High-pressure fatigue testing device and method

A fatigue test and test device technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of complex system, poor reliability, small flow rate, etc., and achieve low energy consumption, high reliability, and large driving force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

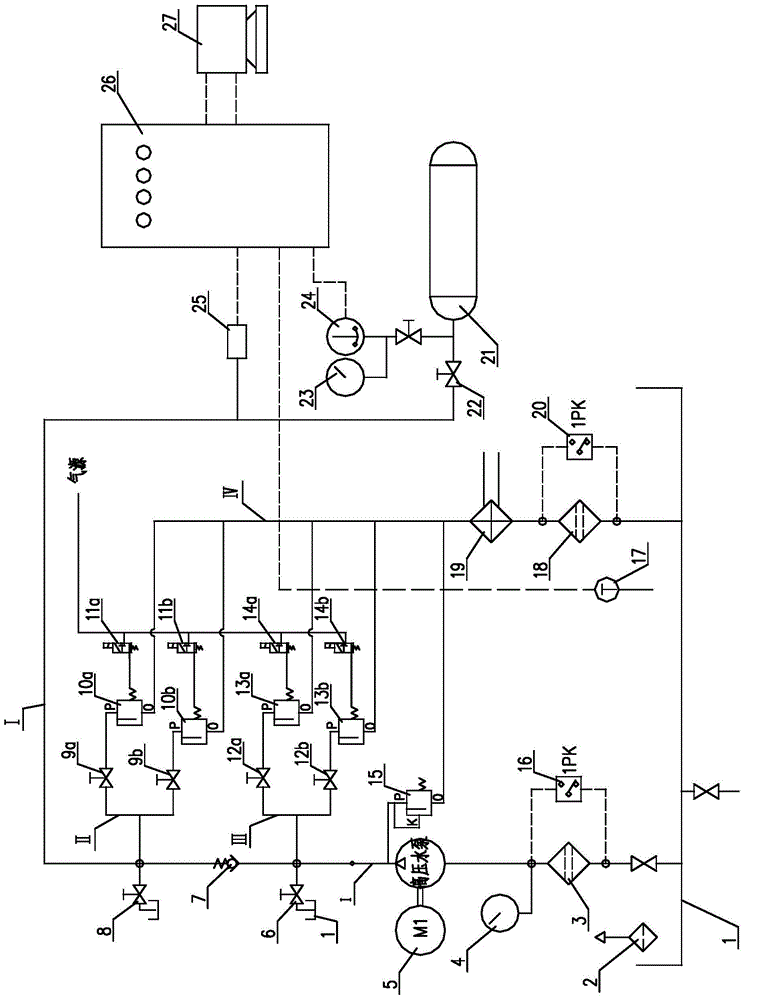

[0028] Below in conjunction with accompanying drawing, the implementation process of test device among the present invention is further described:

[0029] see figure 1 , This embodiment consists of a hydraulic unit, a pressure relief unit and a control unit.

[0030] Such as figure 1 As shown, a water tank 1 is set in the hydraulic unit, and a high-pressure water pump motor unit 5 is used as a power source. A high-pressure filter 3, a throttling and pressure regulating valve 15, a liquid supply check valve 7 and a high-pressure cut-off valve are sequentially set in the main hydraulic pipeline 1. Valve 22, the main hydraulic pipeline 1 is also provided with a manual pump end high-pressure cut-off valve 6 and a manual test piece end high-pressure cut-off valve 8 on both sides of the pipeline connected to the liquid supply check valve 7, which can control the pressure of the test vessel and the pressure test pump. The high pressure is manually unloaded.

[0031] The pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com