Vertical circular spraying chamber applied to powder spray-coating line

A technology of spraying line and spray booth, which is applied to the device for coating liquid on the surface, the cleaning method using gas flow, coating, etc., which can solve the problem of not meeting the production needs of enterprises, increasing production costs, and wearing parts Many problems, to achieve the effect of saving color changing time, reducing energy consumption, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

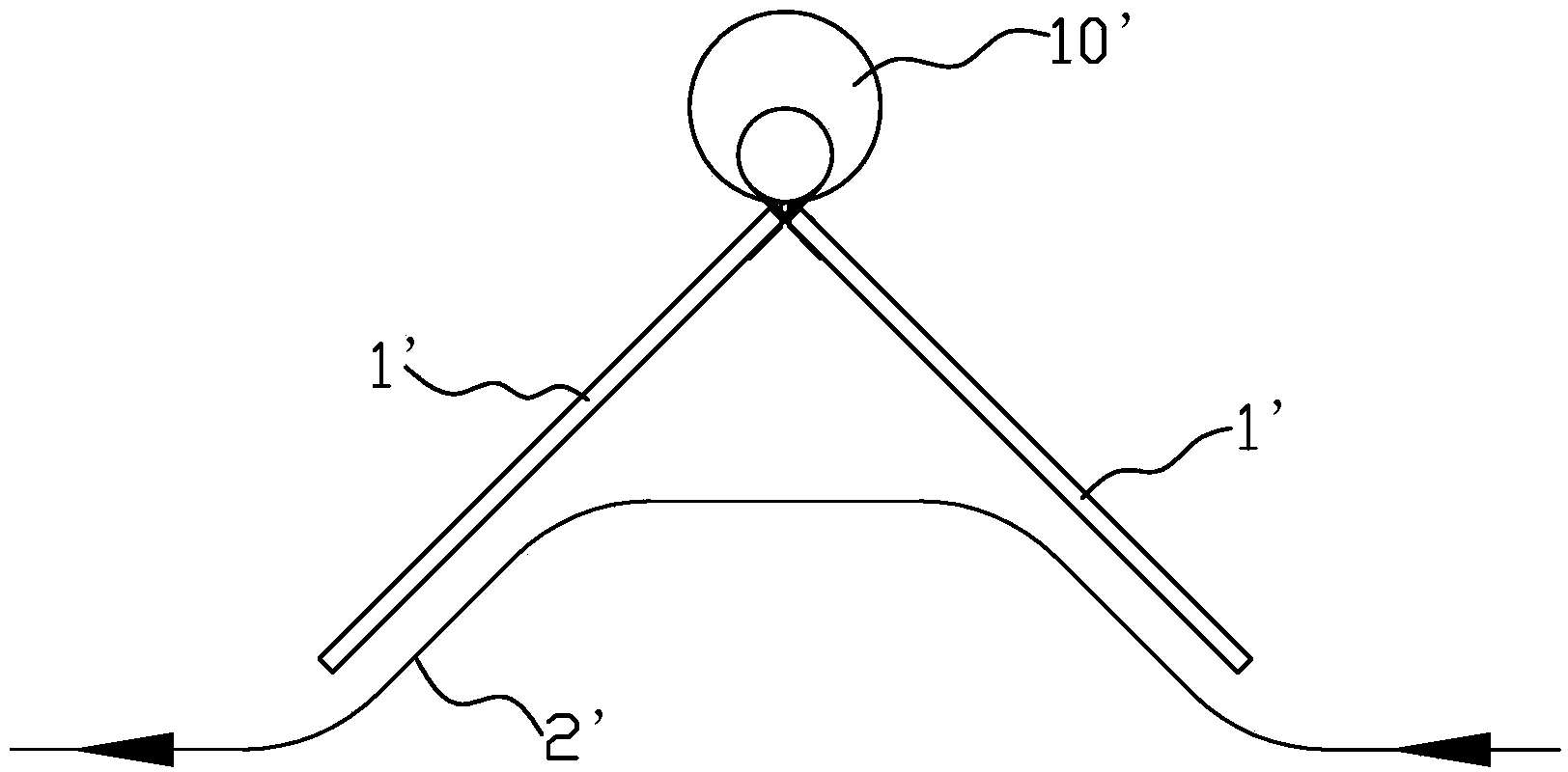

