Strapping machines and strapping systems for cardboard stacks of cigarette packs

A strapping machine and cardboard technology, applied in the field of strapping machines and strapping systems, can solve the problems of unsatisfactory automation, high-efficiency production, different paper film belts, and low bundling efficiency, so as to achieve strong film feeding stability and save utilization Good effect of space and bundling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

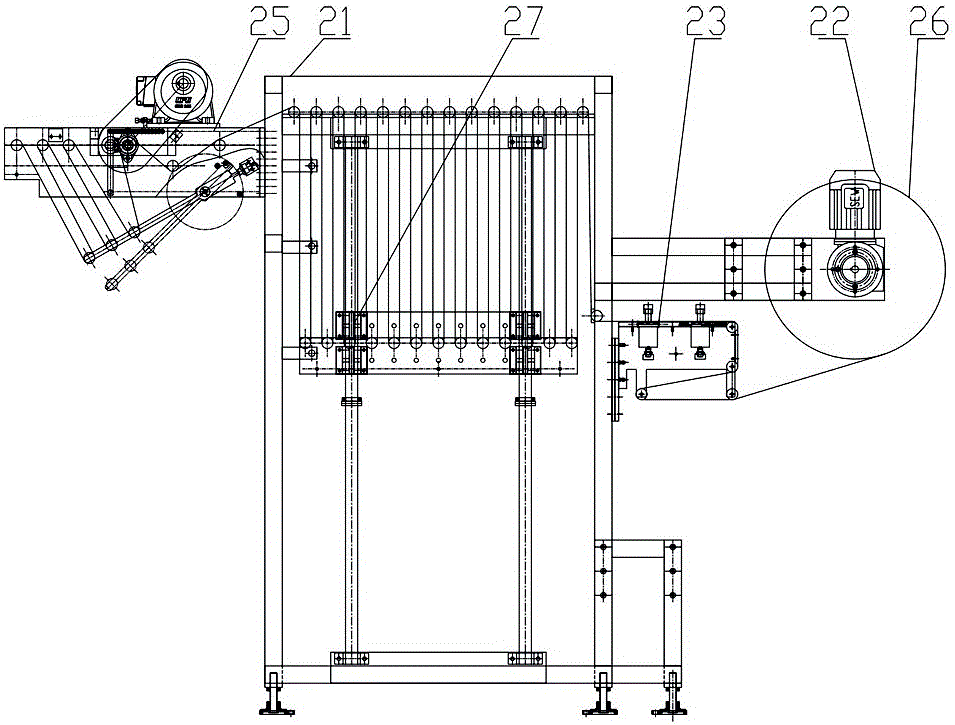

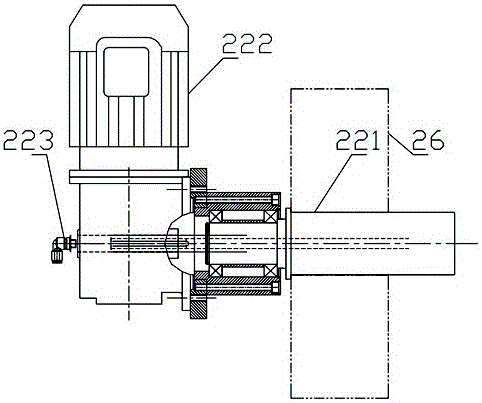

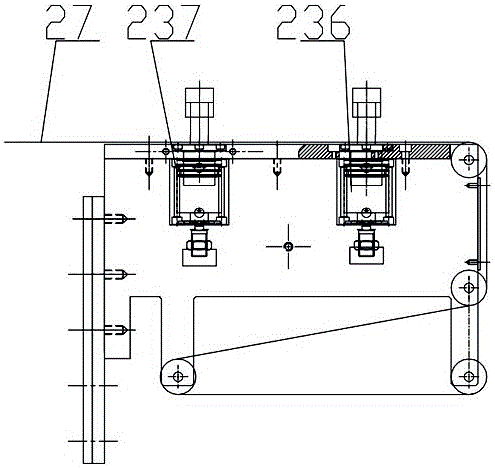

[0056] a kind of like Figure 11 and Figure 12 Shown the present invention is used for the strapping machine of cigarette box cardboard stack, comprises frame 1, and the middle part of frame 1 is provided with the working platform 8 that stops for cigarette box cardboard stack 11 to accept binding packing, the place ahead of working platform 8 (that is Facing the direction of the film feeding device and the cigarette case cardboard stack feeding device matched with the strapping machine, a drooping supply area 81 is provided, and the film belt sent out by the film feeding device 2 matched with the strapping machine is used for bundling and packaging the cigarette case cardboard stack 11 27 naturally droop from top to bottom to the drooping supply area 81 (see Figure 13 ), the front of the drooping supply area 81 is provided with a push mechanism 12, and the push mechanism 12 pushes the cigarette case cardboard stack 11 together with the drooping film belt 27 to the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com