Manufacturing process of mosquito-dispelling floor mat

A preparation process and a technology for repelling mosquitoes, which are applied to carpets, pest repellents, animal repellents, etc., can solve the problems of unsatisfactory insect-proofing effect of carpets, unsuitable for popularization and use, etc., so as to improve the mosquito repellent rate and increase the number of mosquitoes The effect of repelling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

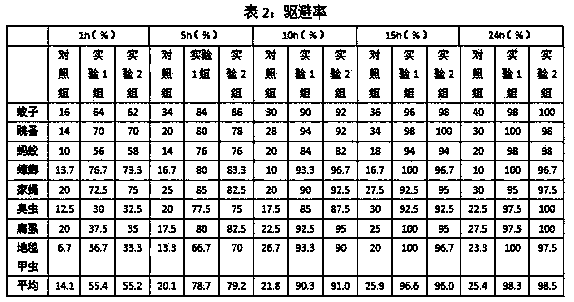

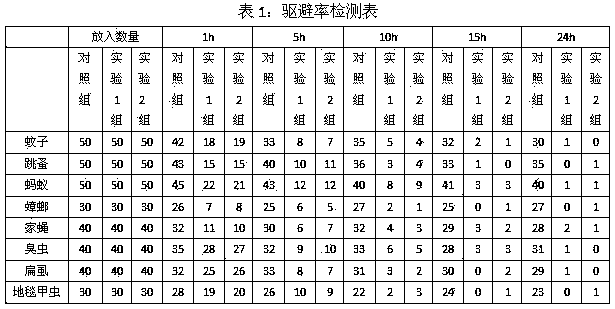

Examples

Embodiment 1

[0023] 100% nylon printed carpet, weight 1000g / ㎡, the preparation process of the mosquito repellent carpet is as follows:

[0024] Inkjet printing: the vehicle speed is 1.7m / mim;

[0025] Color fixation: the temperature of the steamer is 128°C;

[0026] Washing: water temperature 35°C;

[0027] Pressure roller pressure: 2Pa;

[0028] Vacuum pump pressure: 3Pa;

[0029] Oven temperature: the temperature of the first and second sections is 80°C, the temperature of the third and fourth sections is 130°C;

[0030] The mosquito repellent solution used in the foaming device includes:

[0031] Insect repellant SPA 80g / L

[0032] Foaming agent SBL 5g / L

[0033] Enhancer Nano PU 100g / L

[0034] The foam application process is as follows: first, use a foaming device to foam, prepare a solution, and use citric acid to adjust the pH to 5, set the liquid-vapor ratio to 1:40, and produce a foam quality of 25g / L, and then apply the foam through the foaming device. Foam, spread evenly...

Embodiment 2

[0037] 50% wool 50% nylon blended printed carpet, weight 1000g / ㎡, the preparation process of the mosquito repellent carpet is as follows:

[0038] Inkjet printing: the speed is 1.5m / mim;

[0039] Color fixation: the temperature of the steamer is 128°C;

[0040] Washing: water temperature 35°C;

[0041] Pressure roller pressure: 2.5Pa;

[0042] Vacuum pump pressure: 4Pa;

[0043] Oven temperature: the temperature of the first and second sections is 100°C, the temperature of the third and fourth sections is 130°C;

[0044] The mosquito repellent solution used in the foaming device includes:

[0045] Insect repellant SPA 50g / L

[0046] Foaming agent SBL 5g / L

[0047] Enhancer Nano PU 100g / L

[0048] The foam application process is as follows: first, use a foaming device to foam, prepare a solution, and use citric acid to adjust the pH to 5, set the liquid-vapor ratio to 1:40, and produce a foam quality of 25g / L, and then apply the foam through the foaming device. Foam, sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com