Thin copper baffle bracket for vertical PCB (printed circuit board) plating line

A vertical electroplating, plate support technology, applied in the electrolysis process, electrolysis components and other directions, can solve the problems of manpower, material and financial resources, large price loss, work-related accidents when grinding cloaks, etc., and achieve the effect of reducing the number of maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

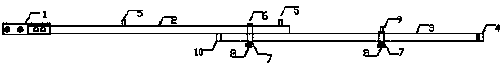

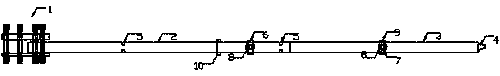

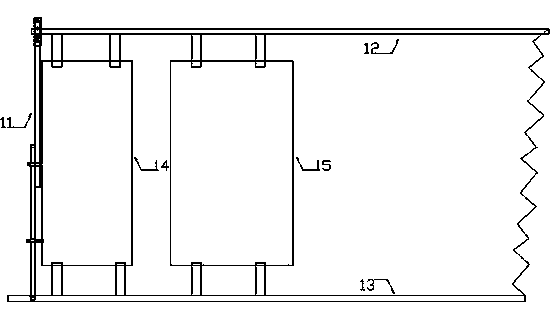

[0018] Such as Figure 1 to Figure 6 As shown, a PCB vertical electroplating line thin copper baffle bracket includes a flybar bracket 1, an upper telescopic column 2, a lower telescopic column 3, a lower telescopic column embedded block 4, an upper telescopic column embedded groove 5, a fixed annular ring 6, Nut 7, screw 8, adjustable annular ring embedding groove 9, stop edge 10, it is characterized in that one end of upper telescopic column 2 adopts screw and two flying bar supports 1 to fix, adopts fixed annular ring 6 to upper telescopic column 2 and The lower telescopic column 3 is set together and fixedly connected, the lower telescopic column 3 is set with an adjustable annular ring embedding groove 9, the upper telescopic column 2 is provided with an upper telescopic column embedding groove 5, and the other end of the lower telescopic column 3 is provided with There is a telescoping post embedded block 4; the fixed annular ring 6 is composed of an annular ring, a nut ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com