One-step method for synthesizing copper-containing CHA type molecular sieve with high hydro-thermal stability

A thermally stable, molecular sieve technology, applied in the direction of molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problems of low utilization rate of metal ions, decreased molecular sieve stability, long synthesis time, etc., and shorten the preparation time. effect of time, high crystallinity and specific surface area, simplified operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) First stir pseudo-boehmite fully in deionized water, then slowly add phosphoric acid to completely peptize pseudo-boehmite; after peptization is complete, add fumed silica and copper acetate and stir evenly, then add four Ethylammonium hydroxide and diethylenetriamine are stirred vigorously; the molar ratio P of each reaction raw material in the molecular sieve synthesis liquid 2 o 5 :Al 2 o 3 :SiO2 2 :T:L:CuO:H 2 O is 0.9:1.0:0.5:2.0:0.2:0.05:80, where T is tetraethylammonium hydroxide, L is diethylenetriamine, and after stirring for 4 hours, put it into tetrafluoroethylene or p-polystyrene In a lined stainless steel reactor; crystallize this reactor at 160°C for 5 days;

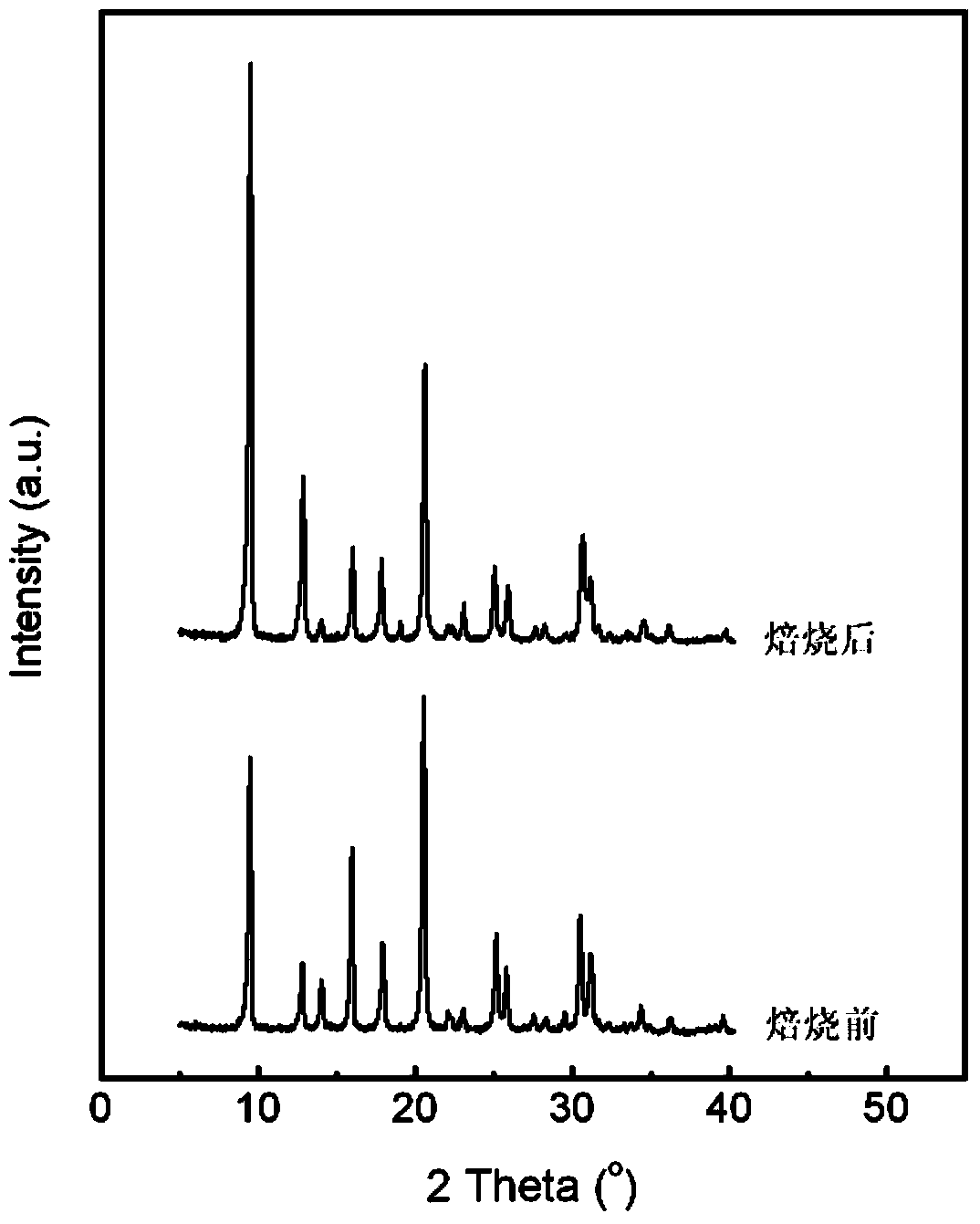

[0019] (2) After the crystallization is completed, the obtained product is suction-filtered, washed several times with deionized water until the washing liquid is neutral, and the obtained solid product is dried in an oven at 80°C for 6 hours; then the dried product is dried in a muffle furn...

Embodiment 2

[0025] (1) First, fully stir the pseudo-boehmite in deionized water, then slowly add phosphoric acid to completely peptize the pseudo-boehmite; after the peptization is complete, add fumed silica and copper acetate and stir evenly, then add three Ethylamine and diethylenetriamine are stirred vigorously; the molar ratio P of each reaction raw material in the molecular sieve synthesis liquid 2 o 5 :Al 2 o 3 :SiO2 2:T:L:CuO:H 2 O is 0.9:1.0:0.5:3.0:0.3:0.1:80, where T is triethylamine and L is diethylenetriamine; after stirring for 4 hours, put it into stainless steel lined with tetrafluoroethylene or p-polystyrene In the reactor; crystallize the reactor at 200°C for 3 days;

[0026] (2) After the crystallization is completed, the obtained product is centrifuged and washed several times until the washing liquid is neutral, and the obtained solid product is dried in an oven at 80°C for 6 hours; then the dried product is placed in a muffle furnace under an air atmosphere to T...

Embodiment 3

[0029] (1) First, fully stir the aluminum sol in deionized water, then slowly add phosphoric acid to dissolve the aluminum sol; after the dissolution is complete, add silica sol and copper chloride with a mass fraction of 40% and stir evenly, then add triethylamine and diethylenetriamine and vigorously stirred; the molar ratio P of each reaction raw material in the molecular sieve synthesis liquid 2 o 5 :Al 2 o 3 :SiO2 2 :T:L:CuO:H 2 O is 0.8:1.0:0.5:2.5:0.1:0.1:80, where T is triethylamine and L is diethylenetriamine; after stirring for 8 hours, put it into stainless steel lined with tetrafluoroethylene or p-polystyrene In the reactor; crystallize the reactor at 190°C for 5 days;

[0030] (2) After the crystallization is completed, the obtained product is filtered by plate and frame, and washed several times with deionized water until the washing liquid is neutral, and the obtained solid product is dried in an oven at 80°C for 6 hours; then the dried product is dried at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap