Caterpillar band guiding and derail preventing rail clamping device

A technology of crawler and rail clamp, which is applied in the directions of crawler vehicles, transportation and packaging, motor vehicles, etc., can solve the problems of insufficient shear strength, failure of rail clamps, and excessive clearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

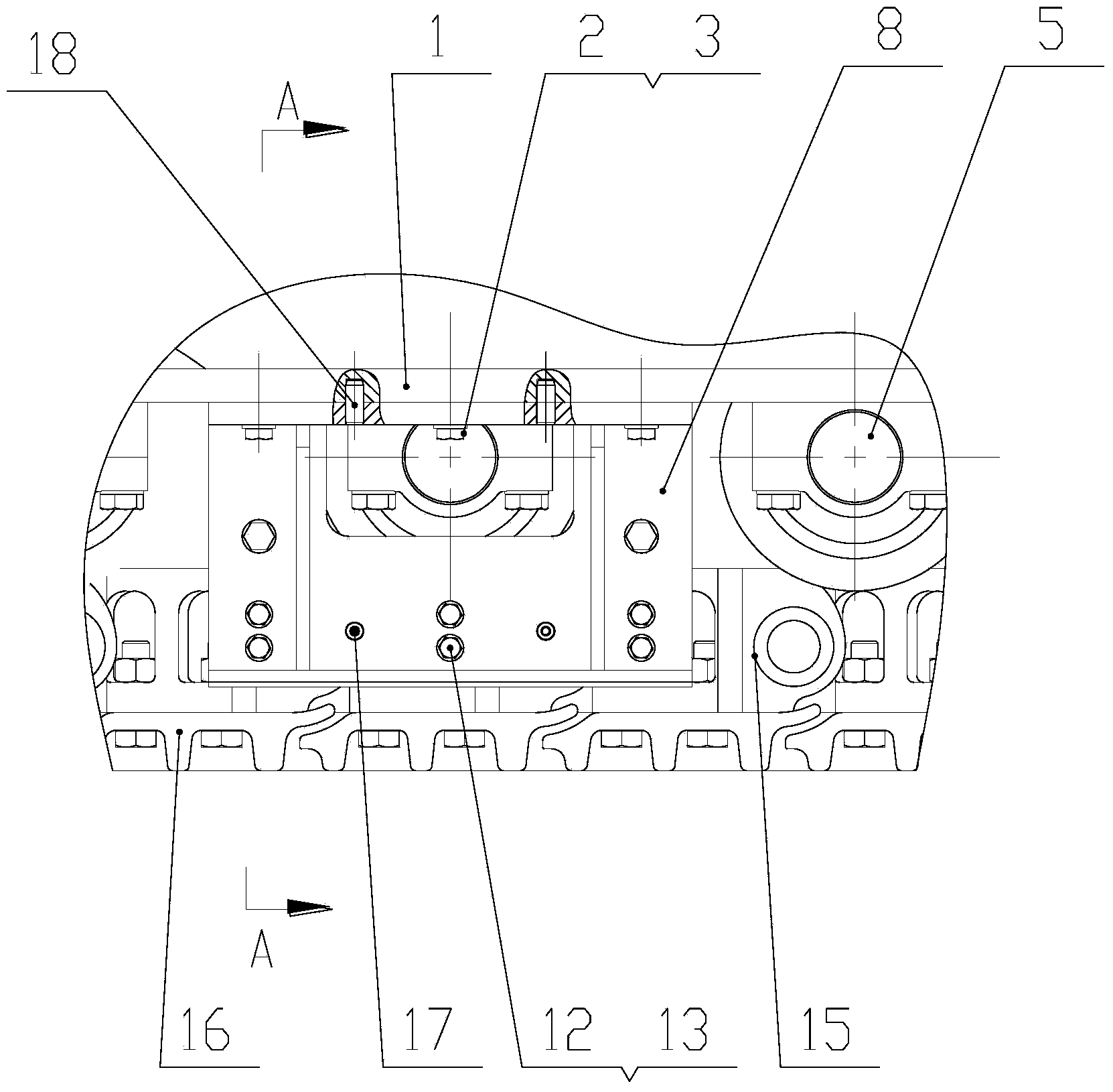

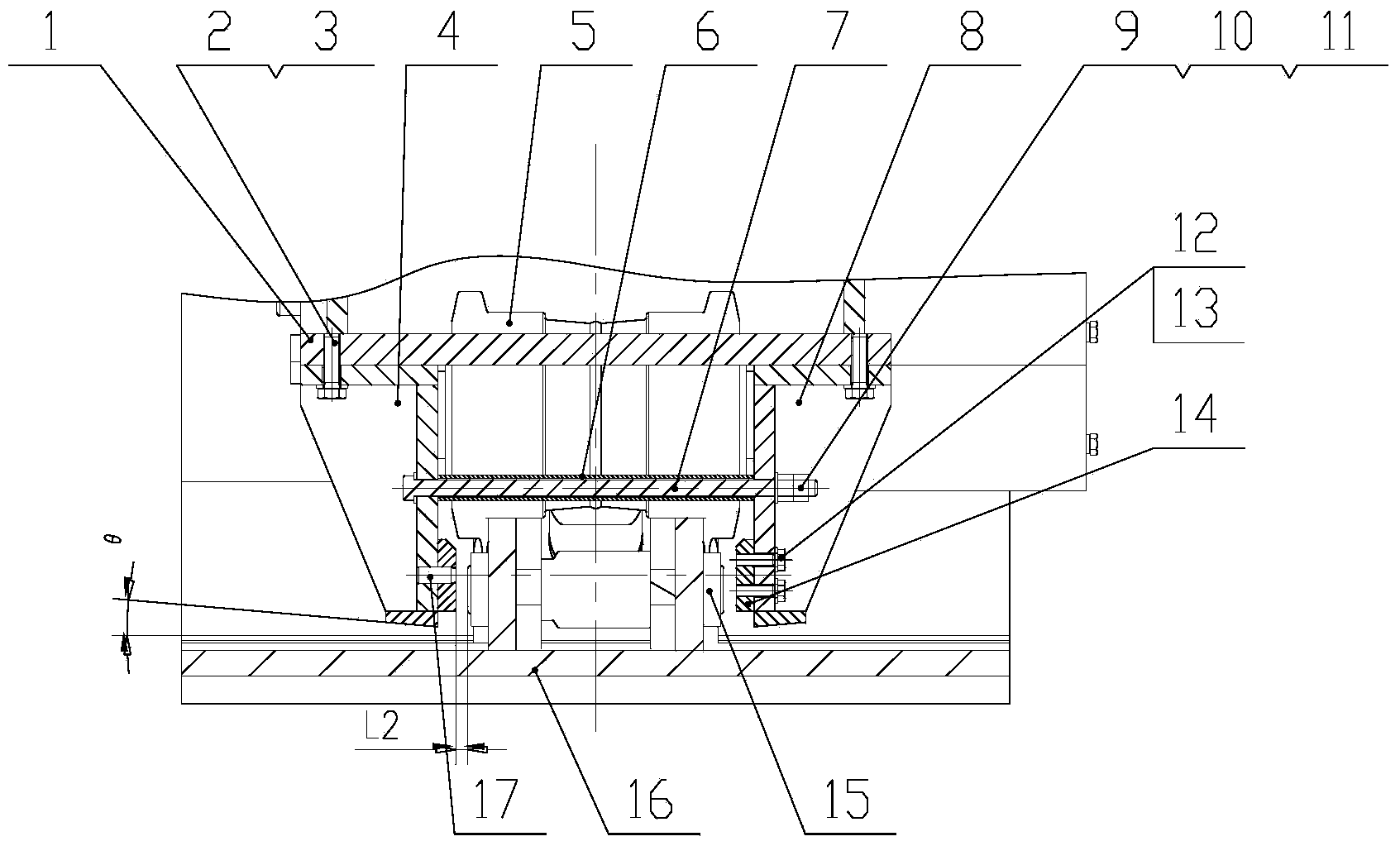

[0034] like Figure 1-3 As shown, the clamper of this embodiment is a rail clamping device for construction machinery chassis using a crawler walking device. It specifically relates to the connection between the bottom surface of the side beam 1 of the construction machinery chassis using crawler belts by connecting the first connecting bolt 2 and the first elastic washer 3, and symmetrical installation at the installation positions of multiple rail clamps on the bottom surface of the side beam 1 of the construction machinery chassis. The point rail clamps of the left rail clamp 4 and the right rail clamp 8 are located on both sides of the track roller 5 and the chain rail wheel of the crawler construction machinery. In order to ensure that the left rail clamp 4 and the right rail clamp 8 is subjected to external force and shears and destroys the connecting bolt 2, and a connecting positioning pin 18 is designed in the connection between the chassis side beam 1 and the left ra...

Embodiment 2

[0039] In order to eliminate the installation of many pairs of left rail clamps 4 and right rail clamps 8, the size of the clamping rail gap L2 is different, and there are errors. The overall structure of the half "I" character formed by the side plate, the length of the side plate, the upper plate and the lower plate is 70-90% of the ground length of the construction machinery chain rail, and there are multiple pairs of tie rods at intervals in the length direction of the side plate Holes, perpendicular to the side panels are provided with stiffeners near the holes of each tie rod. There is a circular arc transition between the upper plate and the lower plate. The rail clamp of the present embodiment is a surface rail clamp of the above-mentioned left rail clamp 4 and right rail clamp 8 installed on the bottom surface of the side beam 1 of the engineering machinery chassis. The axial limiting plate is at least three partially protruding reinforcing ribs arranged in parallel ...

