Internal-pressure self-control ball valve

A ball valve and internal pressure technology, which is applied to the valve details, valve device, valve shell structure, etc., can solve the problems of accelerating the wear of seals, affecting the service life of the ball valve, and large opening and closing torque, so as to achieve reliable sealing, long service life, The effect of reducing moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

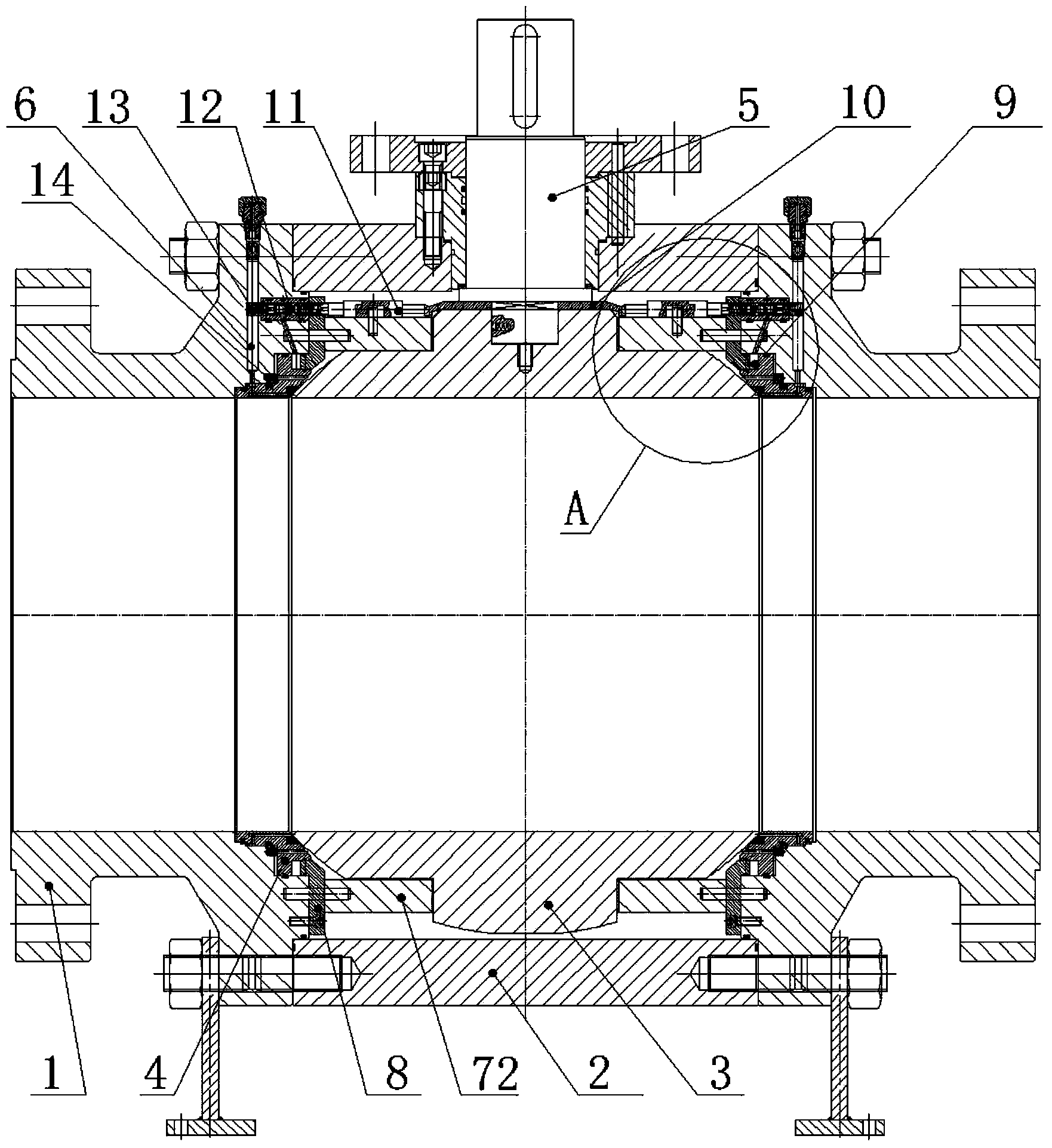

