Organosilicon synthetic leather adopting three-layer structure and preparation method thereof

A technology of organosilicon synthetic leather and three-layer structure, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, lamination, etc., and can solve problems such as easy to absorb dust, poor scratch resistance, and large surface friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

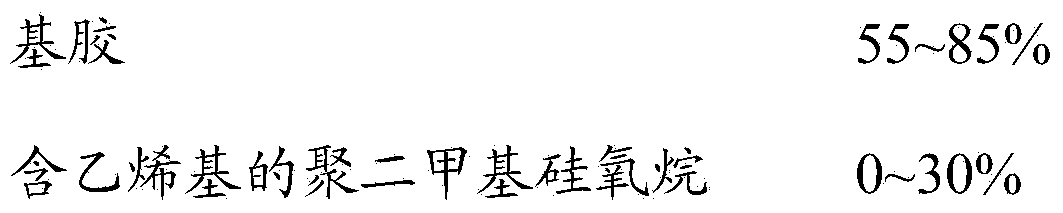

[0067] The organosilicon synthetic leather of the three-layer structure of the present embodiment is formed by sequentially bonding the base material, the bottom layer glue and the surface layer glue; the bottom layer glue includes the following components in mass percentage:

[0068]

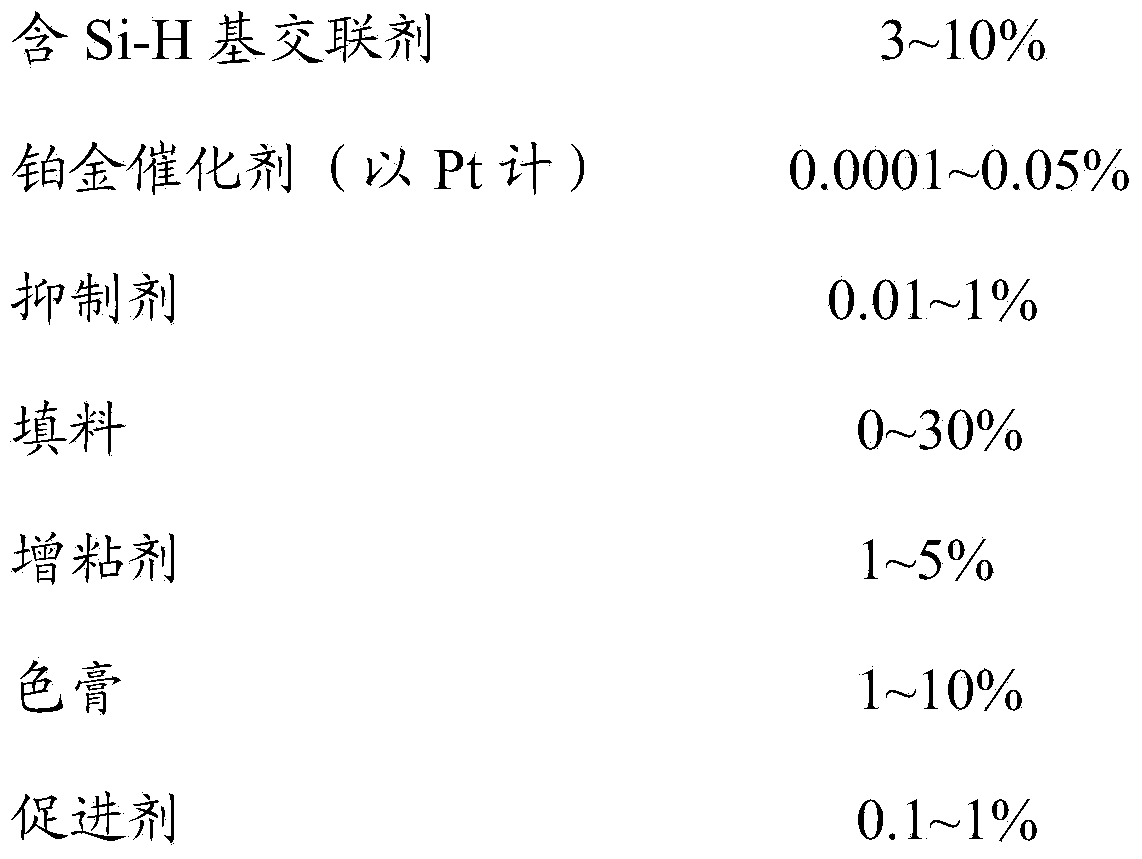

