Method for preparing local enhancement aluminum matrix composite

An aluminum-based composite material and local reinforcement technology, applied in the field of metal-based composite material preparation, can solve the problems of low carbon content, long reaction time, complicated device, etc., and achieve the effects of good filling, rapid response and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

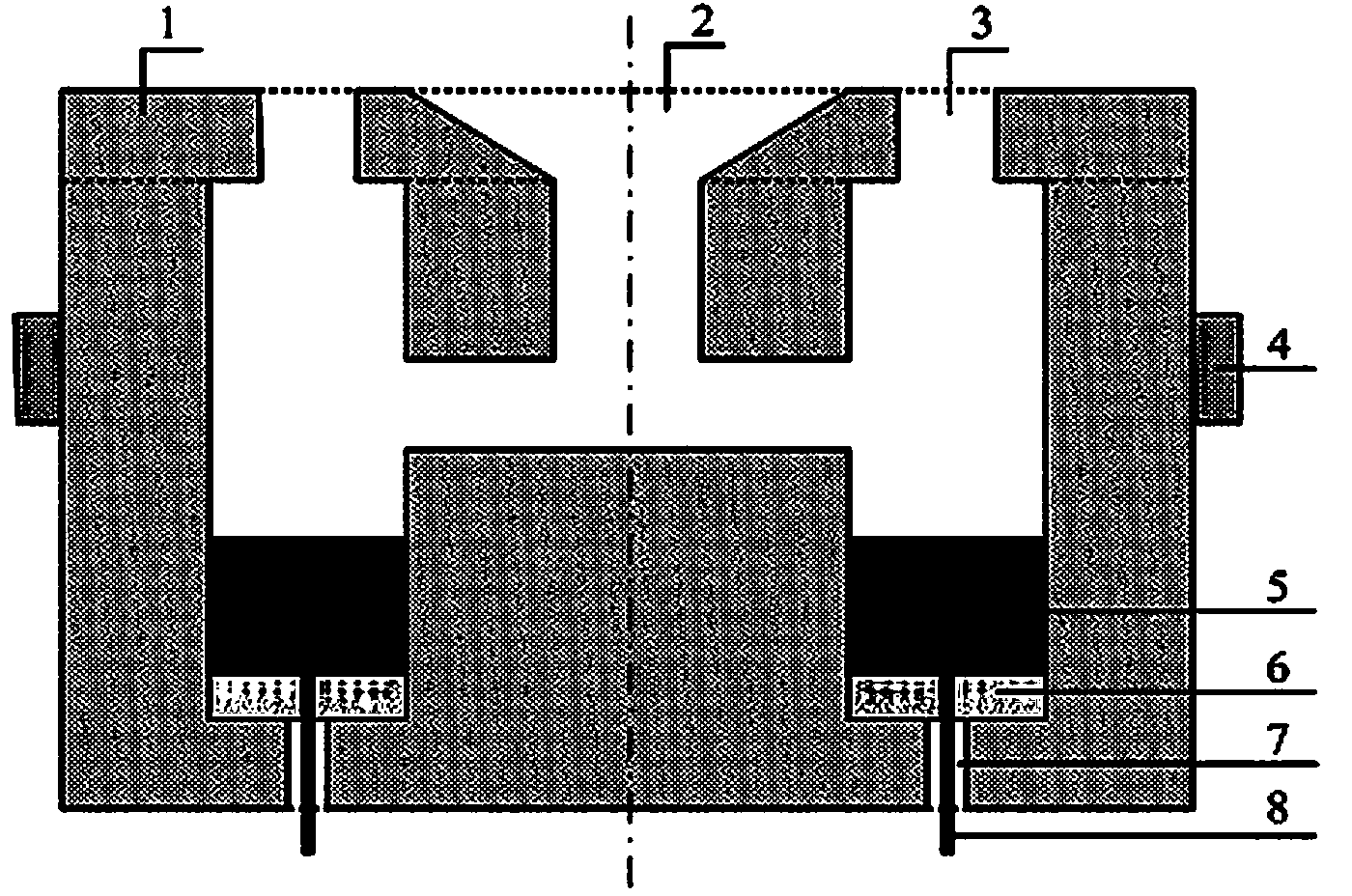

Image

Examples

Embodiment 1

[0023] The method for preparing locally reinforced aluminum-based composite materials described in this embodiment uses Al powder, Ti powder, graphite powder and pure Al blocks as raw materials, and includes the following steps:

[0024] 1. Al powder, Ti powder, and graphite powder are formulated into Al-Ti-C mixed powder; in the Al-Ti-C mixed powder, the weight percent content of Al powder is 20 wt.%, Ti powder+graphite powder The weight percentage content is 80 wt.%, and the molar ratio of Ti powder and graphite powder is 1; Wherein: the purity of described Ti powder is 98%, and average particle size is 40 μ m; The purity >=99.9% of described graphite powder, average particle size It is 30 μm; the purity of the Al powder > 99%, and the average particle size is 40 μm;

[0025] 2. Ball mill the Al-Ti-C mixed powder to make it evenly mixed; then, press the evenly mixed Al-Ti-C mixed powder into a diameter of 20 mm, a thickness of 15 mm, and a relative density of 65±3% Cylindri...

Embodiment 2

[0030] The method for preparing locally reinforced aluminum-based composite materials described in this embodiment uses Al powder, Ti powder, graphite powder and pure Al blocks as raw materials, and includes the following steps:

[0031] 1. Al powder, Ti powder, and graphite powder are formulated into Al-Ti-C mixed powder; in the Al-Ti-C mixed powder, the weight percent content of Al powder is 30 wt.%, Ti powder+graphite powder The weight percentage content is 70 wt.%, and the mol ratio of Ti powder and graphite powder is 1; Wherein: the purity of described Ti powder is 98%, and average particle size is 40 μ m; The purity >=99.9% of described graphite powder, average particle size It is 30 μm; the purity of the Al powder > 99%, and the average particle size is 40 μm;

[0032] 2. Ball mill the Al-Ti-C mixed powder to make it evenly mixed; then, press the evenly mixed Al-Ti-C mixed powder into a diameter of 20 mm, a thickness of 15 mm, and a relative density of 65±3% Cylindrica...

Embodiment 3

[0037] The method for preparing locally reinforced aluminum-based composite materials described in this embodiment uses Al powder, Ti powder, graphite powder and pure Al blocks as raw materials, and includes the following steps:

[0038] 1. Al powder, Ti powder, and graphite powder are formulated into Al-Ti-C mixed powder; in the Al-Ti-C mixed powder, the weight percent content of Al powder is 40 wt.%, Ti powder+graphite powder The weight percentage content is 60 wt.%, and the mol ratio of Ti powder and graphite powder is 1; Wherein: the purity of described Ti powder is 98%, and average particle size is 40 μm; The purity >=99.9% of described graphite powder, average particle size It is 30 μm; the purity of the Al powder > 99%, and the average particle size is 40 μm;

[0039] 2. Ball mill the Al-Ti-C mixed powder to make it evenly mixed; then, press the evenly mixed Al-Ti-C mixed powder into a diameter of 20 mm, a thickness of 15 mm, and a relative density of 65±3% Cylindrical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com