Electrical control system and synchronizing device for three-strand tire cord straight twisting machine

An electrical control system and direct twisting machine technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as inconvenient installation and maintenance, substandard strength retention rate, large twist deviation, etc., and achieve overall Good performance, improved communication efficiency, and improved force retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

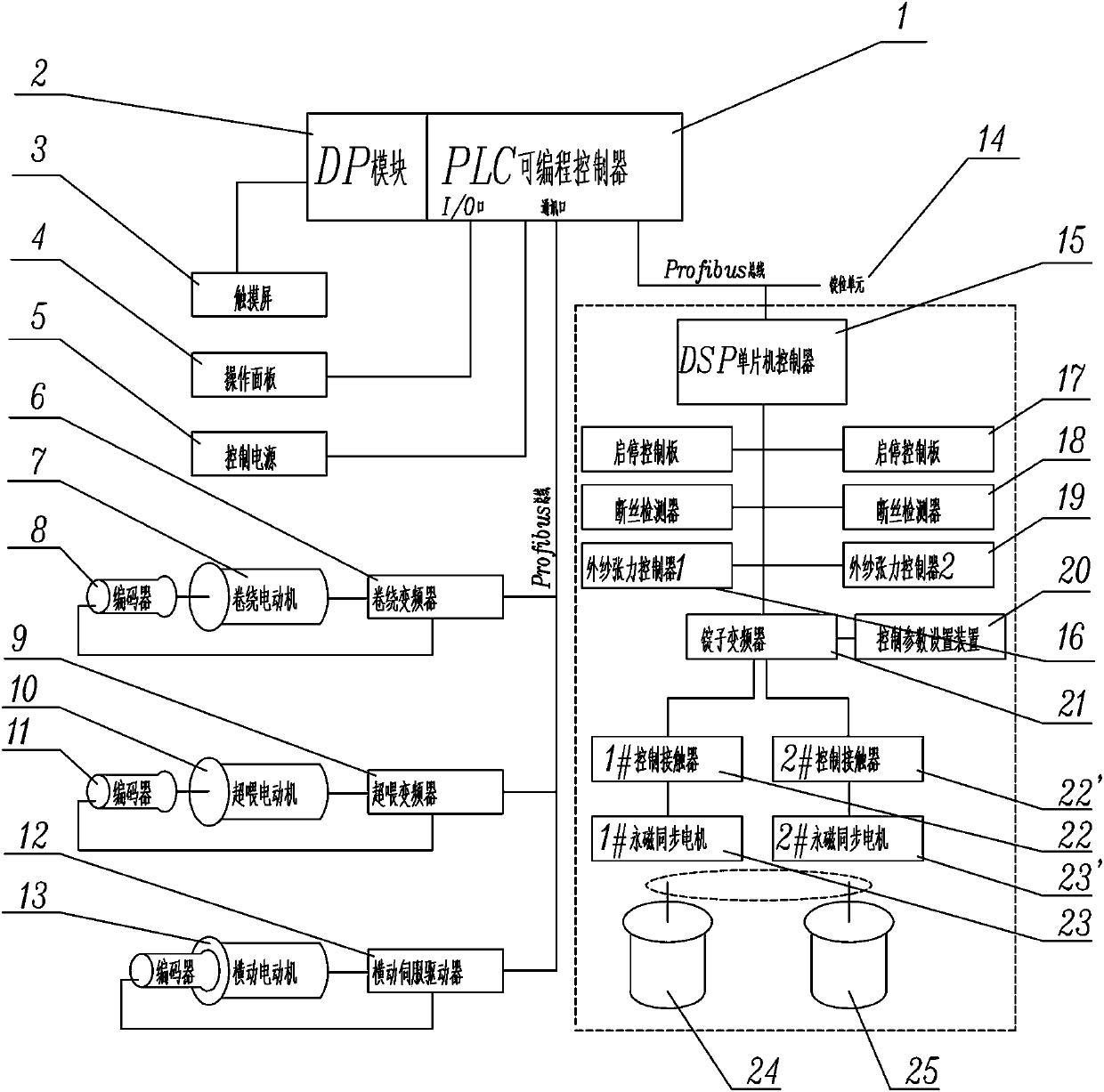

[0031] Such as figure 1 Among them, an electrical control system for 3-strand cord direct twisting machine, including PLC programmable controller 1, PLC programmable controller 1 is electrically connected with a plurality of spindle position units 14, 42 spindle positions are used in this example Unit 14. Preferably, the PLC programmable controller 1 is Siemens S7-200, 300 series.

[0032] Preferably, the PLC programmable controller 1 communicates with each component through the communication module 2 of the PROFIBUS-DP bus, and the PROFIBUS-DP module adopts Siemens EM277.

[0033] PLC programmable controller 1 is also electrically connected with touch screen 3 , operation panel 4 and control power supply 5 . Among them, the touch screen 3 adopts Siemens MP277, and the operation panel 4 includes buttons, indicator lights and safety switches.

