Mire machine self-rescuing device

A technology of machinery and quagmire, which is applied to agricultural machinery, agricultural machinery and implements, and sowing. It can solve the problems of consuming a lot of manpower and material resources, and easily causing safety accidents. It achieves low manufacturing cost, convenient use, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

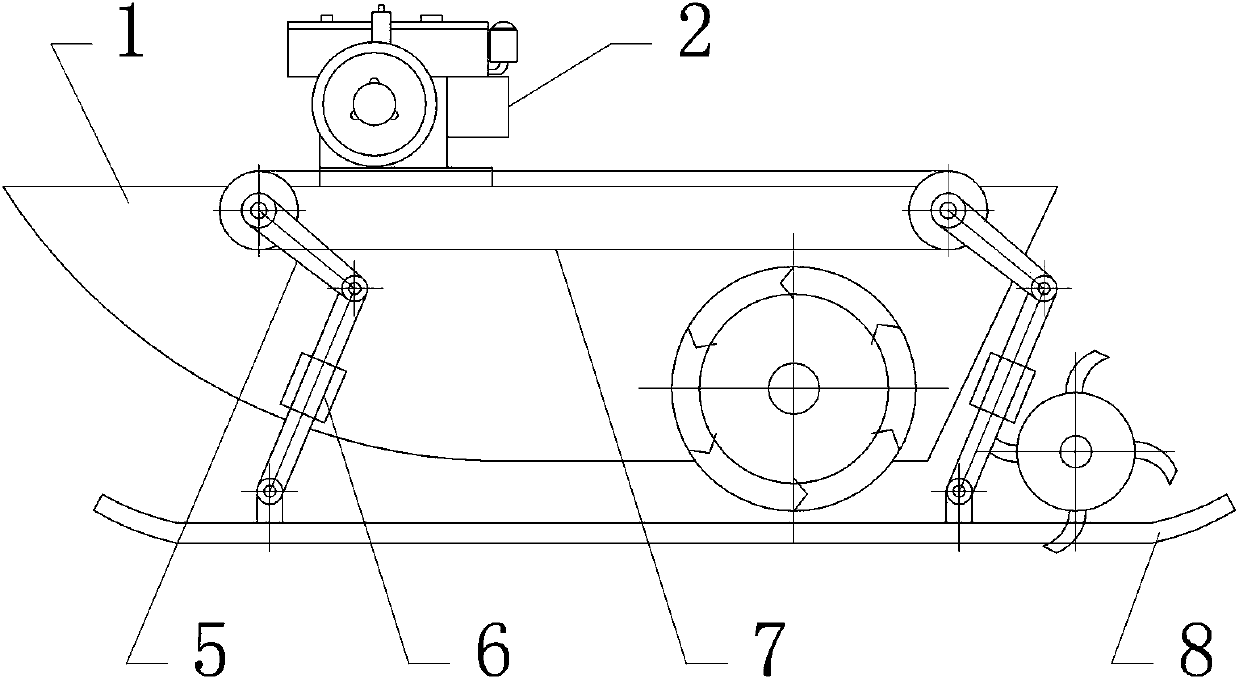

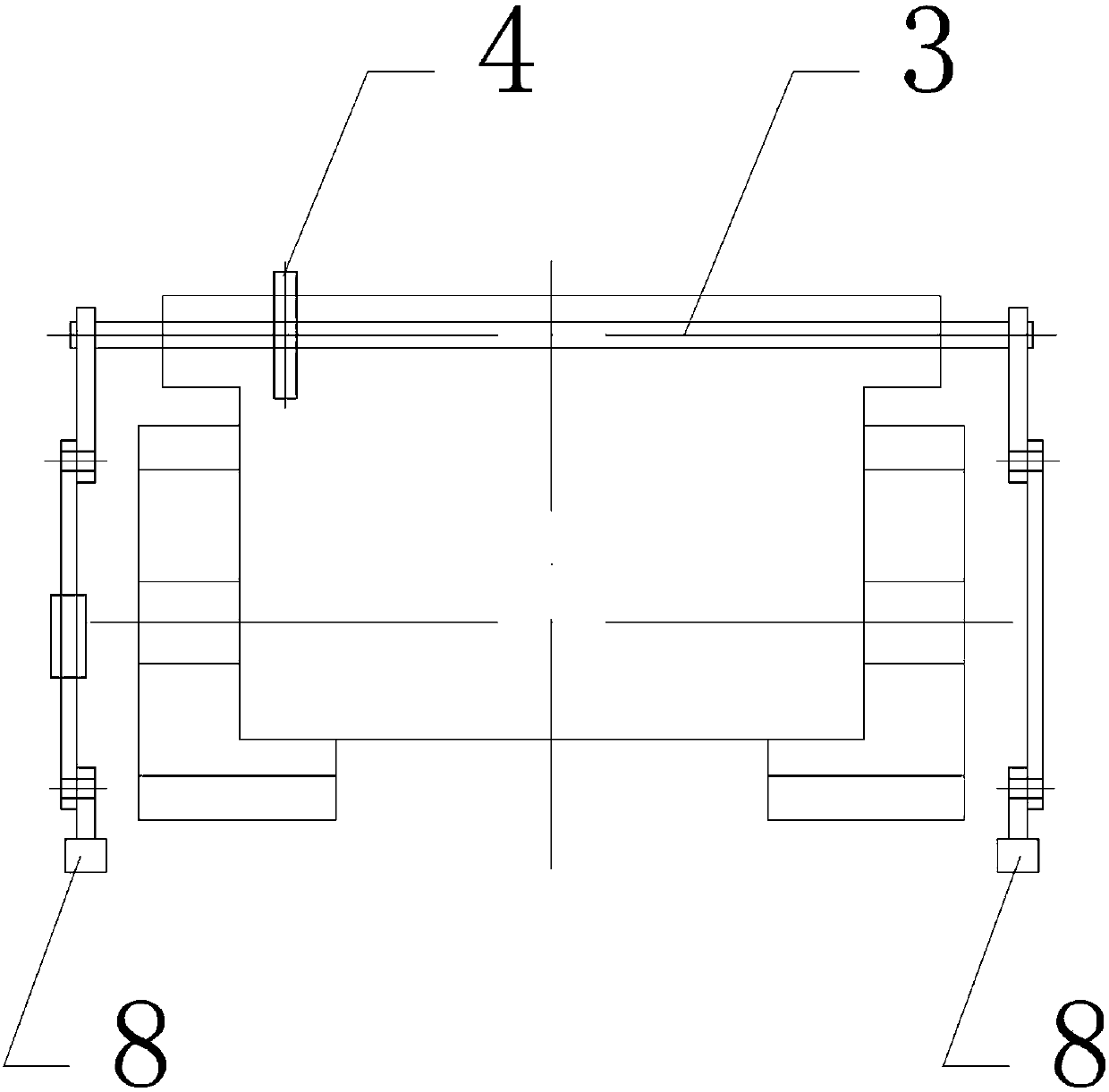

[0014] Embodiment 1, the present invention includes a main machine 1 and an engine 2, which is characterized in that: the main machine 1 is provided with an engine 2 to provide power for the entire device, the main machine 1 is equipped with a linkage axle 3, and the linkage axle 3 is provided with a linkage A linkage chain 7 is arranged between the sprocket 4 and the linkage sprocket 4. When the power output wheel chain is connected to the linkage wheel, the linkage axle 3 rotates synchronously through the linkage chain 7 between the linkage sprocket 4, so that all linkage axles 3 can be synchronized Movement, both sides of the linkage axle 3 are equipped with self-rescue lifting rocker arms 5, the linkage axle 3 drives the rocker crank mechanism to generate rotational motion, the other end of the self-rescue lifting rocker arm 5 is connected to the self-rescue lifting rocker arm 6 5 drives the self-rescue adjustable lifting connecting rod 6, the self-rescue adjustable lifting...

Embodiment 2

[0015] Embodiment 2, the present invention is provided with two or more interlocking axles 3, and the number of interlocking axles 3 can be appropriately adjusted according to actual factors such as the length of the main machine 1. Front side and rear side, if want other special requirements, also can be arranged on the middle part or other required positions, linkage axle 3 two ends protrude main body machine 1 both sides, reserve space for the installation of other parts such as self-rescue lifting rocker arm 5. refer to Figure 1 to Figure 2 , all the other are with embodiment 1.

Embodiment 3

[0016] Embodiment 3, the skateboard 8 of the present invention is provided with protruding connecting parts corresponding to the number of linkage wheel shafts 3, and the protruding connecting parts are connected with the self-rescue adjustable lifting connecting rod 6. The skateboard 8 adopts an oval airbag-type movable skateboard, When the main machine 1 is in normal operation, the slide boards can be stored at the freeboard positions on both sides of the ship. refer to Figure 1 to Figure 2 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com