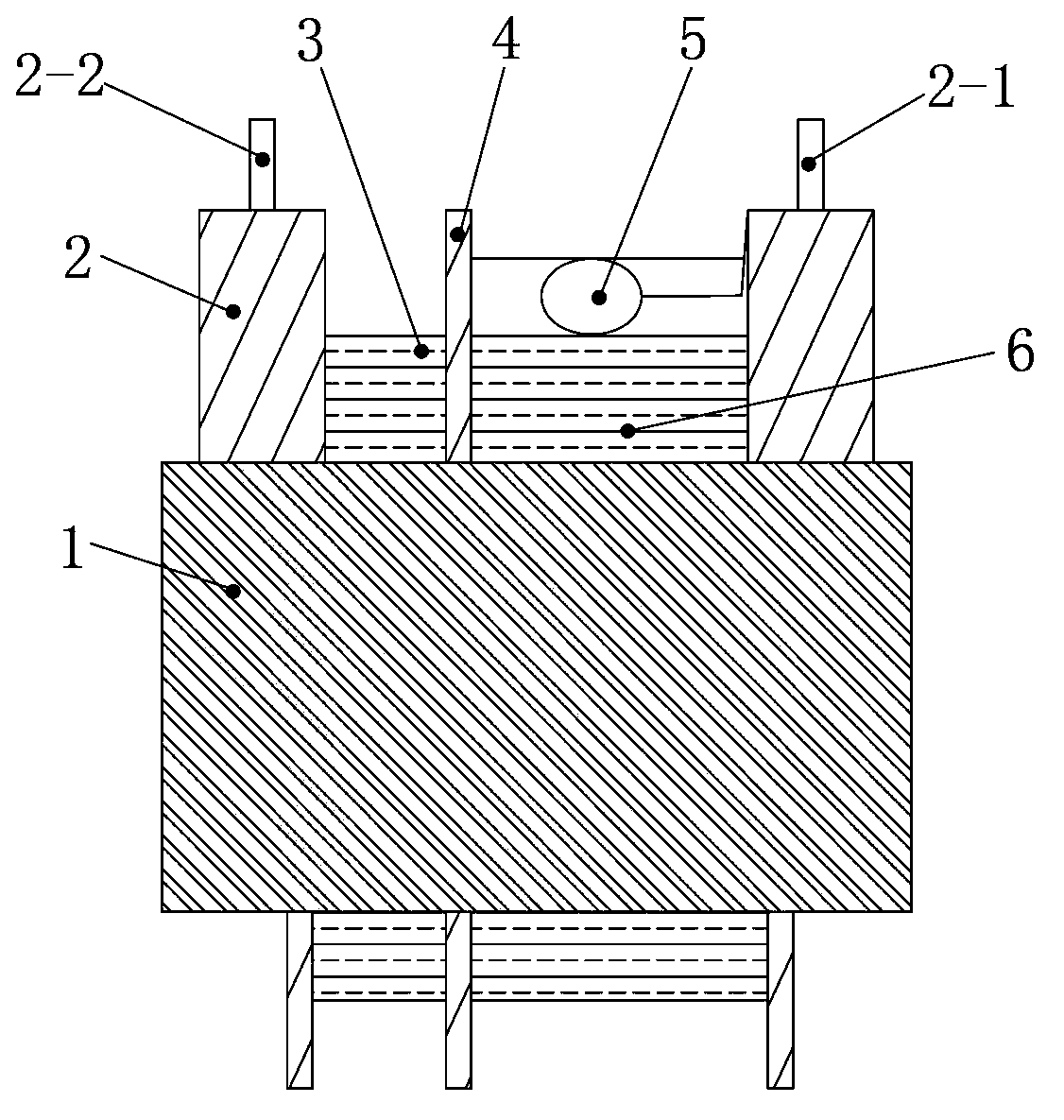

[0018] Such as figure 1 A power frequency transformer shown includes a transformer winding bobbin 2, a primary coil 6 and a secondary coil 3 are wound in the skeleton groove of the transformer winding bobbin 2, and the primary coil 6 and the secondary coil 3 are both Made of copper wire, the transformer winding frame 2 is provided with an isolation rib 4 for separating the primary coil 6 and the secondary coil 3, the isolation rib 4 is a frame structure, and the primary coil 6 is located on the isolation rib 4 The right side of the secondary coil 3 is located on the left side of the isolation rib 4, and the distance between the isolation rib 4 and the left end face of the transformer winding frame 2 is smaller than the distance between the isolation rib 4 and the right end face of the transformer winding frame 2 distance, the primary coil 6 is connected to the lead-out end 2-1 on the transformer winding frame 2, the secondary coil 3 is connected to the lead-out end 2-2 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com