Embodiment 3

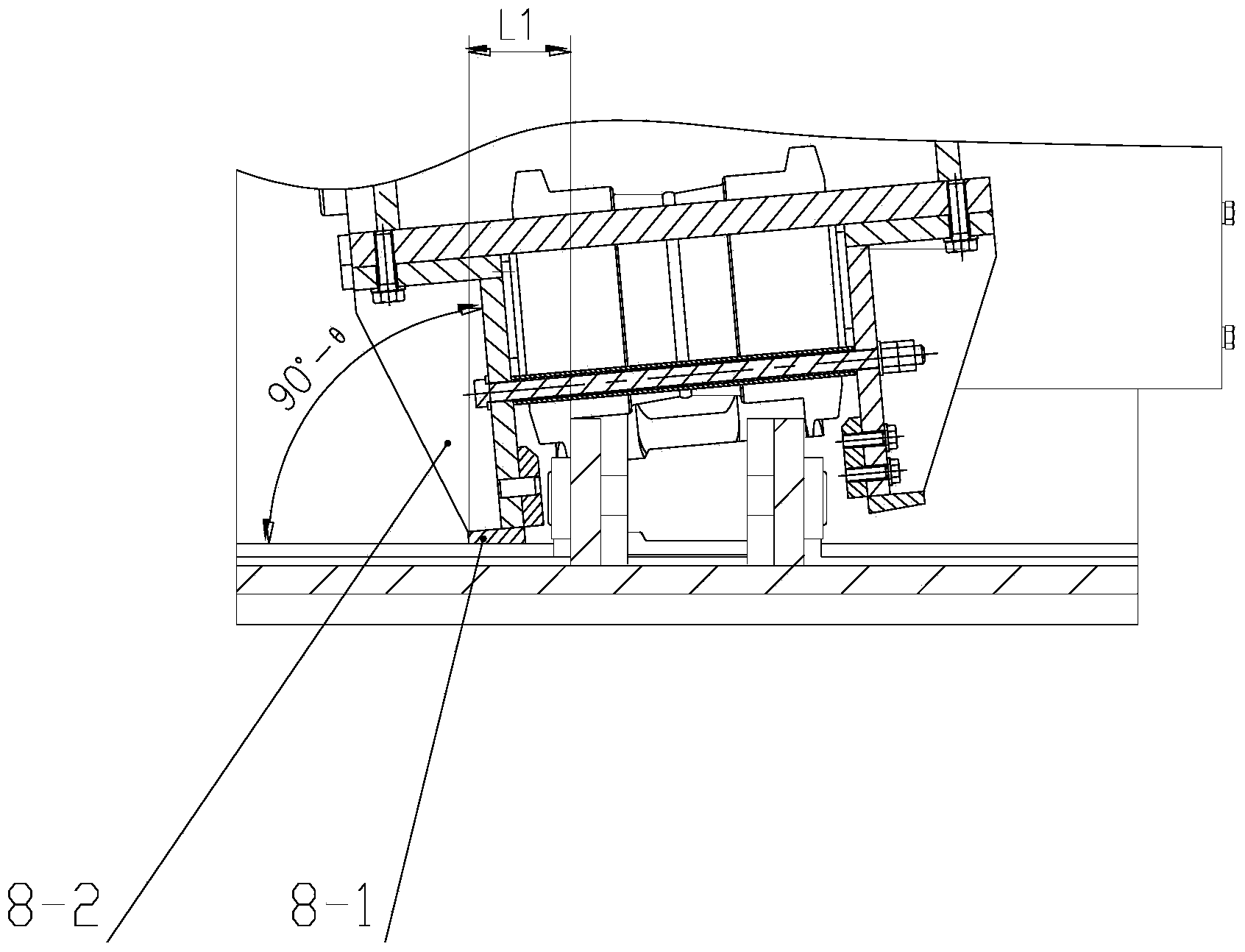

[0041] like Figure 4 , 5 As shown, the improvement of this embodiment is that the thickness of the axial limit plate 8-4 is a gradual shape with a thick top and a thin bottom, and the inclination angle θ of the clamping rail thickness 1 Defined as the angle between the two sides of the axial limit plate 8-4, the inclination angle θ of the clamp rail thickness 1 It is equal to the inclination angle θ between the track shoe and the track shoe when the lower plate of the rail clamp is installed normally. The vertical angle between the lower surface of the lower plate of the rail clamp and the inner surface of the axial limit plate 8-4 facing the chain rail is 90°±0.005. That is to say, it is necessary to control the tolerance of the above-mentioned vertical angle to be ±0.005.

[0042] The rail clamp of this embodiment provides the most suitable inclination angle. When the ground is uneven or the center of gravity of the whole machine deviates from the center of gravity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com