Anti-freezing packaging box for cold storage drugs and anti-freezing packaging method for drug transportation process

A technology of transportation process and packaging method, applied in the field of pharmaceutical packaging, can solve the problems of slow delivery speed, complicated operation process, waste of labor, etc., and achieve the effect of saving the time of returning to temperature, shortening the operation time and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

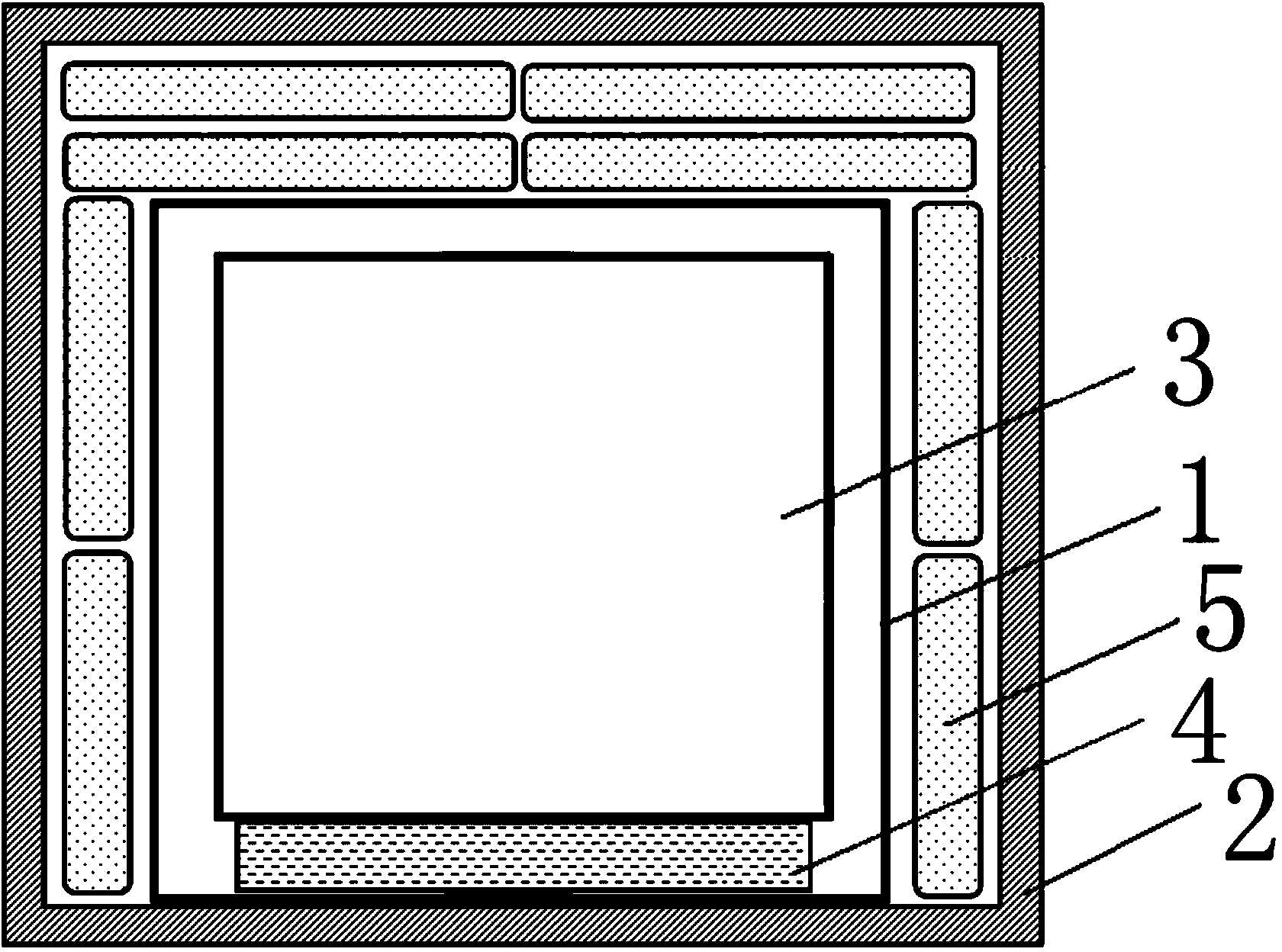

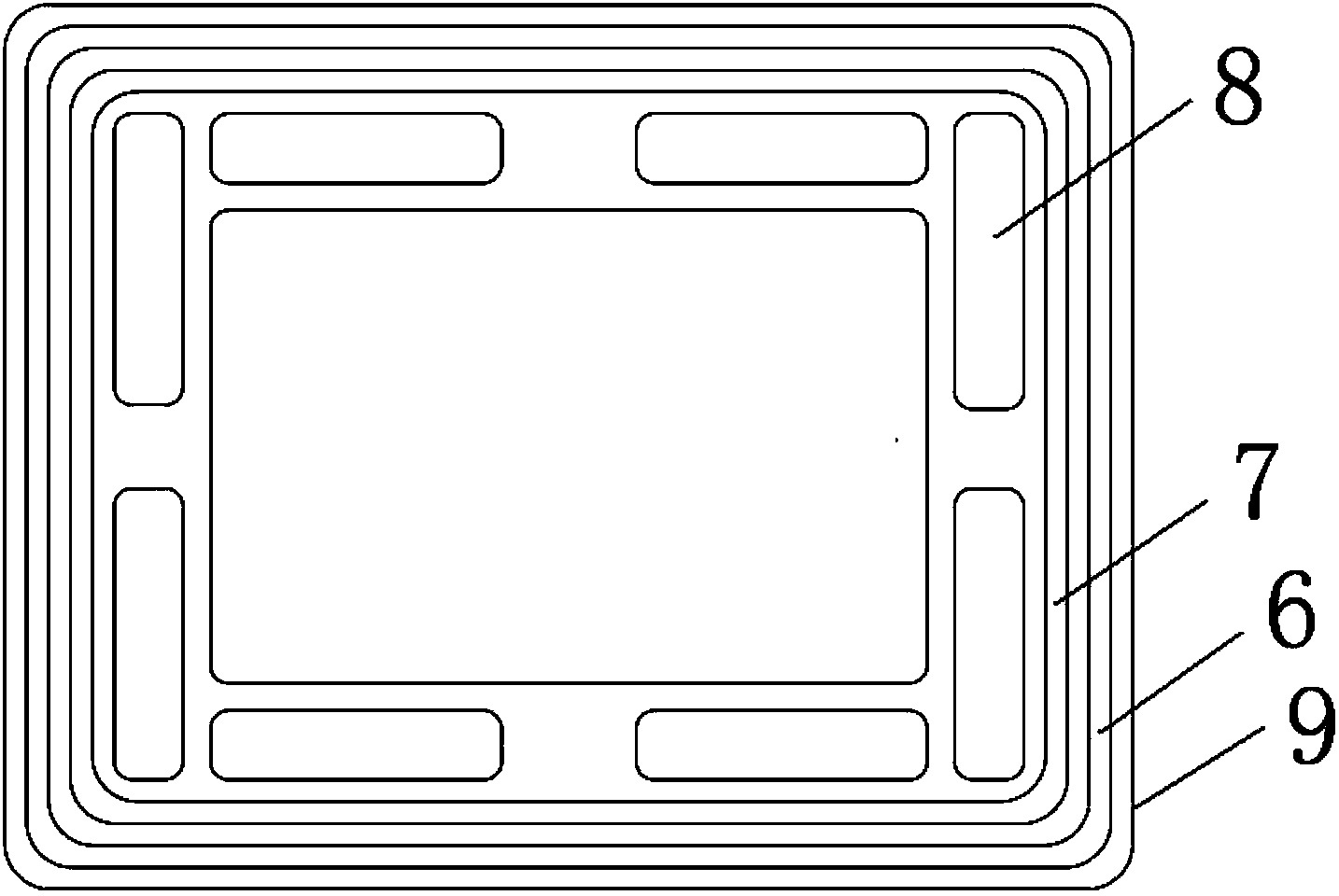

[0031] see figure 1 and figure 2 , the antifreeze packaging box for medicine 3 of the present embodiment includes an outer packaging box 2 and an inner insulated box 1 placed in the outer box 2, the inner insulated box 1 is provided with a medicine 3 to be kept warm and a warm ice module 4, and the outer packaging box An ice bag 5 is arranged between the box 2 and the inner heat preservation box 1; the ice warming module 4 includes a shell and liquid organic substances with a melting point of 5-10°C contained in the shell.

[0032] When the above-mentioned refrigerated medicine antifreeze packing box is used, since the inner insulated box 1 is arranged in the outer packing box 2, when the temperature of the ice pack 5 is far lower than 2°C, it can effectively prevent the cold energy of the ice pack 5 from being transferred to the medicine box. In the medicine 3, in addition, when the temperature in the inner incubator 1 is lower than 5°C, the warm ice will undergo a phase ch...

Embodiment 2

[0044] The antifreeze packaging method in the medicine transportation process of the present invention comprises the following steps:

[0045] S102, taking the medicine box containing the medicine out of the refrigerator and putting it into the inner incubator;

[0046] S202. Place an ice warming module filled with warm ice in the inner incubator, and the warm ice is a liquid organic substance with a melting point of 5-10°C;

[0047] S302, sealing the inner insulation box and putting it into the outer packing box;

[0048] S402, directly fixing the frozen ice bag taken out of the freezing device in summer between the inner insulation box and the outer packing box;

[0049] S502. Seal the outer packing box.

[0050] The antifreeze packaging method in the medicine transportation process of this embodiment is suitable for the transportation of medicines in summer, because the medicine box and the warm ice module are placed in the inner insulation box together, and then placed i...

Embodiment 3

[0056] The antifreeze packaging method in the medicine transportation process of the present embodiment comprises the following steps:

[0057] S103, taking the medicine box containing the medicine out of the refrigerator and putting it into the inner incubator;

[0058] S203. Place an ice warming module filled with warm ice in the inner incubator, and the warm ice is a liquid organic matter with a melting point of 5-10°C;

[0059] S303. Put the inner insulation box into the outer packing box after sealing;

[0060] S403. Directly fix the non-freezing ice pack in winter between the inner insulation box and the outer packing box;

[0061] S503. Seal the outer packing box.

[0062] The antifreeze packaging method in the drug transportation process of this embodiment is suitable for the transportation of drugs in winter. In winter, if the packaging in this embodiment is used, if the external temperature is too low and the temperature of the ice bag is too low, it can effectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com