Porous floating breakwater suitable for long waves

A breakwater and hole-floating technology is applied in the field of ports and coastal hydraulic structures, which can solve the problems of poor deep-water long-wave wave absorption effect of breakwaters, difficult construction in soft foundation sea areas, and high cost, and achieves shortening construction period and wave absorption effect. Good, less affected by wave force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

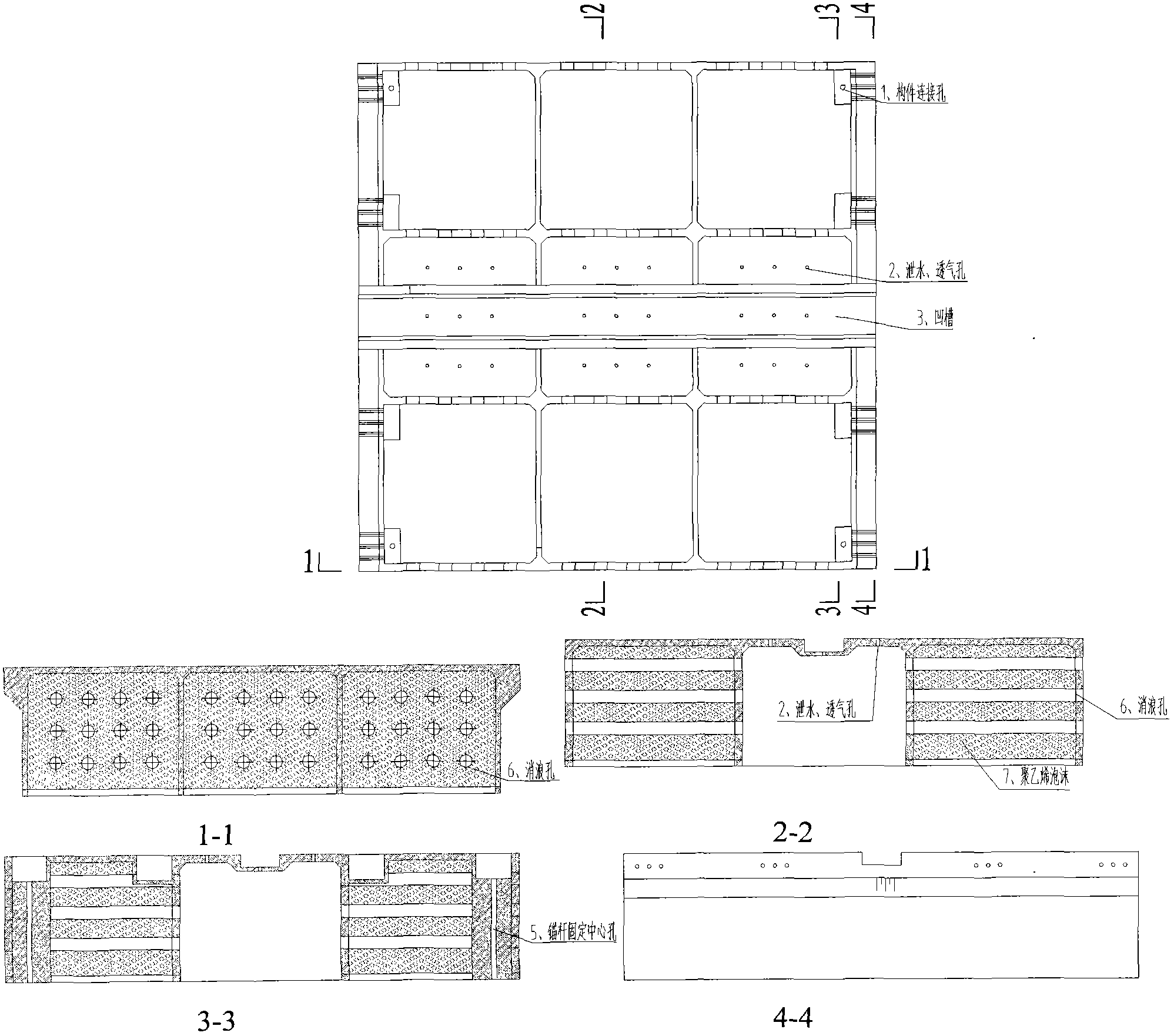

[0019] The specific implementation of this floating breakwater will be described below in conjunction with the accompanying drawings:

[0020] The size and interconnection of the floating components are determined according to the size of the water area, water depth, and wave conditions in the actual application area, so that the geometric size and arrangement of the breakwater fully meet the actual wave dissipation protection requirements.

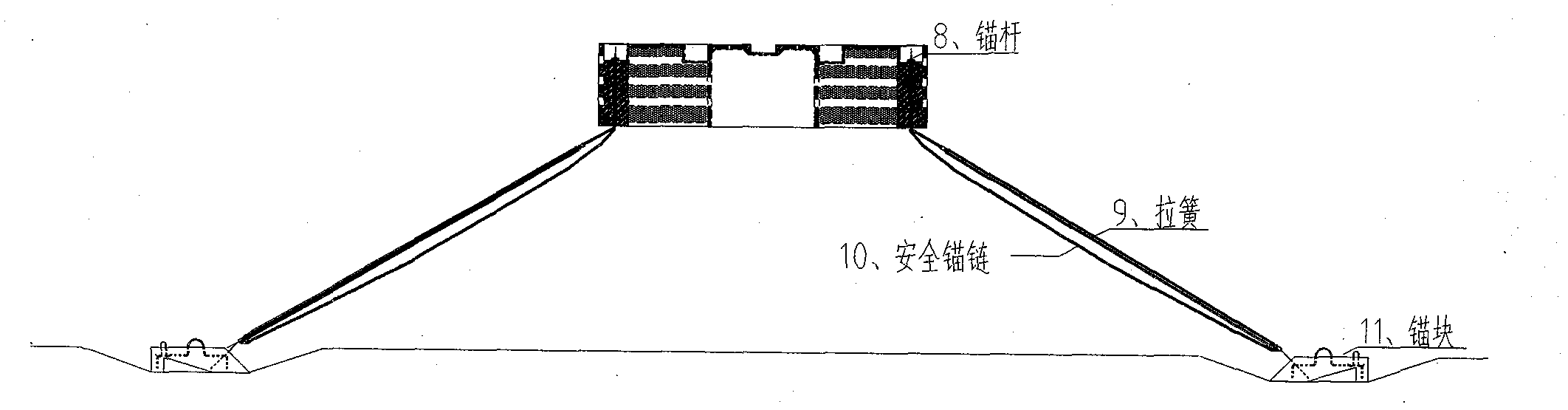

[0021] Approach 1: Breakwater with a single floating component

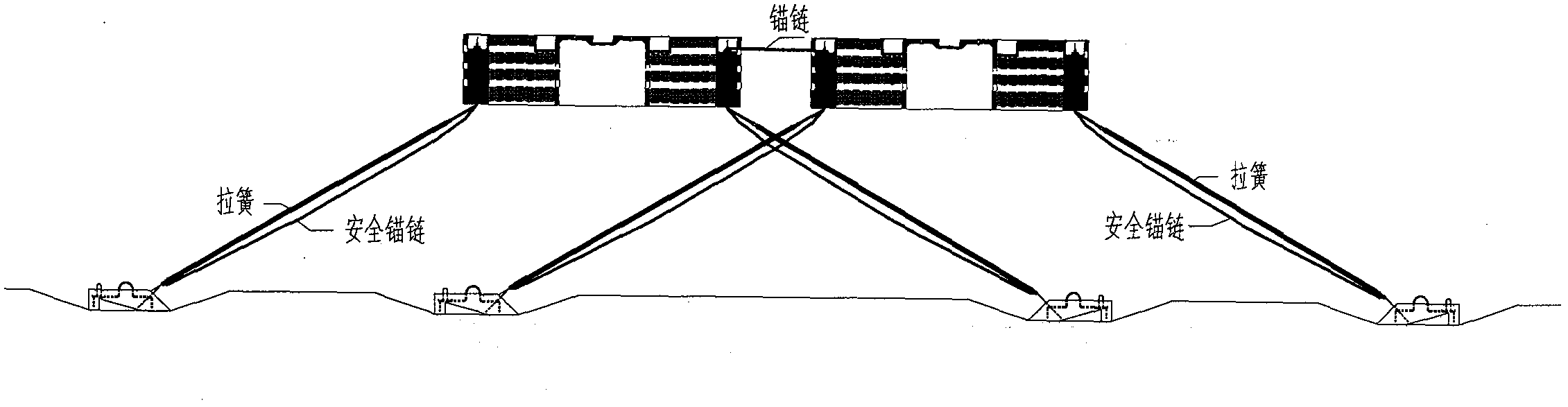

[0022] as attached figure 1 The floating breakwater shown is composed of three parts: floating components, mooring systems, and connecting devices between adjacent floating components. The floating component is a prefabricated thin-walled reinforced concrete floating body, and the cavity of the floating body is filled with polyethylene foam; the mooring system is composed of anchor rods and tension springs (such as figure 2 As shown), the four corners of the floating comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com