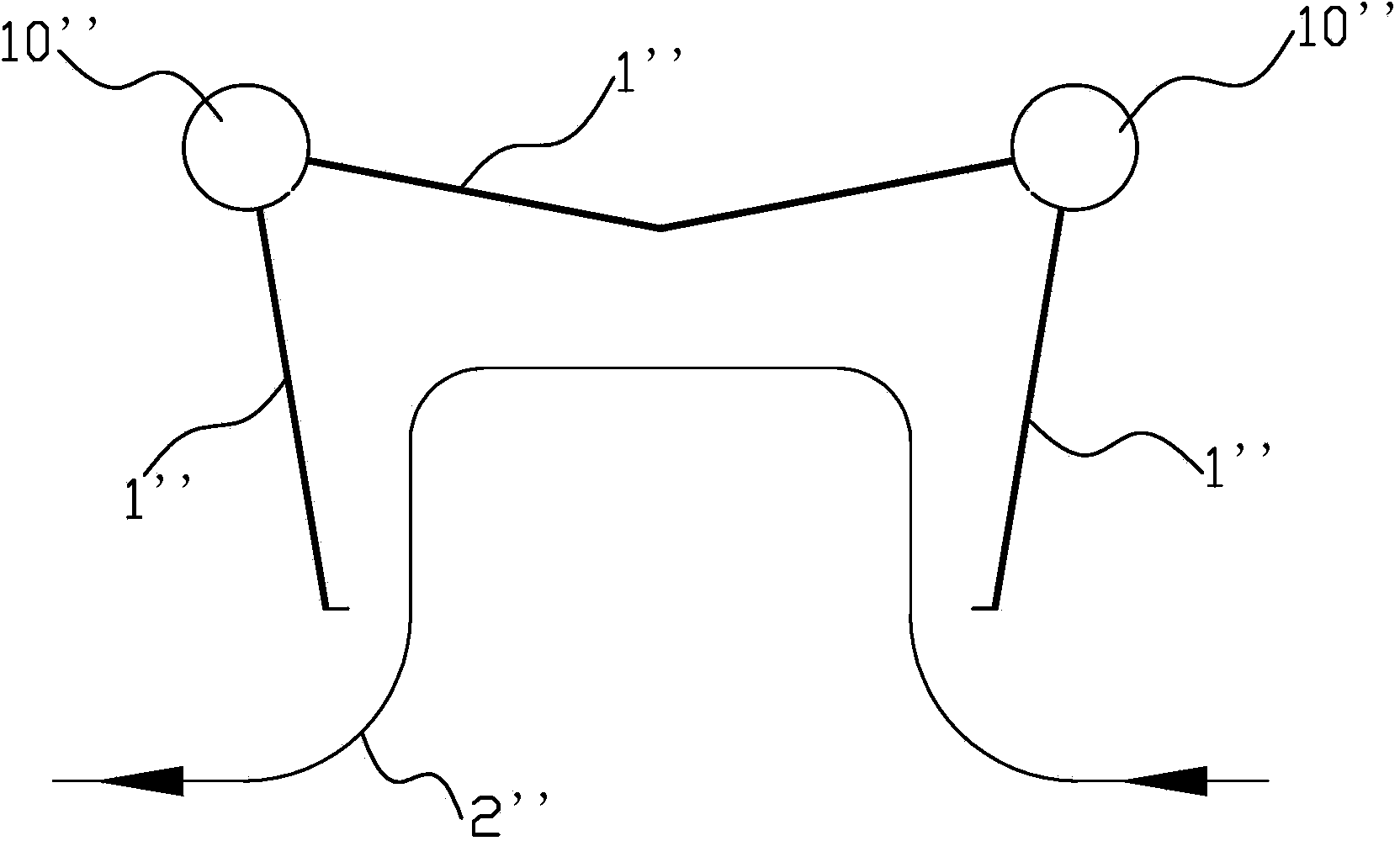

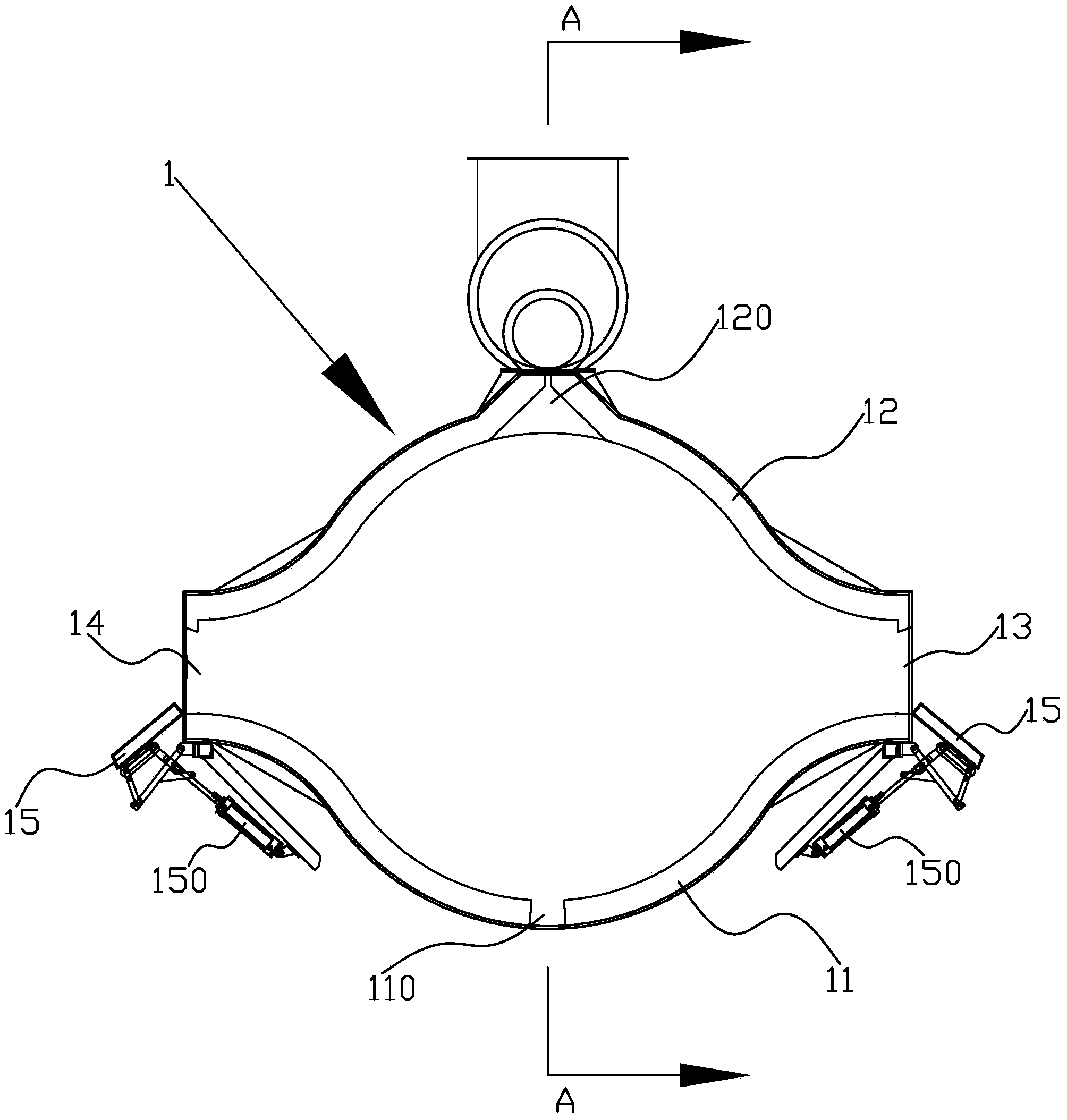

[0025] Reference image 3 To Figure 8, a vertical circular spray booth applied to a powder spraying line includes a vertical spray booth main body 1, which is mainly composed of a front side plate 11 and a rear side plate 12 located on the front and rear sides. The front side plate 11 and the rear side plate 12 are preferably made of plastic plates. Therefore, the front side plate 11 and the rear side plate 12 are not conductive, which reduces the production cost and facilitates spraying powder. To make the front side panel 11 and the rear side panel 12 have sufficient strength, the front side panel 11 and the rear side panel 12 are made of PP panels with a sandwich structure. Of course, the front side panel 11 and the rear side panel 12 are made of single-layer plastic panels or other Insulating materials are also possible; the middle parts of the front and rear side plates 11, 12 are arched outward to form an arc shape, so that the appearance of the spray booth body 1 looks li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com