Directional Lubricating Device and Lubricating Method for Flat Cake in the Embossing Process of Coins and Medals

A directional lubrication and commemorative medallion technology, which is applied in the field of metal plastic forming process lubrication, can solve the problems of product surface quality impact, non-metallic dust pollution equipment, detection accuracy drop, etc., to reduce dust damage to the human body, reduce product quality risks, The effect of improving equipment reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

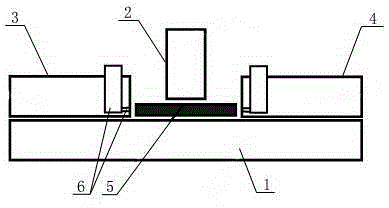

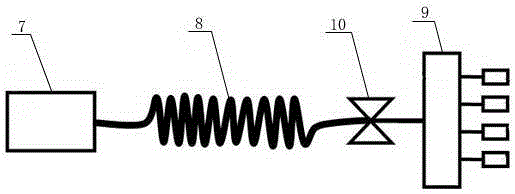

[0024] according to figure 2 Assemble the lubricant supply mechanism, in which the lubricating pump adopts the German Mock 475 electromechanical lubricator, the filling speed is 1.4ml / h, the outer diameter of the main pipe is 8mm, and the lubricant is Mobilgear XMP lubricating oil.

[0025] After testing, the above configuration can achieve directional lubrication in the coin imprinting process, and only apply lubricant to the cylindrical surface of the blank cake. After demoulding, the cylindrical surface of the coin product is smooth, and the surface brightness of the product is significantly better than the traditional grease block stirring lubrication method. , At the same time, the cleanliness of the product is high, there is no obvious dust in the imprinting equipment, and the dust on the surface of the optical device in the follow-up equipment is obviously less.

specific Embodiment example 2

[0027] according to figure 2 Assemble the lubricant supply mechanism, in which the lubricating pump is a medical syringe pump, the specific model is TCI-11, the filling speed is 2.0ml / h, the outer diameter of the main pipe is 6mm, and the lubricant is M0053 lubricating oil.

[0028] After testing, the above configuration can achieve directional lubrication in the coin imprinting process. Only the lubricant is applied to the cylindrical surface of the blank cake, and the cylindrical surface of the coin product is smooth after demoulding. The surface brightness of the product is significantly better than that of the traditional grease block stirring and lubrication method. At the same time, the product is clean and there is no obvious dust in the imprinting equipment, and the dust on the surface of the optical device in the follow-up equipment is obviously less.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com