Non-tray case type cassette optical disk box and automated driving device thereof

A disc cartridge and trayless technology, which is applied to carrier storage devices, magazine/cassette containers, instruments, etc., can solve the problems of low efficiency, inconvenient exchange of disc cartridges, large volume, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

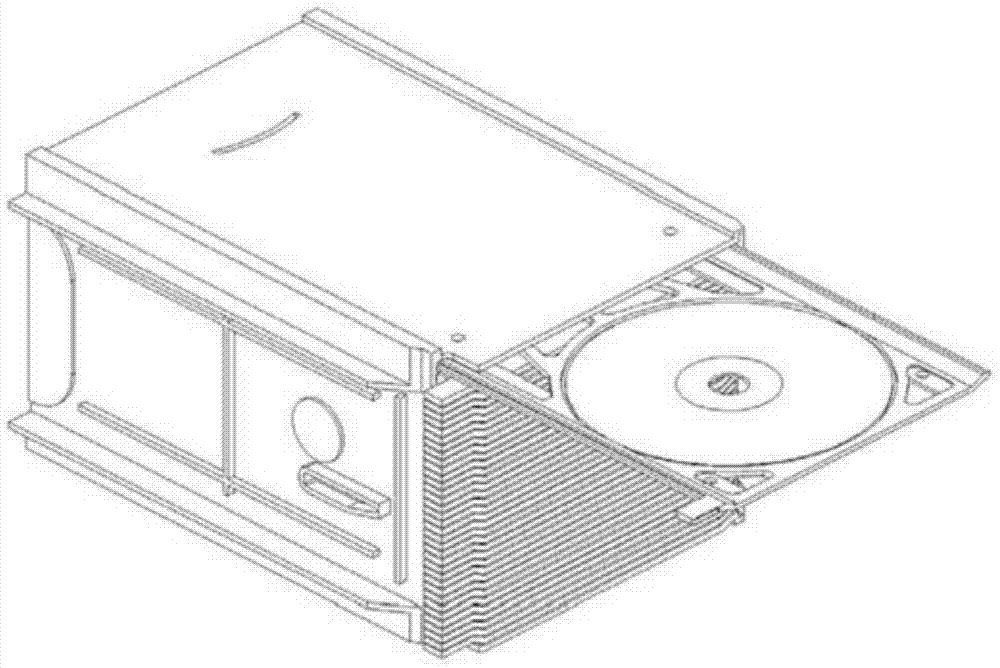

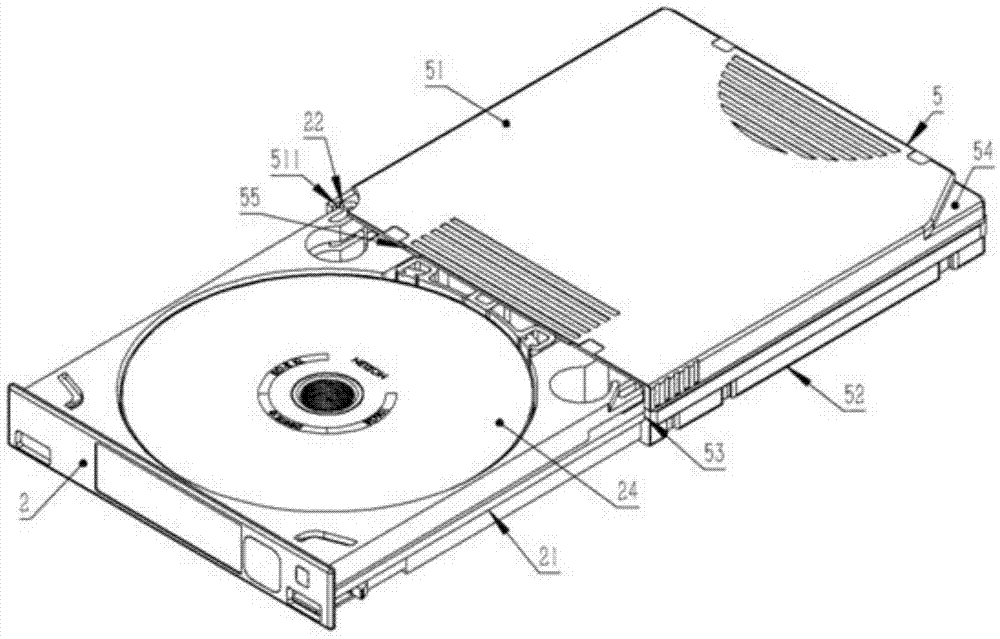

[0044] This embodiment has described a kind of trayless box-type cassette cassette, its structure is as follows Figure 3 to Figure 6 As shown, it includes an inner box 2 with a smooth inner wall, an upper cover 51 and a lower cover 52, and the upper cover 51 and the lower cover 52 fixed together constitute the optical disc case 5, and the optical disc case 5 has a fool-proof mechanism 54, This ensures that the disc case 1 is inserted in the correct direction. There are protruding inner box slide bars 21 on the two side walls of the inner box 2, and there are recessed shell inner grooves 53 on both sides of the inner wall of the disc cartridge shell 5 that are fitted with the inner box slide bars 21, so the inner box The case 2 can be smoothly drawn in the case 5 of the disc case.

