Wastewater treatment using natural solid additives in activated sludge process

A wastewater treatment and activated sludge technology, applied in water/sludge/sewage treatment, biological sludge treatment, biological water/sewage treatment, etc., can solve the problems of low absorption capacity and achieve low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

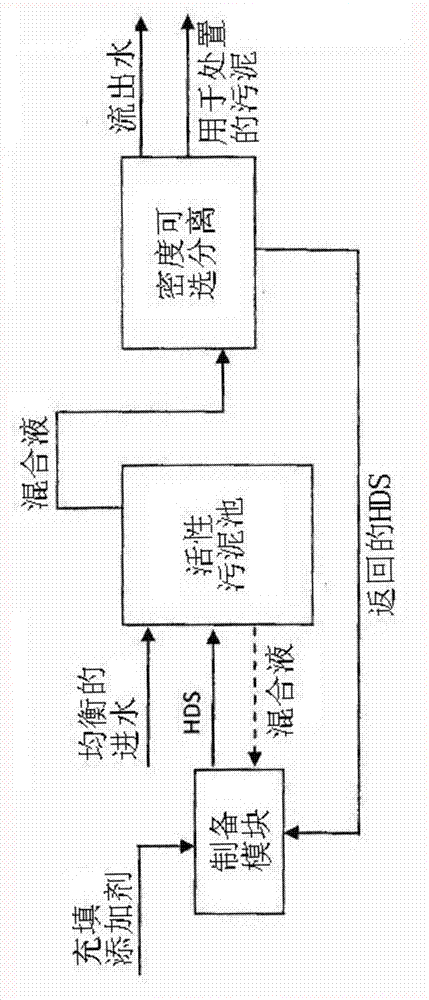

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

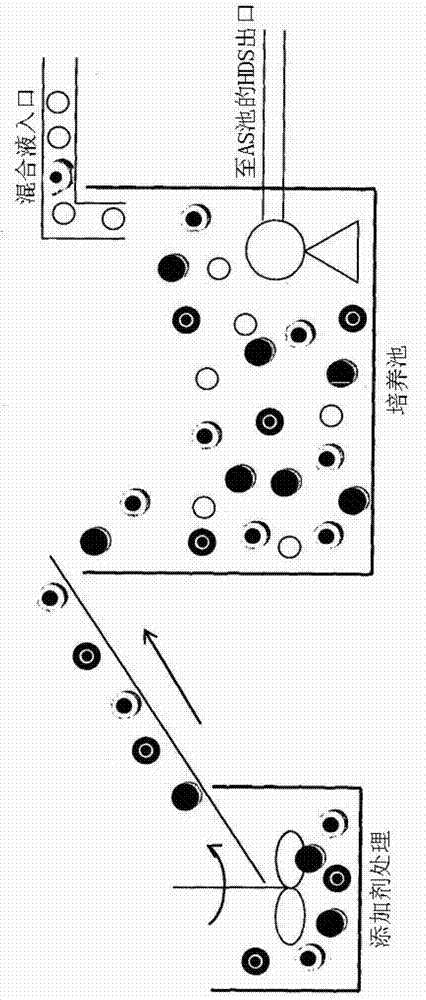

[0080] Example 1: Cultivation of sludge with additives: culture vessel

[0081] Figure 5 A culture vessel with a volume of 20 liters is shown. An inlet and an outlet for the mixed liquor are added in the upper part of the container. Add an outlet for high-density sludge (HDS) for cultivation near the bottom of the vessel. A dispenser with a height of two-thirds to three-quarters of the height of the container is located vertically in the center of the container, wherein said dispenser is not fully submerged in water. The distributor ensures that the inlet and outlet for the mixed liquor are not in the same compartment so that the mixed liquor lasts a long residence time in the container before flowing out through the outlet. An air diffuser is installed at the bottom of the container, which is connected with a blower.

Embodiment 2

[0082] Example 2: Cultivation of High Density Sludge with Additives: Cultivation Process

[0083] The culture vessel described in Example 1 was filled with mixed liquor from the activated sludge (AS) tank of the wastewater treatment plant for inoculation. The settled sludge volume was measured to be 300-400ml / L. 1 kg of the additive was added to the container after wetting it with water. The vessel was vented to maintain dissolved oxygen (DO) levels at 3 mg / L. After one week, repeat the following steps every 6 hours:

[0084] 1) Stop the ventilation and close the mixture inlet;

[0085] 2) After 30 minutes, replace the 12L upper mixture and close the inlet;

[0086] 3) Start ventilation.

Embodiment 3

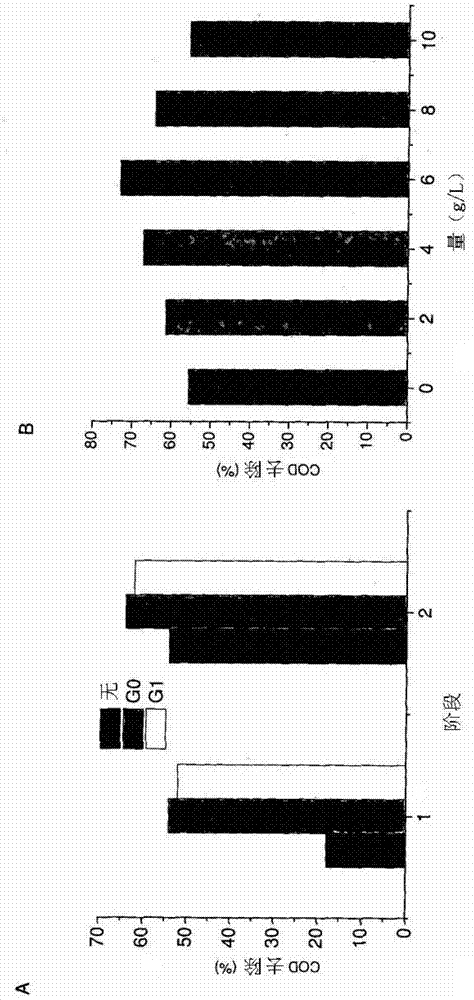

[0087] Example 3: Cultivation of sludge with additives: HDS for activated sludge process

[0088] When necessary, the HDS produced in Example 2 was taken out from the HDS outlet described in Example 1 30 minutes after the aeration was stopped. A certain amount of HDS was added to the AS pool so that the concentration of the additive ranged from 2 to 10 g / L. Several laboratory-scale AS pools were used simultaneously, and the operating parameters of the common AS method were maintained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com