A kind of preparation method of sealing strip

A technology of sealing strips and sealing rings, applied in sealing devices and other directions, can solve the problems of poor cold resistance, elasticity and aging performance, surface pollution of plastic steel doors and windows, complicated processing technology, etc., and achieve excellent high and low temperature resistance and uniform appearance quality. , the effect of feeling good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

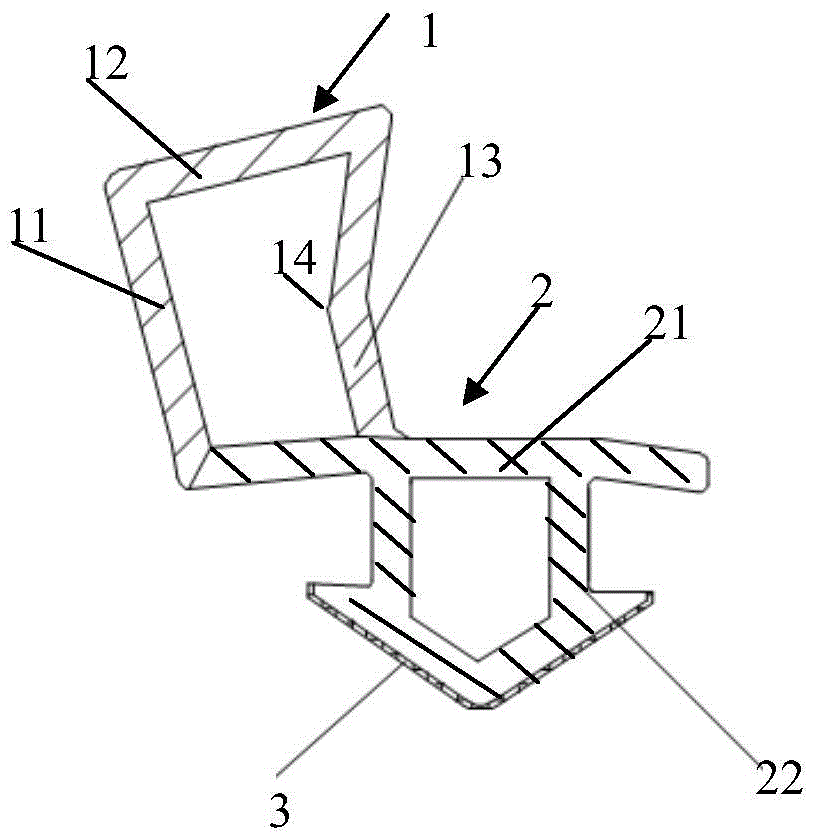

[0033] The preparation method of sealing strip of the present invention comprises the following steps,

[0034] 1) According to the material and volume of the sealing ring, snap-in body and reinforcing layer, the raw materials are granulated respectively;

[0035] 2) Put the prepared pellets into the corresponding co-extrusion machine and simultaneously extrude them according to the amount into the mold according to the soft and hard co-extrusion process and shape them with the help of the mold;

[0036] 3) Pull the extruded rubber strip to the cooling water tank through the tractor, and coil and pack it after cooling.

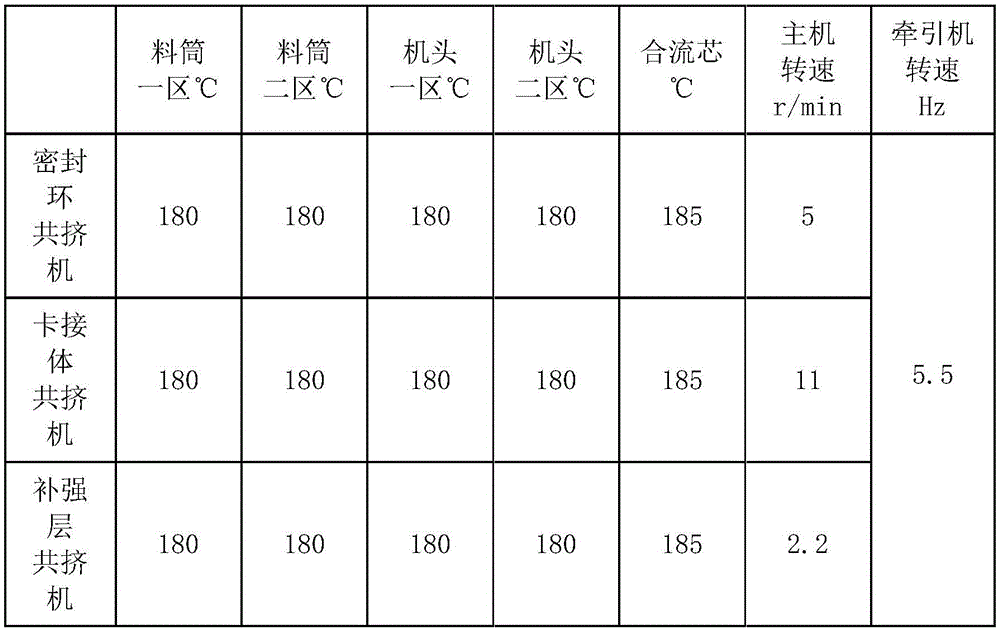

[0037] Among them, during co-extrusion, parameters such as the temperature of each co-extrusion machine and the speed of the host machine can be routinely set according to the size of the extruded rubber strip.

[0038] Such as extrusion equipment can use 35 single-screw extruder, the specific parameters are shown in Table 1

[0039] Table 1

[0040]

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com