[0034] Each spindle unit 14 is provided with a single-chip controller 15, the single-chip controller 15 is electrically connected to...

Embodiment 2

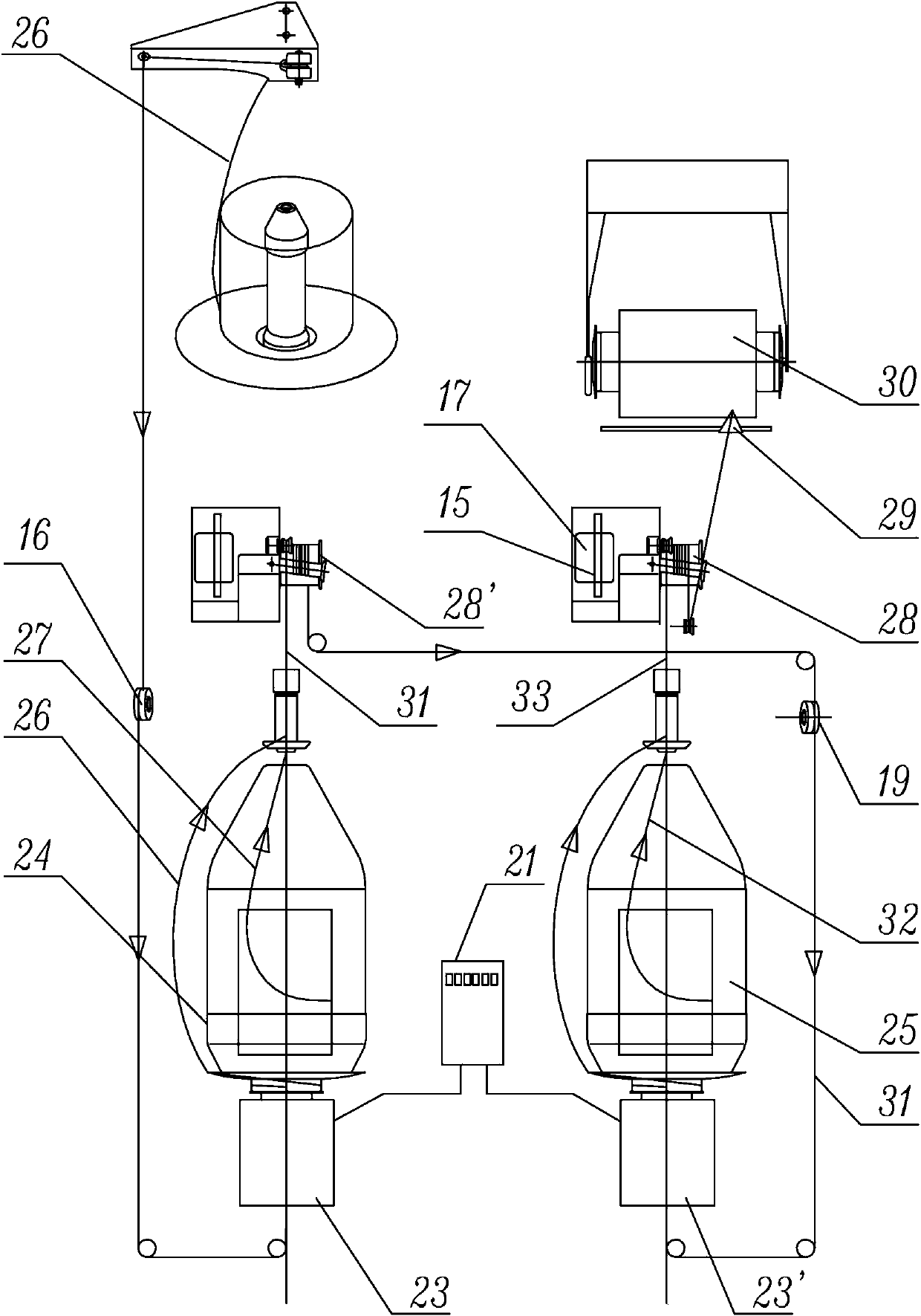

[0056] Such as figure 2 Among them, a spindle synchronization device for 3-strand cord direct twisting machine includes a first spindle 24 and a second spindle 25, a single-chip microcomputer controller 15 is electrically connected to a spindle frequency converter 21, and the spindle frequency converter 21 is simultaneously connected to the first spindle The first permanent magnet synchronous motor 23 of 24 is electrically connected with the second permanent magnet synchronous motor 23' of the second spindle 25, and the first permanent magnet synchronous motor 23 and the second permanent magnet synchronous motor 23' are synchronously driven by the spindle inverter 21 rotate.

[0057] The single-chip controller 15 is open-loop controlled with the first permanent magnet synchronous motor 23 and the second permanent magnet synchronous motor 23'.

[0058] In the present invention, an AC frequency converter is used to simultaneously drive two high-speed permanent magnet synchrono...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com