Recovery Furnace Based on Efficient Electromagnetic Induction Heating for Scrap Nickel, Copper and Zinc Metal Materials

An electromagnetic induction and copper alloy technology, applied in metal recycling, electric furnace heating, recycling materials, etc., can solve the problems of long transmission path of processed objects, low efficiency of processing system, low cooling efficiency of low temperature, etc., to improve heat conduction efficiency and operation Simple and fast, the effect of improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A high-efficiency electromagnetic induction heating based waste nickel copper zinc recovery furnace provided by the present invention will be described in detail below with reference to the accompanying drawings and specific examples.

[0019] In the following description, various aspects of the present invention will be described. However, those skilled in the art can implement the present invention by using only some or all of the structures or processes of the present invention. For clarity of explanation, specific numbers, arrangements and sequences are set forth, but it will be apparent that the invention may be practiced without these specific details. In other instances, well-known features have not been described in detail in order not to obscure the invention.

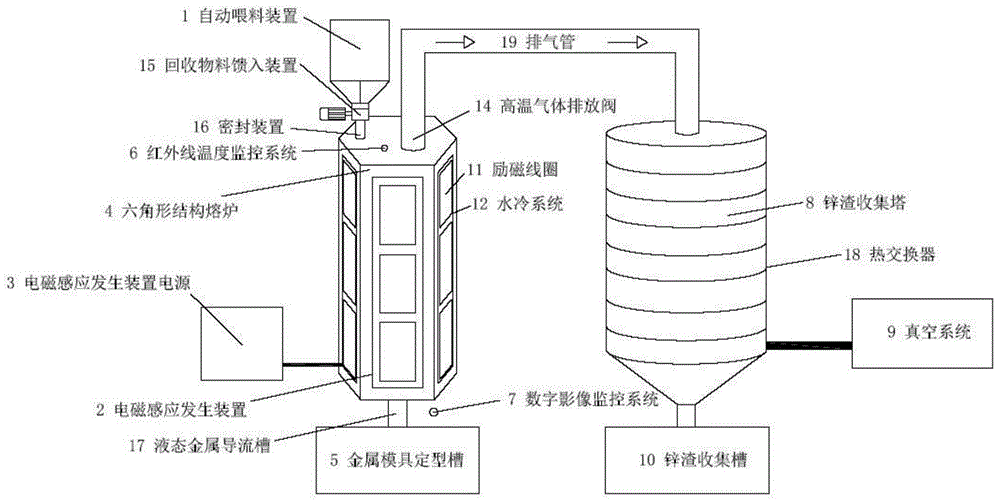

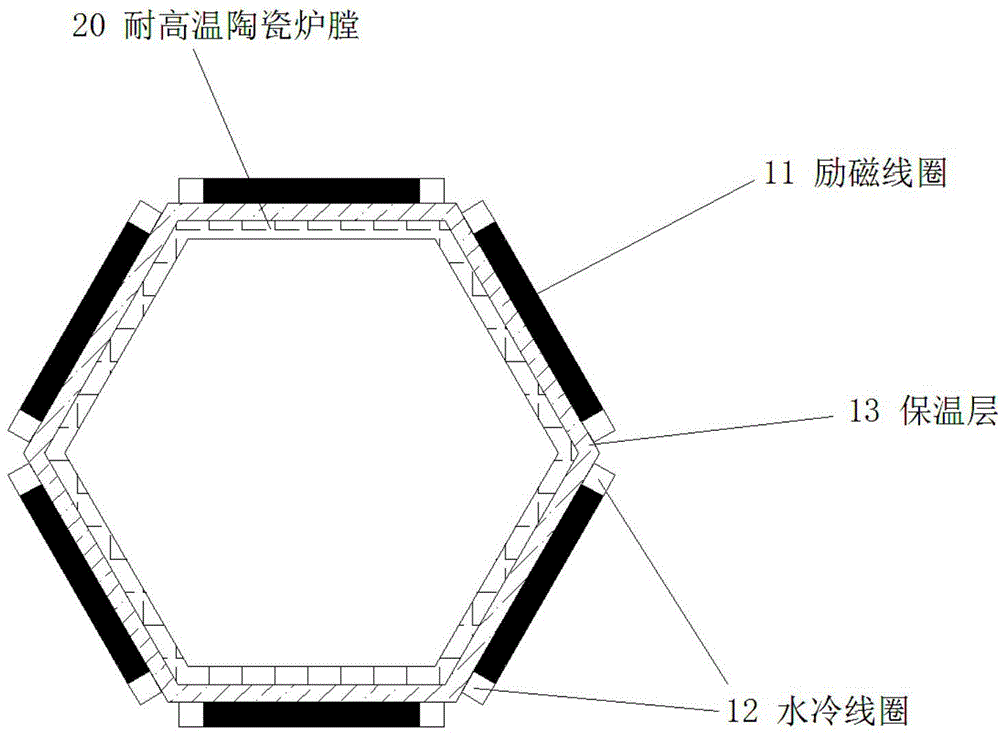

[0020] figure 1 It is the structural diagram of the waste miscellaneous nickel, copper and zinc metal material recovery system based on high-efficiency electromagnetic induction according to the applic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap