Drilling machine capable of pressing and pulling protective case

A technology for drilling rigs and casings, which is applied in the field of construction equipment for quickly pressing and pulling out casings, and can solve problems such as low construction efficiency, troublesome transitions, and low efficiency of lower casings, so as to improve construction efficiency, facilitate pile replacement, and expand The effect of construction scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The description in this part is only exemplary and explanatory, and the present invention can be implemented in many different ways defined and covered by the claims, which should not have any limiting effect on the protection scope of the present invention.

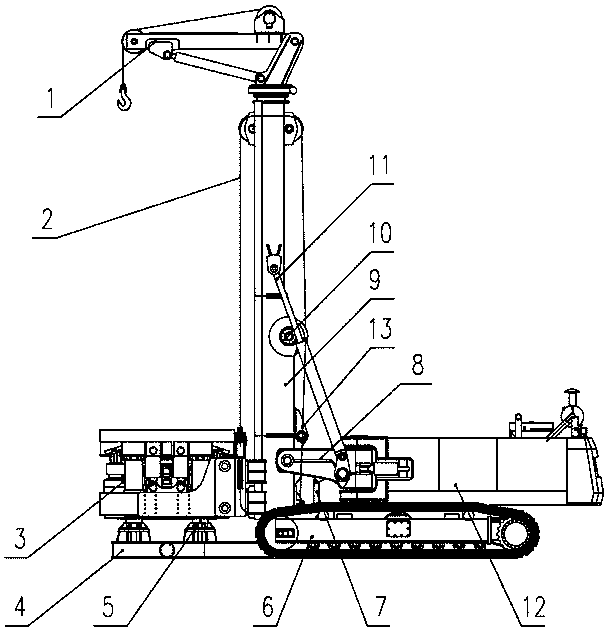

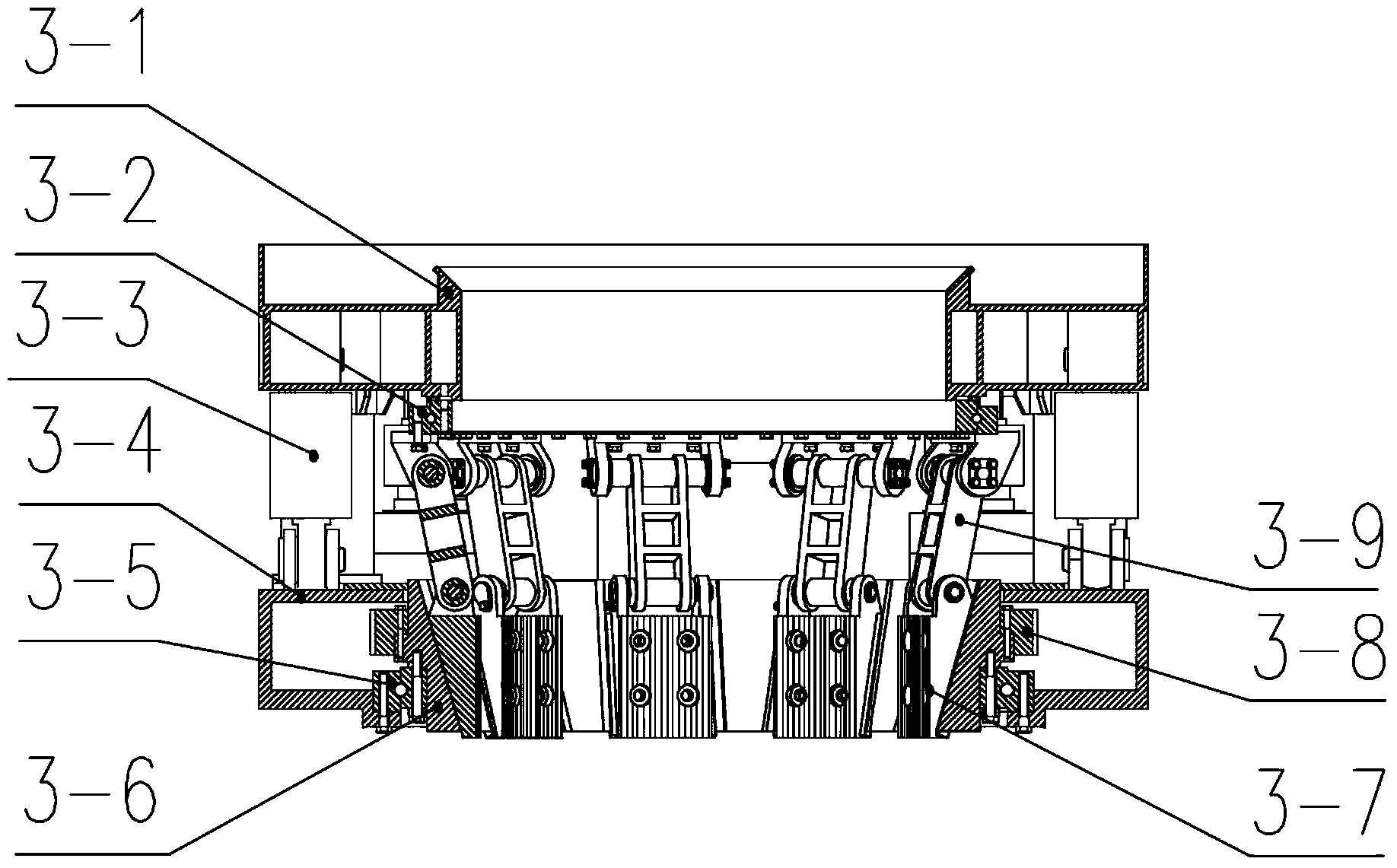

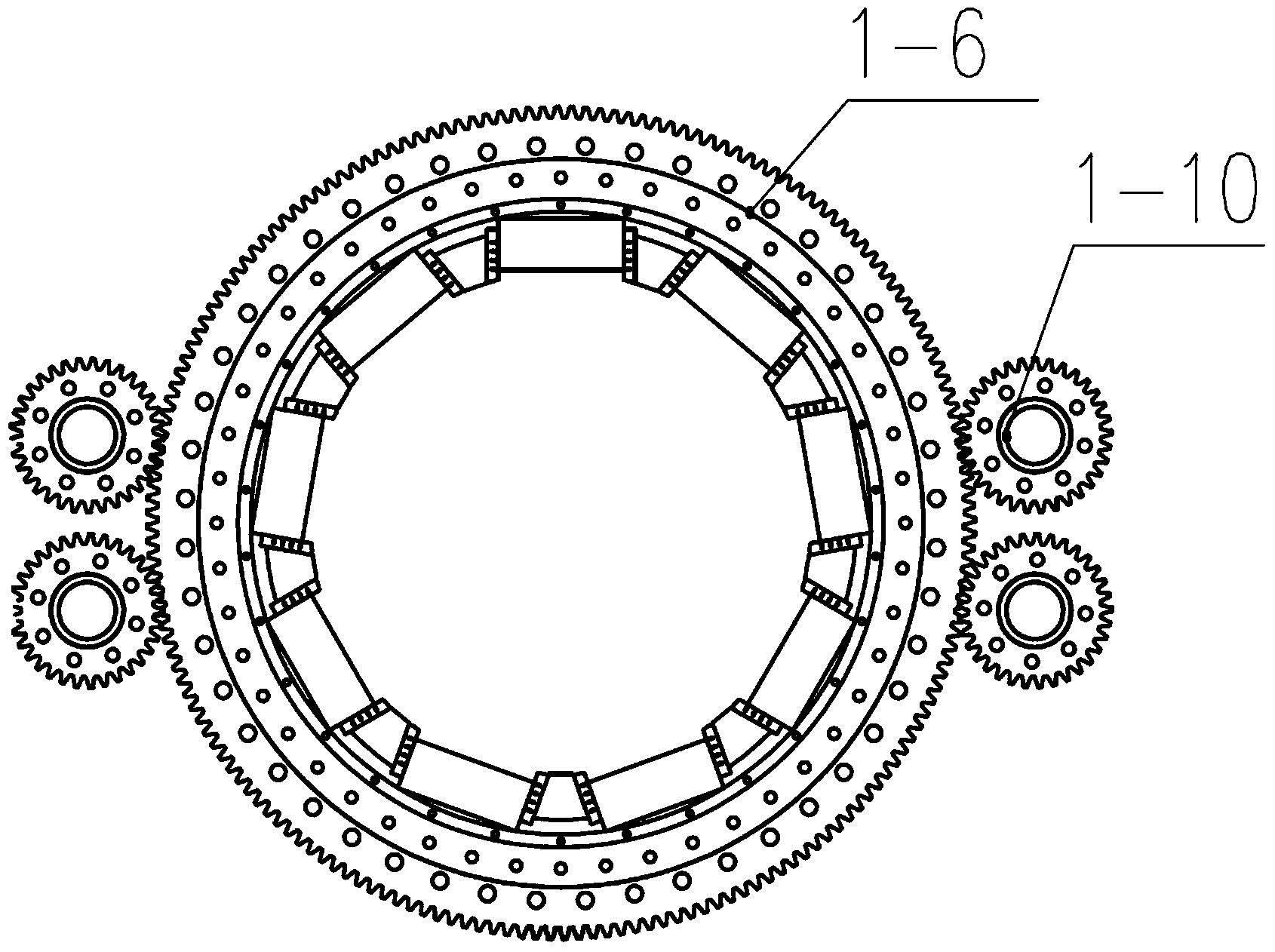

[0027] see figure 1 , including a crawler chassis 6, a platform 12 installed on the crawler chassis 6, a yaw mechanism 8 hingedly installed on the platform 12, a support rod 7 installed on the yaw mechanism 8, and a support rod 7 supporting the yaw mechanism 8; The mast 9 on the yaw mechanism 8, the vertical mast oil cylinder 11 hinged between the mast 9 and the yaw mechanism 8, the vertical mast oil cylinder 11 can change the angle of the mast 9, thereby changing the pile position is easy; There is a crane 1; a power head 3 is slidably installed on the mast 9; a support platform 4 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com