Apparatus for generating sodium hypochlorite

A technology of sodium hypochlorite and generating device, which is applied in water/sludge/sewage treatment, cells, electrolysis process, etc., can solve the problems of by-product-chlorate, high cost, maintenance and management cost, large scale of equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0056] The stated purpose of the present invention and its structural and functional characteristics will be described according to the preferred embodiments of the accompanying drawings.

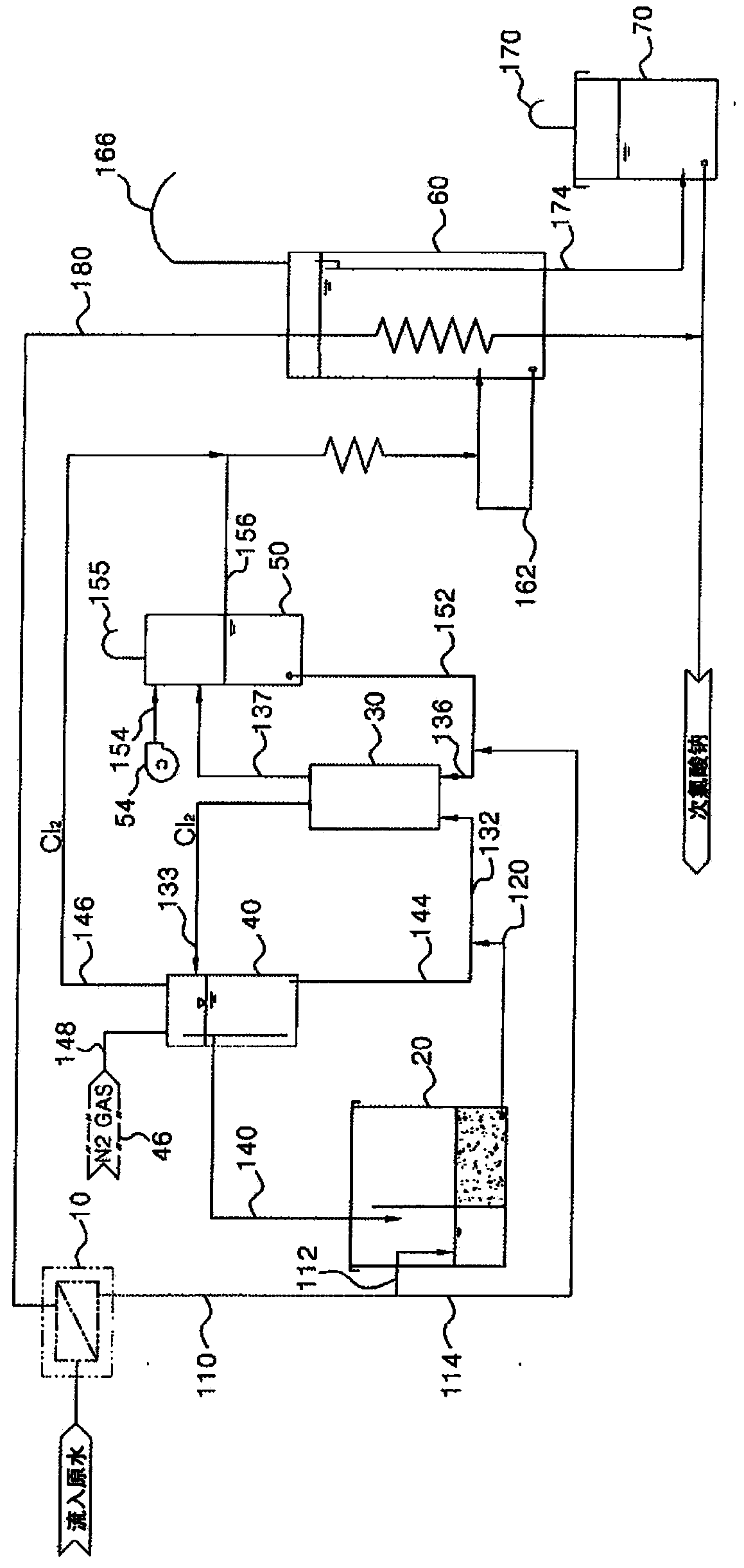

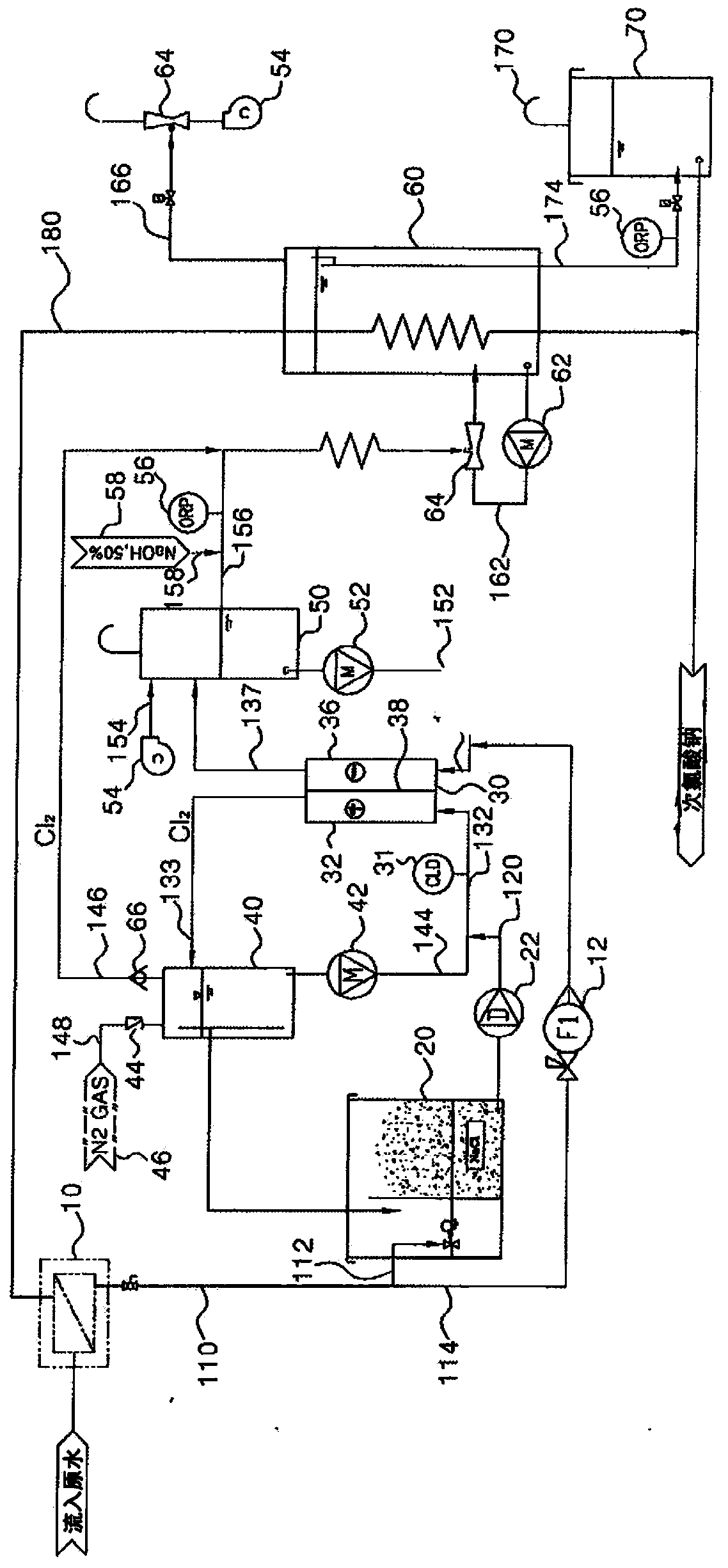

[0057] For the basis figure 1 The detailed description of the reaction sequence of the formed sodium hypochlorite generator implementation example is as follows:

[0058] First, the raw water passes through the pretreatment method (10) to produce pure water that has filtered out impurities such as calcium or magnesium, and the generated pure water passes through the first pure water inflow line branched from the pure water inflow line (110) ( 112) It flows into the salt storage tank (20), meets the sodium chloride kept in the salt storage tank (20), and forms a saturated sodium chloride aqueous solution.

[0059] The saturated aqueous sodium chloride soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com