High-throughput detection method for grain form parameters

A detection method and high-throughput technology, applied in the field of crops, can solve problems such as insufficient grain shape parameters, and achieve the effects of accurate and reliable detection results, improved detection efficiency and stability, and efficient and accurate detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

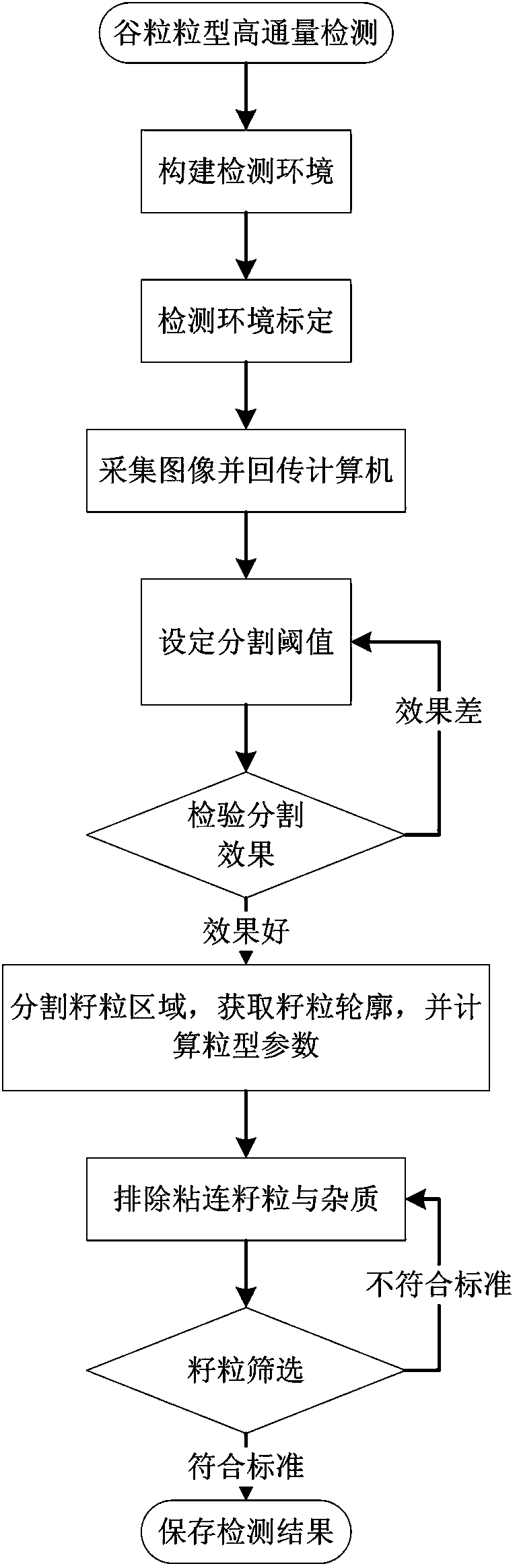

[0061] A high-throughput detection method for grain shape parameters, comprising the following steps,

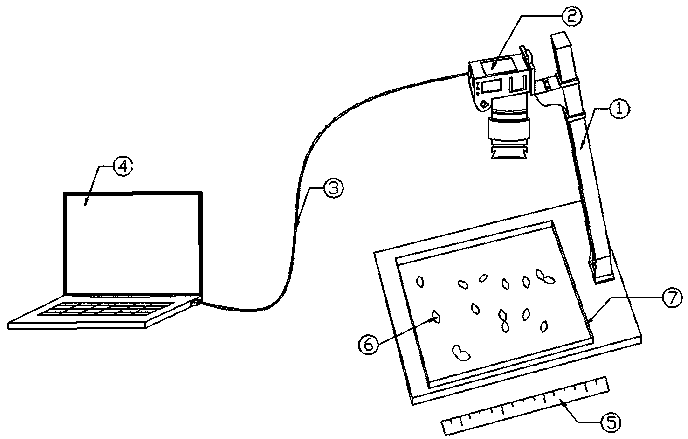

[0062] Step 1. Build a particle shape detection platform, such as figure 1 as shown,

[0063] On the horizontal workbench, fix the digital single-lens reflex camera 2 with the help of a remake stand 1 or a tripod;

[0064] The imaging plane of the above-mentioned digital single-lens reflex camera 2 is parallel to the workbench, and the height of the camera is set; the set height is used as a standard to obtain a more ideal imaging.

[0065] Place a tray 7 with a monochromatic background on the plane of the horizontal workbench to carry the grains to be tested; the color of the tray 7 is advisable to have a larger contrast with the color of the grains;

[0066] The digital SLR camera 2 is connected with the computer 4 through the camera connection line 3;

[0067] Turn on the real-time view mode of the digital SLR camera to display the real-time imaging information of the ca...

Embodiment 2

[0101] 1. Build the shooting environment according to the specifications provided by the technical solution of the present invention, start the image processing software in the computer (hereinafter referred to as the software) and establish a connection with the camera, and switch the software to the "live view" mode.

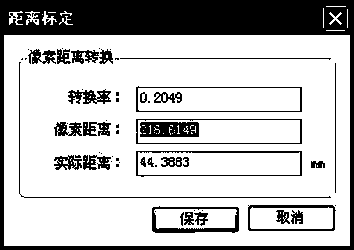

[0102] 2. Place the calibration reference object in the grain tray, control the camera to capture the image of the reference object; the image of the reference object is sent back to the computer, and the software switches to the "analysis" mode.

[0103] 3. Select the calibration function, left-click the starting point of the scale in the reference object image; move the mouse to the end point of the scale, and click the left mouse button again; at this time, the pixel connection line between the start point and the end point is drawn in the reference object image and displayed The number of pixels between two points. If you are not satisfied with this select...

Embodiment 3

[0112] 1. Use the calibrated grain shape parameters to detect the environment, spread the sample grains in the grain tray, observe the samples to be tested through the "real-time view" function, and when the sample distribution meets the detection requirements, control the camera to collect grain images and send them back To the computer, switch the detection software to "analysis" mode.

[0113] 2. Select the "parameter detection" function, and the software will load the conversion rate and segmentation threshold saved by the software to perform image segmentation; the segmented grain target area will be labeled and its outline will be obtained, and then the morphological characteristic parameters of the grain will be obtained; and according to the setting Set the threshold for noise screening.

[0114] 3. The parameter detection result will be superimposed with the collected grain image and displayed in the main work area, and the area label will be displayed in the lower ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com