Device for pressing and combining inner bottle cap and outer bottle cap

An outer cover and cover pressing technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that the inner cover and the outer cover are not pressed tightly into each other, and the completion efficiency is not very high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

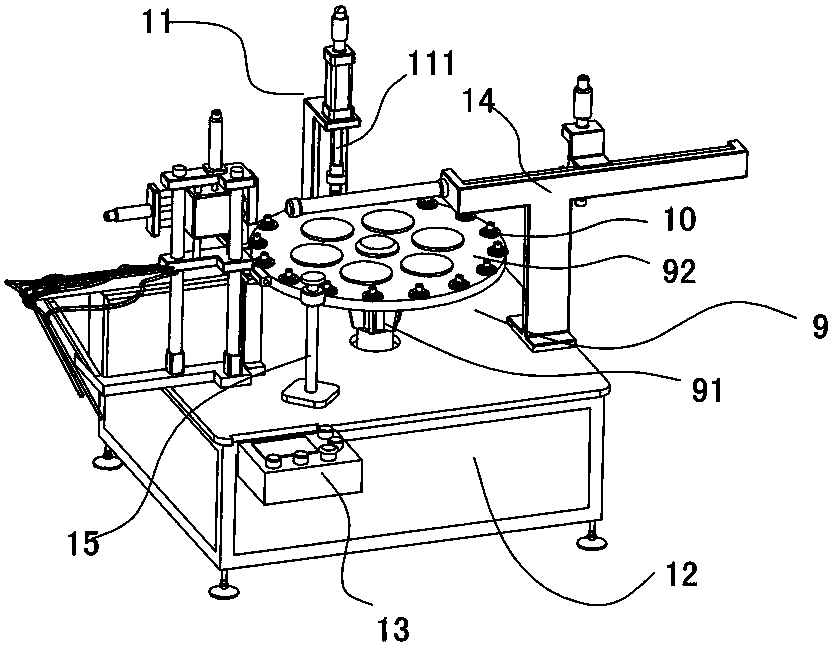

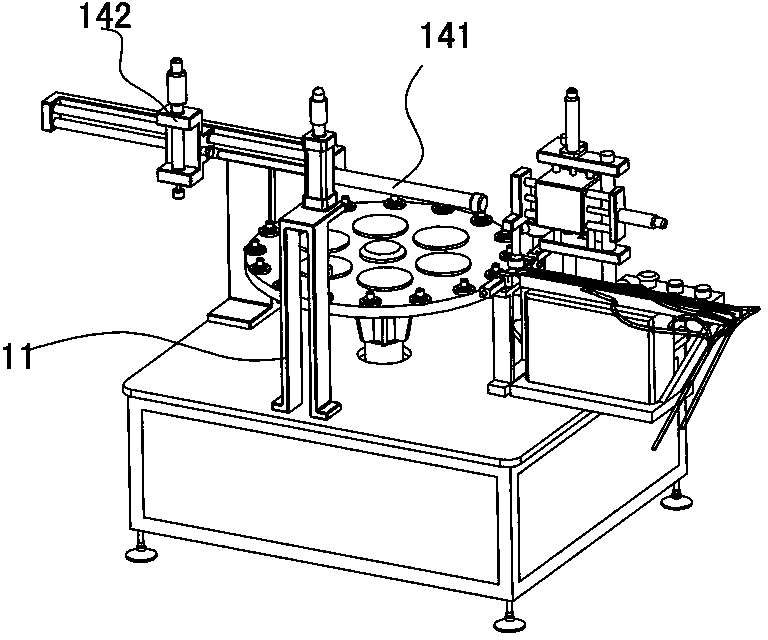

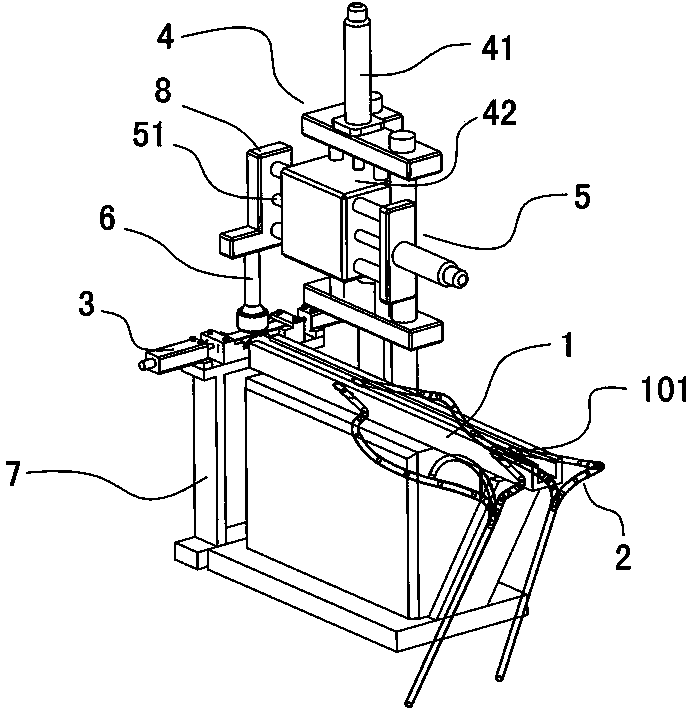

[0014] Please refer to Figure 1 to Figure 2 , the bottle inner and outer cap pressing device in the figure includes a bottle outer cap inserting mechanism, a rotary table 9, a bottle inner cap mounting seat 10, a pressing cylinder 11, a base 12, a cylinder driving mechanism 13, A horizontal motion cylinder 14, a bottle inner cap infrared detection head 15; its pressing action is to place the bottle inner cap, detect whether the bottle inner cap is placed, place the bottle outer cap on the bottle inner cap, press the bottle outer cap Put the cap on the bottle and put the pressed cap on the cap conveying line.

[0015] The bottle inner cap is placed on the bottle inner cap mounting seat 10 and generally uses a manual method, and the workman's working position is between the horizontal motion cylinder 14 and the bottle inner cap infrared detection head 15 . Please refer to figure 1 , figure 2 , Image 6 , the bottle inner cap mounts 10 in the figure are all over the edge po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com