Ldmos tube with lateral concentration gradient in drift region and manufacturing method thereof

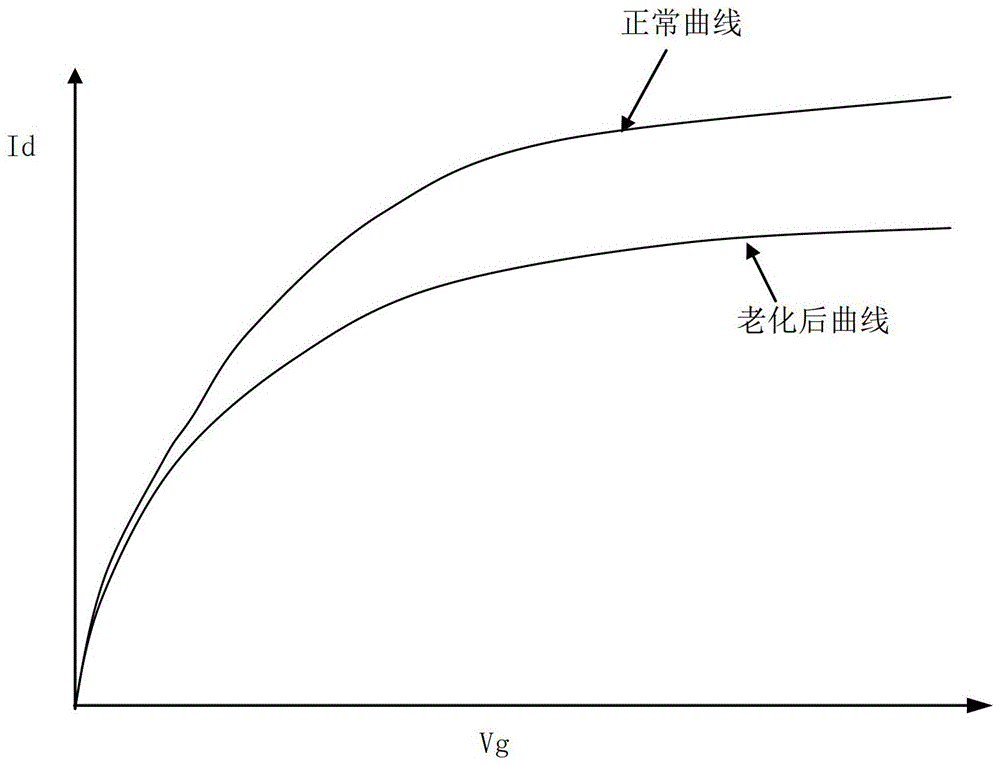

A concentration gradient and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of reduced drift region resistance, drift region energy band influence, linear current increase, etc. Hot carrier effect, effect of reducing voltage difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

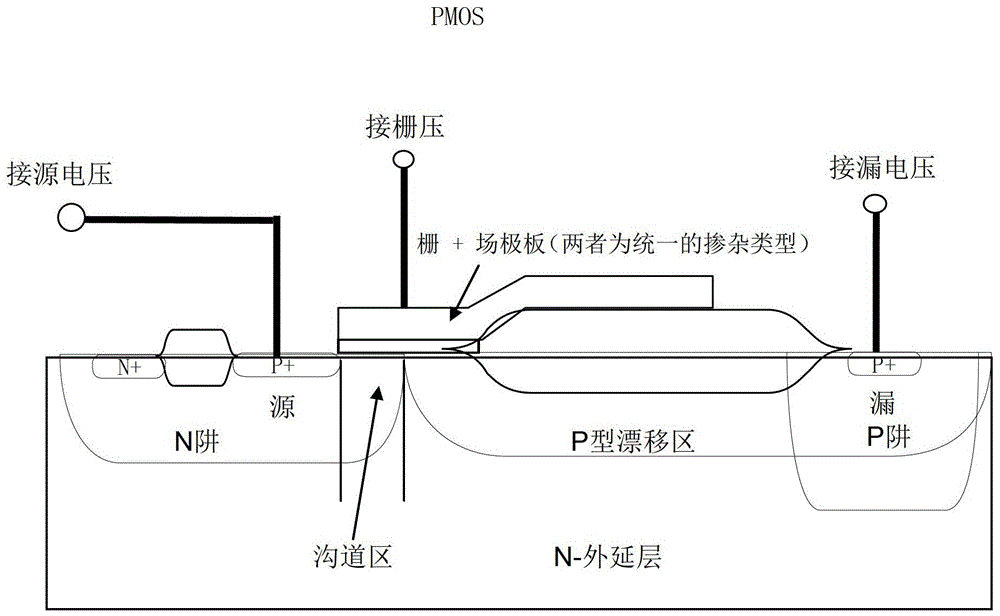

[0018] In order to have a more specific understanding of the technical content, characteristics and effects of the present invention, the PLDMOS tube is now taken as an example, and in combination with the illustrated embodiment, the LDMOS tube of the present invention and its manufacturing method are described in detail as follows:

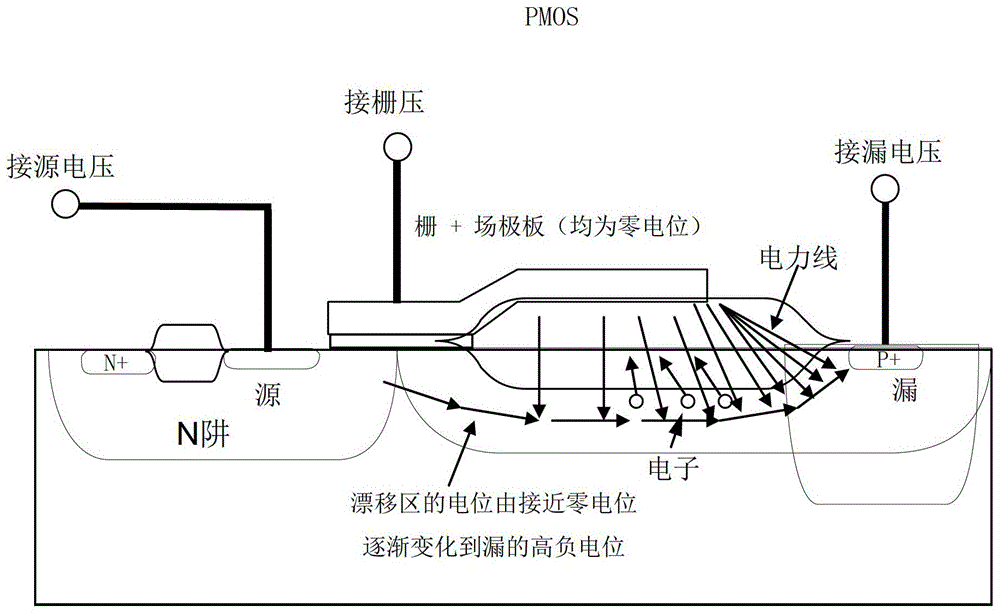

[0019] Such as Figure 4 As shown, the gate and field plate of the PLDMOS transistor in this embodiment are composed of continuous polysilicon (poly); the gate is N-type heavily doped and connected to the gate; the field plate is divided into P-type polysilicon field plates ( Depletion region) and N-type polysilicon field plate (connection region), the size of the two parts can be flexibly adjusted according to actual needs. Among them, the doping type of the P-type polysilicon field plate is opposite to that of the gate, which is P-type lightly doped; the P-type polysilicon field plate is connected to the gate and forms a PN junction with the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com