Die cutting machine detection method

A detection method and die-cutting machine technology, which is applied in metal processing and other fields, can solve problems such as delays in die-cutting work progress, damage to die-cutting machines, and delays in die-cutting efficiency, so as to improve work efficiency and avoid misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

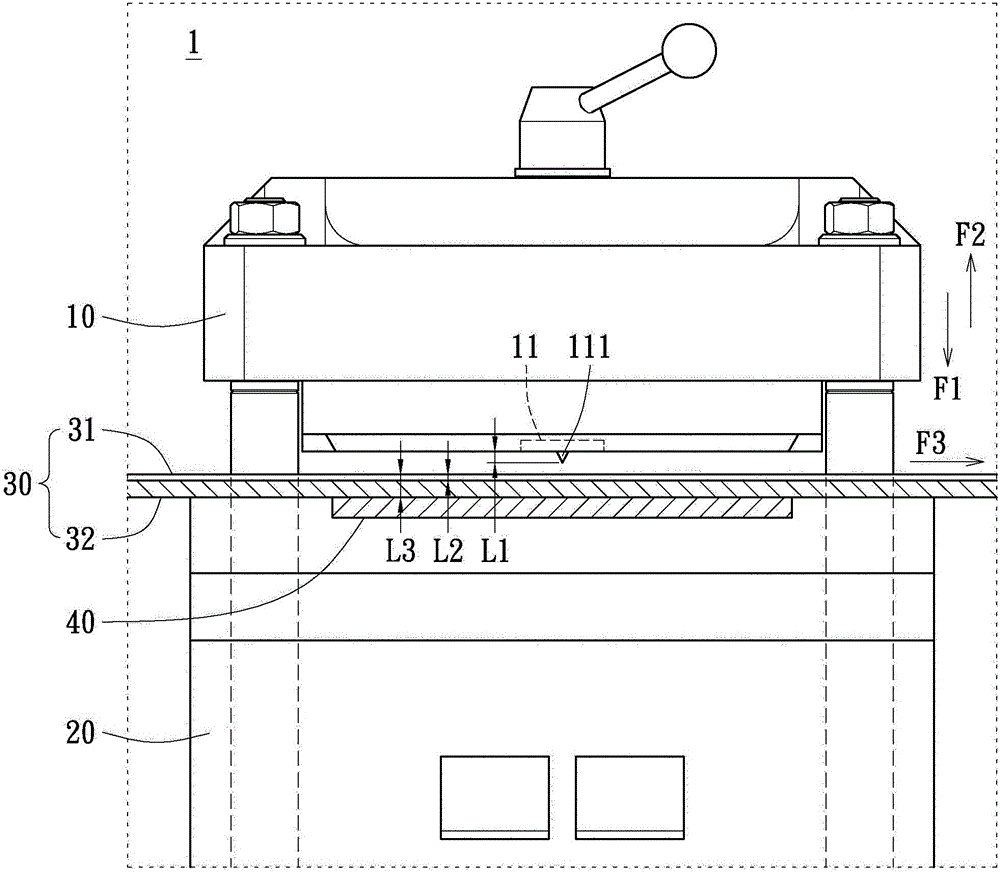

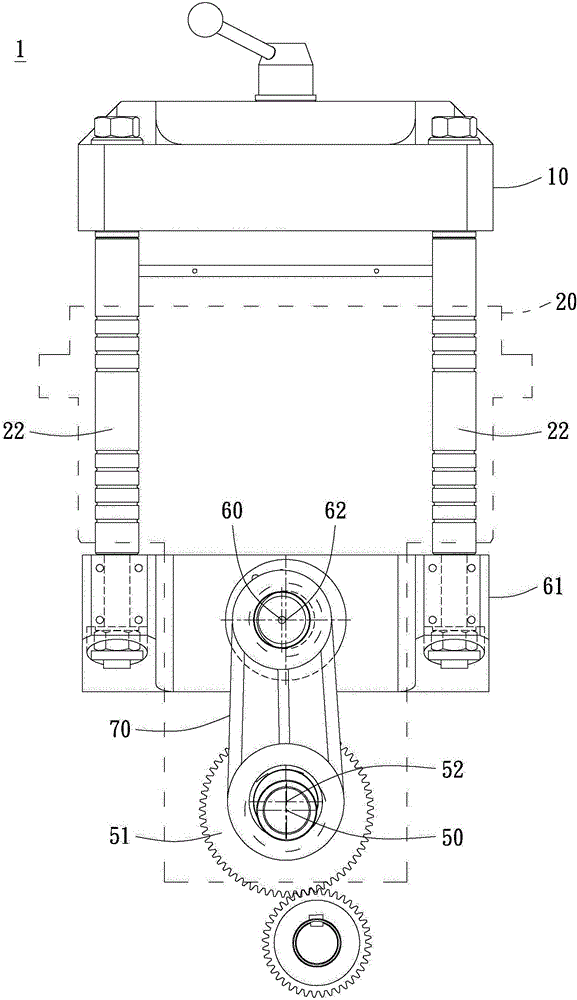

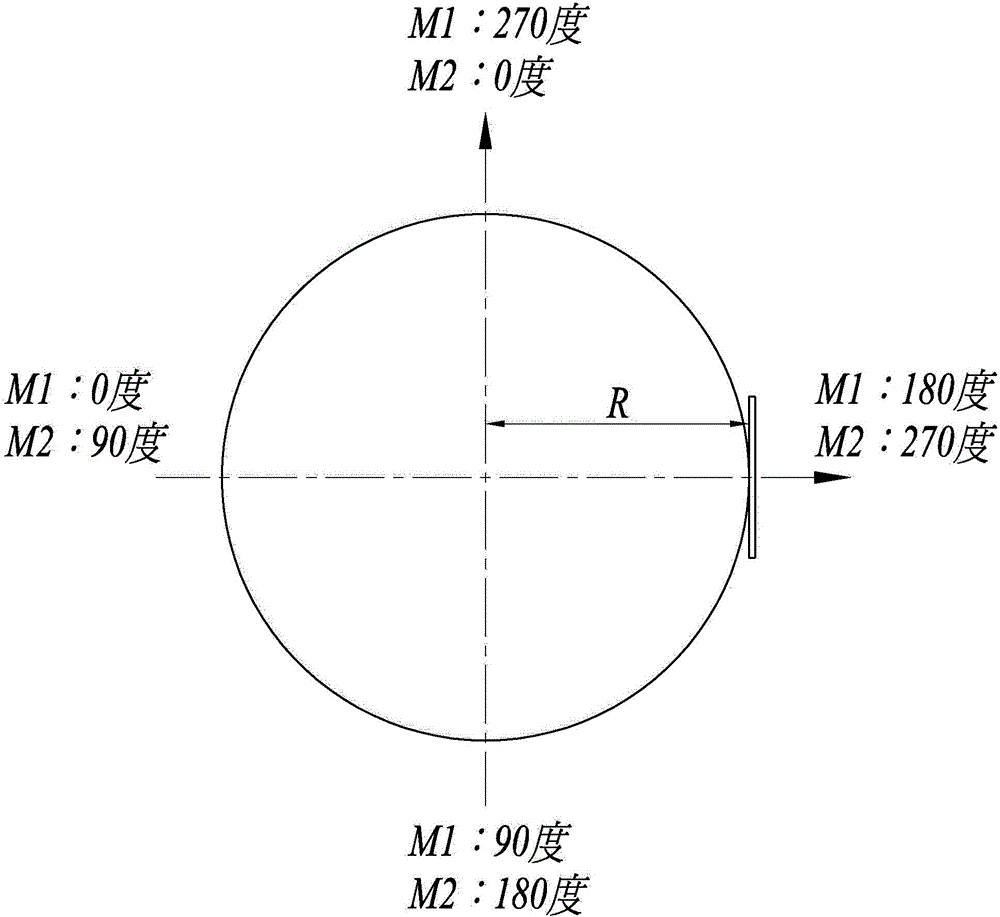

[0045] see figure 1 and Figure 5 As shown, the present invention provides a method for detecting a die-cutting machine. The die-cutting machine 1 at least includes a knife seat 10 and a processing seat 20 corresponding to the knife seat 10. The knife seat 10 is equipped with a knife die 111, and the knife die 111 Located on a die holder 11 of the cutter holder 10, a base paper 30 and a supplementary material 40 are laid on the processing base 20. The base paper 30 includes a side material 31 and a release paper 32. When the die-cutting machine is tested, a knife is installed The knife seat 10 of the mold 111 can move up and down along the cutting direction F1 or the return direction F2, and if the knife seat 10 moves up and down during the die-cutting process, the bottom paper 30 on the processing seat 20 will be fed along the paper feeding direction. Direction F3 continues to convey.

[0046] Die-cutting machine detection method of the present invention comprises the follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com