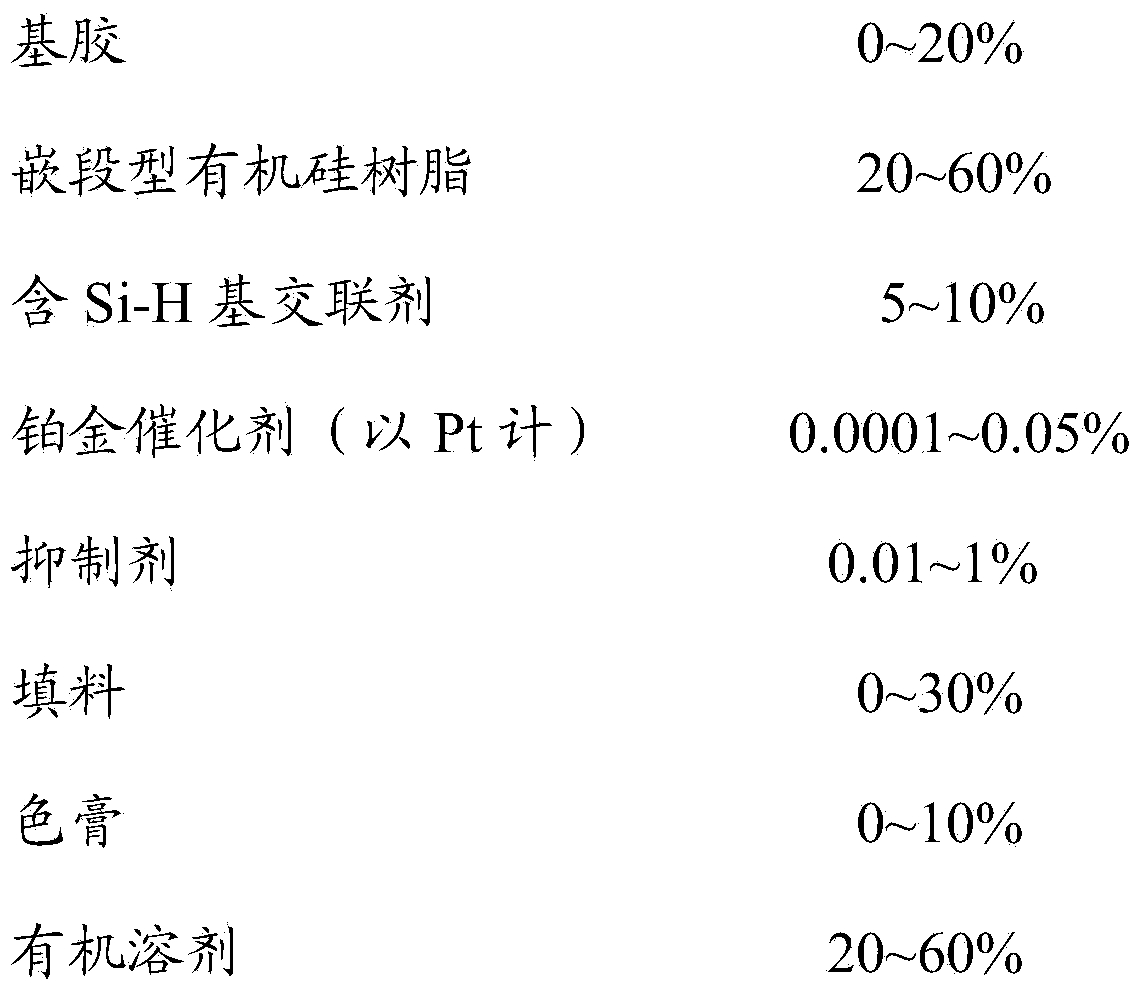

[0069] The surface layer glue includes the following components in mass percentage:

[0070]

[0071]

[0072] In the above-mentioned bottom layer adhesive and surface layer adhesive, polydimethylsiloxane containing 3 hydrogen atoms of Si-H-based cross-linking agent directly connected to Si, the hydrogen atoms are located in the side chain, the content of hydrogen atoms is 0.5%, and the cross-linking The agent is linear;

[0073] In the above-mentioned primer and surface glue, the platinum catalyst is a chloroplatinic acid-divinyltetramethyldisiloxane complex, and the content of Pt atoms is 2000ppm;

[0074] Among the above surface glues, R 3 SiX Links and SiX 4 The molar ratio of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com