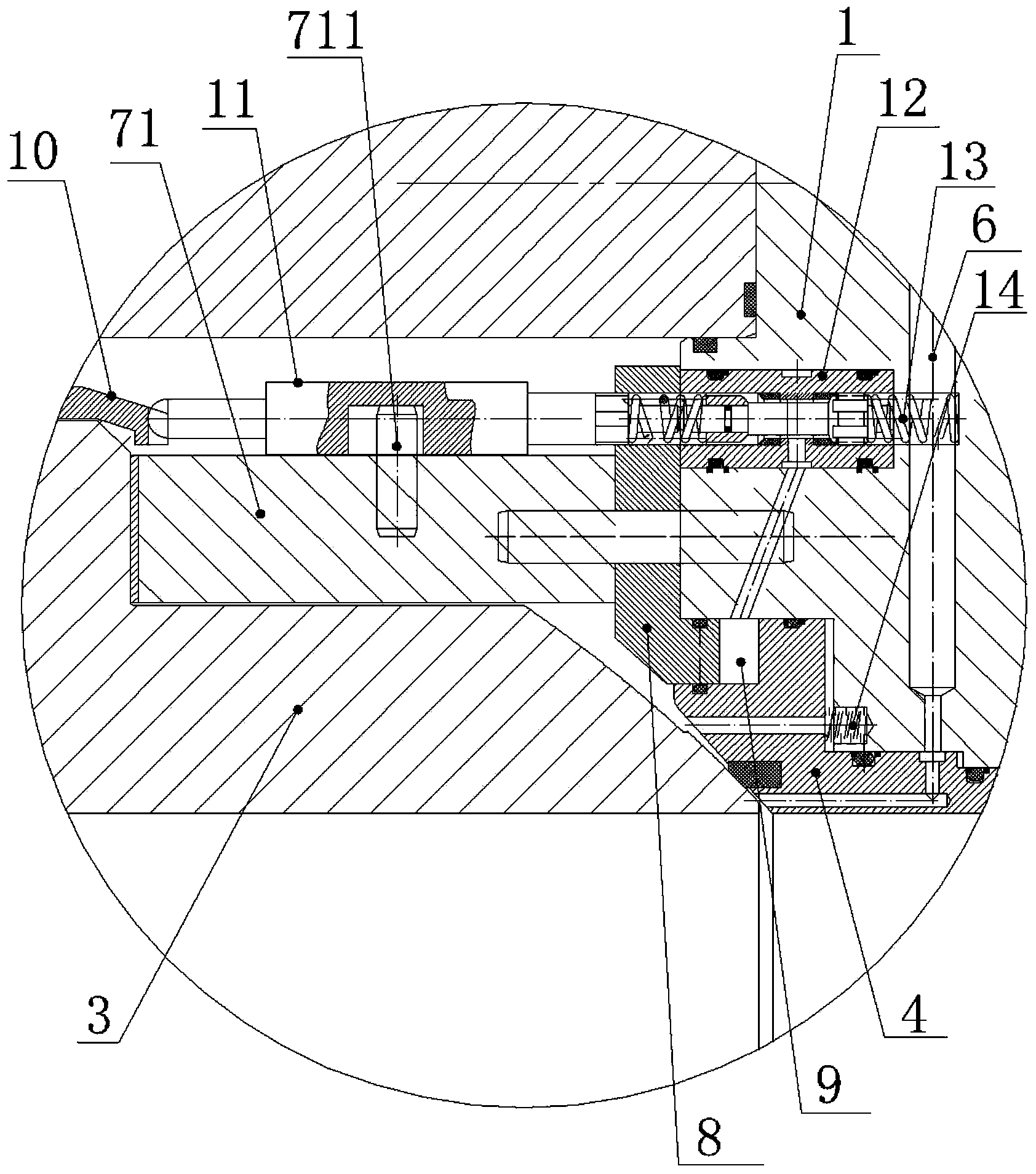

[0023] Embodiment: a kind of internal pressure self-control ball valve, such as figure 1 As shown, it includes a side valve body 1, a middle valve body 2, a ball 3, a valve seat 4 and a valve stem 5. The ball is arranged in the cavity formed by the side valve body and the middle valve body. Adjacent to the side valve body, the valve stem passes through the middle valve body and its lower end is inserted into the ball.

