Hydraulic element detection system based on PLC (programmable logic controller)

A technology of hydraulic components and detection systems, applied in the field of detection systems, can solve problems such as inability to systematically store and record test data, inapplicability of hydraulic component monitoring, and narrow application range, so as to achieve the unity of cost and performance and facilitate popularization and use , to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

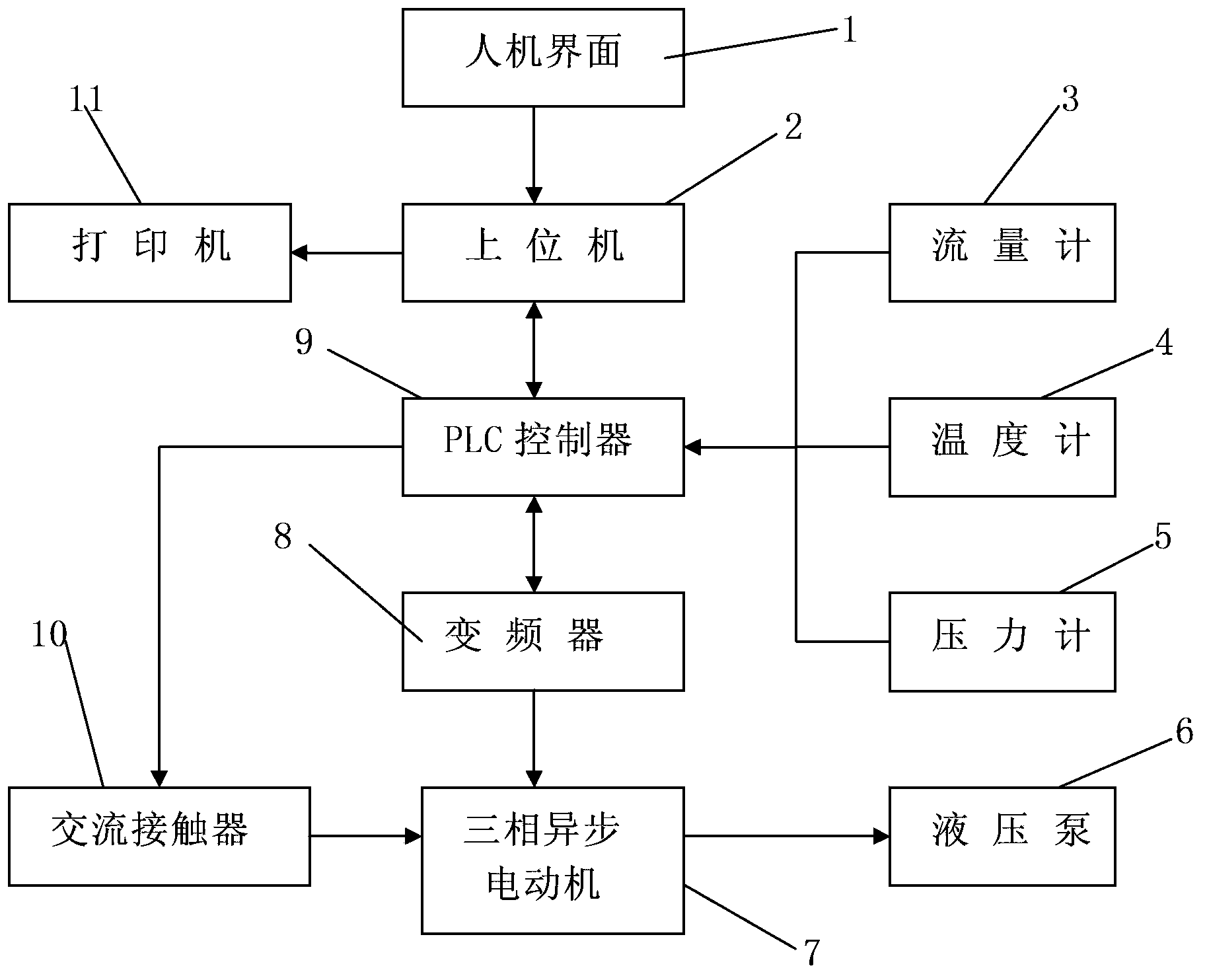

[0019] Such as figure 1 A hydraulic component detection system based on a PLC controller is shown, including a flowmeter 3, a thermometer 4 and a pressure gauge 5 respectively used to test the flow parameters, temperature parameters and pressure parameters of the measured hydraulic components in the hydraulic system, and receiving the The flowmeter 3, the thermometer 4 and the pressure gauge 5 output signals and the PLC controller 9 that controls the frequency converter 8 connected with the three-phase asynchronous motor 7, and the three-phase asynchronous motor 7 is used for hydraulic pressure in the hydraulic system Pump 6 provides power, the input end of described PLC controller 9 is connected with flowmeter 3, thermometer 4 and pressure gauge 5, and the output end of described PLC controller 9 is connected with AC contactor 10, and described AC contactor 10 It is connected with the three-phase asynchronous motor 7; the PLC controller 9 is connected with a host computer 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com