Nickel-base superalloy with high crack extension resistance

A high-temperature alloy and crack propagation technology, which is applied in the field of nickel-based powder metallurgy superalloys, can solve problems affecting the application of alloys, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

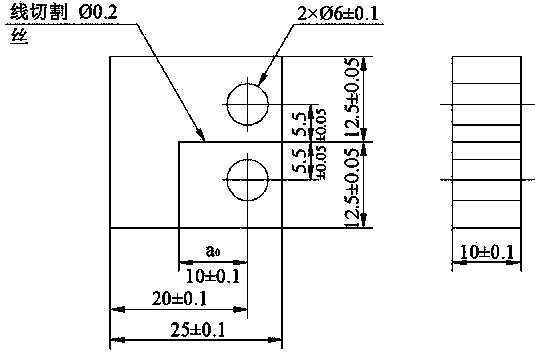

Image

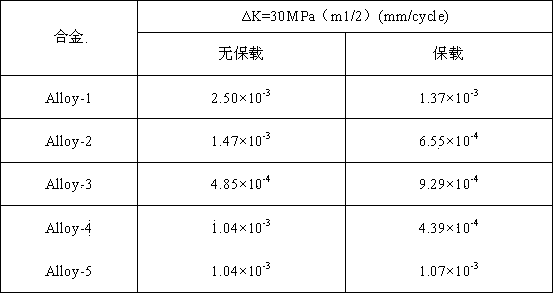

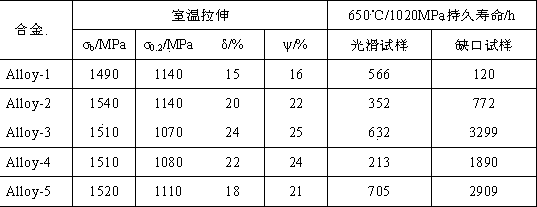

Examples

Embodiment Construction

[0011] The present invention will be further described below by specific examples.

[0012] (1) The content of nickel-based powder metallurgy superalloy Alloy-1 by mass percentage is: Co19.8%, Cr12.0%, W5.6%, Mo3.9%, Al5.1%, Ti1.8%, Nb2. 6%, C0.04%, B0.012%, Zr0.015%, Hf0.15~0.9%, the balance is Ni.

[0013] It is powdered by a plasma rotating electrode, and the powder particle size ranges from 50 to 150 μm. After hot isostatic pressing, it is then subjected to solution heat treatment, and the cold-rolled alloy plate is subjected to solution heat treatment in a box-type resistance furnace. The temperature is 870°C, the holding time is 2.9h, water quenching; aging heat treatment: divided into the following five steps: the aging temperature is 330°C, the holding time is 19min, water quenching; and then heated to 420°C for the second aging treatment, aging The time is 1.9h, water quenching; then heated to 485°C for the third aging, the aging time is 2h, water quenching; then hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com