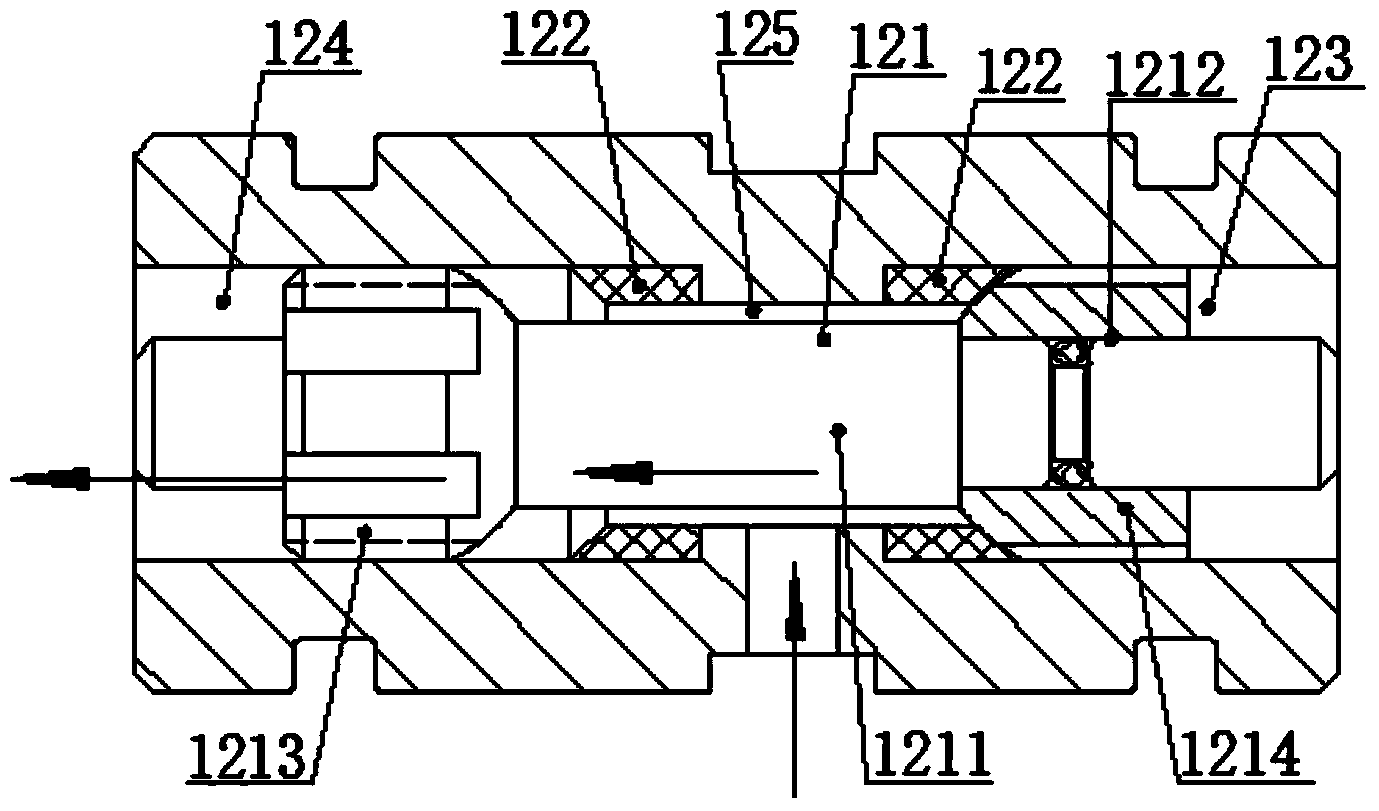

[0024] combine figure 1 and figure 2 , the side valve body 1 is drilled with a flow passage 6 through which medium pressure can pass, and the valve seat 4 is an elastic valve seat with a valve seat spring 14 between the side valve body and the valve seat. The upper and lower ends of the sphere are respectively provided with upper and lower support plates 71, 72, the upper and lower support plates have middle holes, the sphere has an intermediate shaft, the middle holes of the upper and lower support plates are connected to the The intermediate shafts of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap