A floating platform and method for maintaining floating state and stability control during loading and unloading thereof

A floating platform, no-load state technology, applied in the direction of floating buildings, etc., can solve the problem of increasing the oil content of ballast water, and achieve the effect of reducing the requirements of the heating system, improving the space utilization rate, and reducing the layout of the piping system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1 loading and unloading process

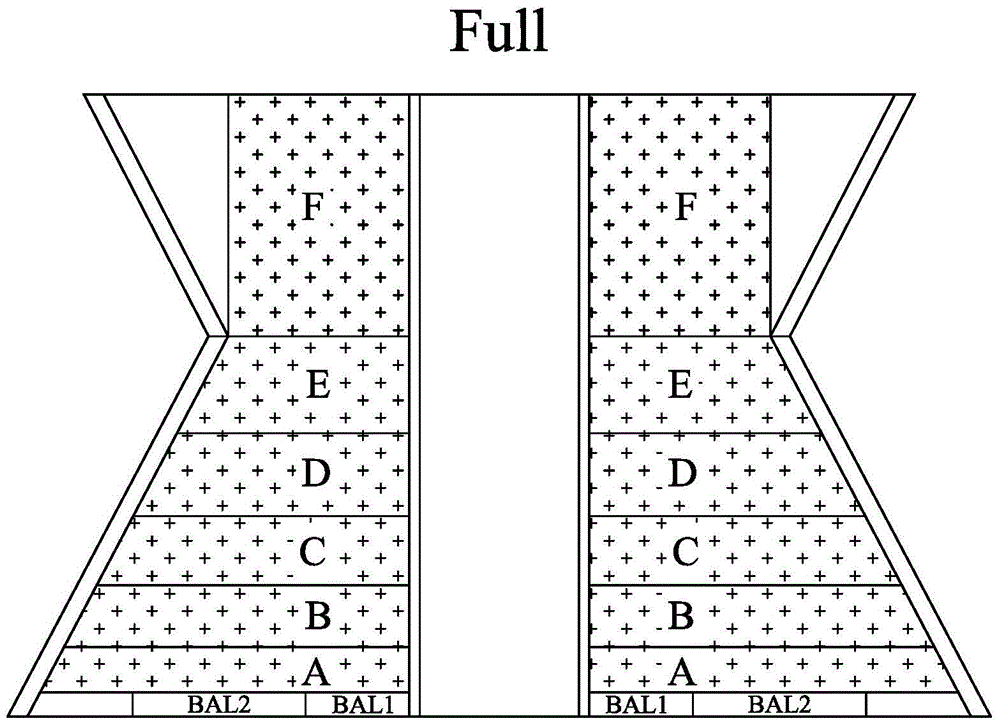

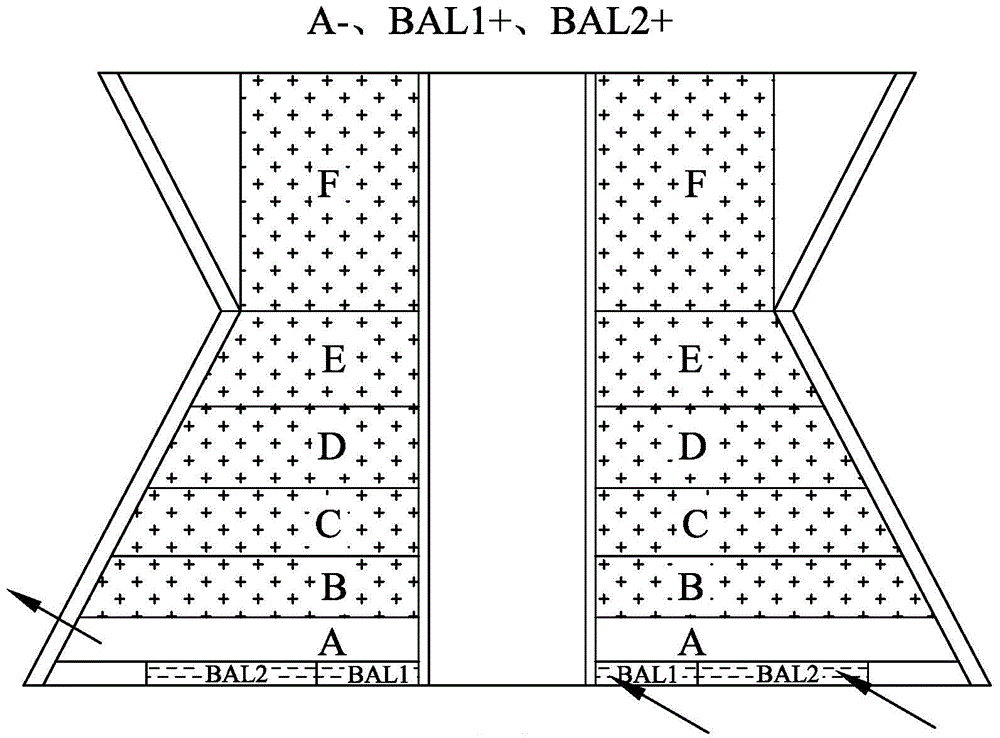

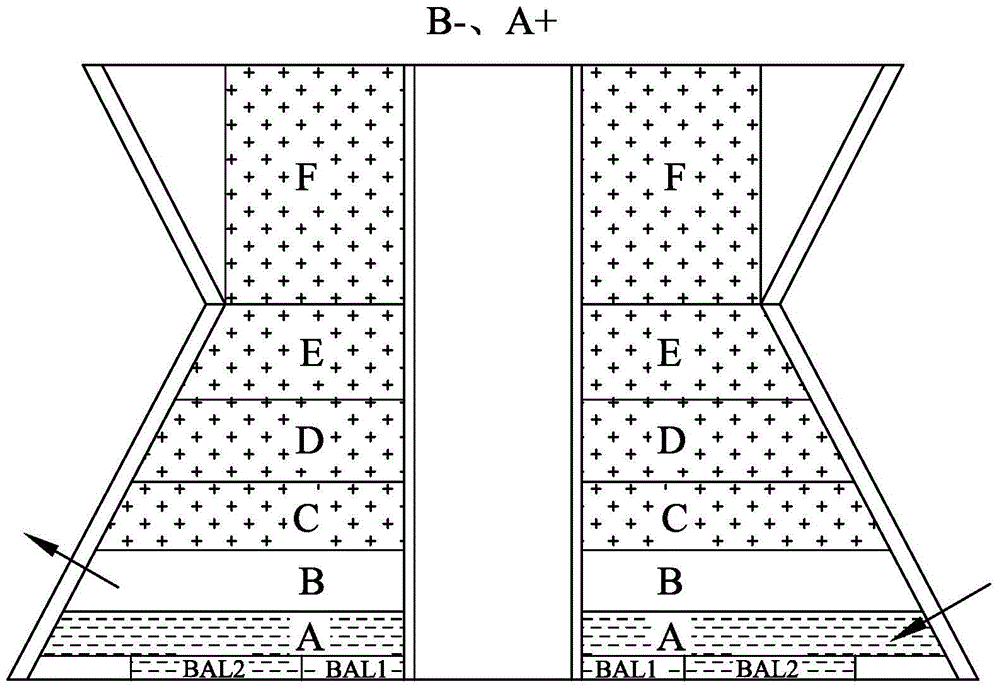

[0062] In order to ensure that the vertical position of the center of buoyancy does not change, and to limit the vertical change of the center of gravity to always be within a safe and controllable range, in conjunction with the above subdivision design, the present invention formulates a set of innovative loading and unloading procedures.

[0063] If the platform has a drilling function unit, it is generally divided into two working conditions, that is, the drilling working condition and the production oil recovery working condition. In drilling conditions, ballast water is also used to adjust the floating state of the platform to ensure that the waterline surface of the platform is always at the full-load waterline. This process is clear and not specifically described here. For ease of understanding, the loading and unloading process of production oil production conditions is divided into two stages and explained separatel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com