[0045] The inner box 2 includes an anti-pull-out hook 22, a mechanical opening and locking mechanism 3, a transport protection device 23, and an identification device 4. The identification device ...

Embodiment 2

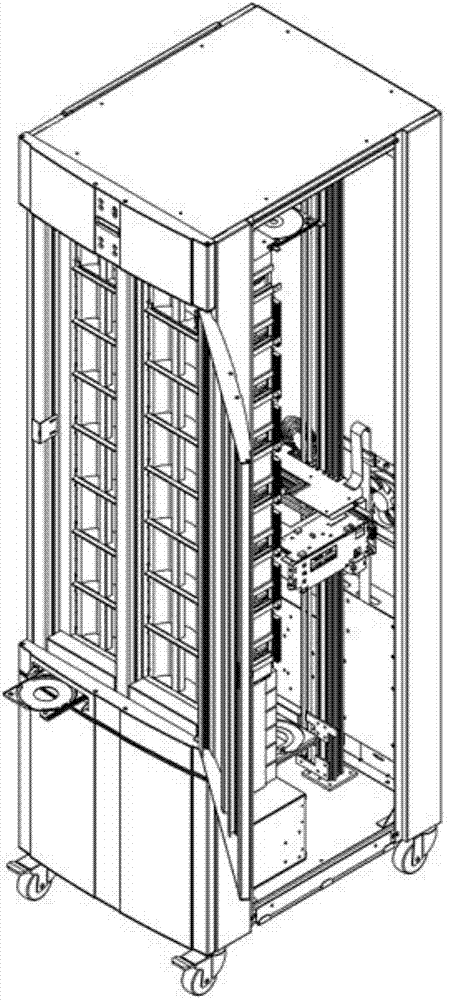

[0052] This embodiment describes an operation embodiment of an automatic drive device for the trayless cassette cassette, the drive device is as Figure 7 , 8 , including the disc cartridge input and output device 6, the hook 711 of the drawer, the ejector rod 712 of the drawer, the catcher 73, the read-write drive 8 for the disc, the elevator 7, the RFID card reader 92, the data interface 91, the control system 9, etc. , it can be realized that arbitrarily taking out an optical disc 24 from the optical disc case 1 and putting it into a standard optical disc read-write drive 8 for reading and writing operations, and putting the optical disc 24 in the optical disc read-write drive 8 back into the optical disc case 1 In the automatic operation process, the specific operation steps are as follows:

[0053] 1) The control system 9 issues instructions, and the input and output device 6 transports the disc cartridge 1 from the original position to the position to be operated;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com