Magnesium ramming mass for repairing annular shaft kiln and preparation method thereof as well as method for repairing annular shaft kiln

A technology of annular sleeve and repair method, which is applied in the direction of lining repair, etc., can solve the problems of falling off of refractory materials, large change rate of reburning line, and falling off of repaired parts, so as to meet the overall stress strength, uniform overall force, and guarantee effect of effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

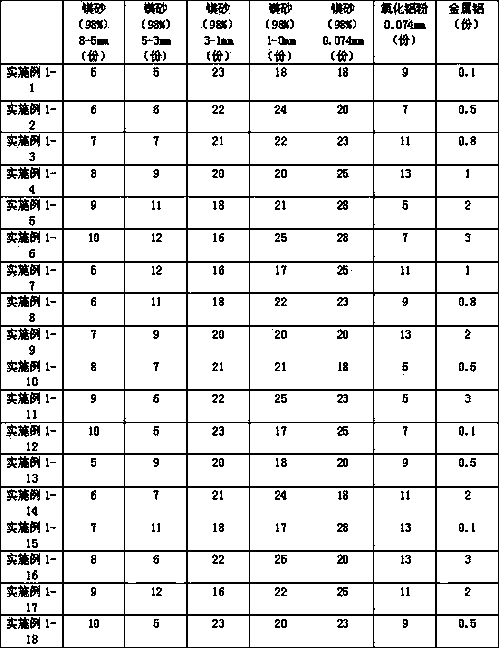

Examples

Embodiment 2

[0035] Example 2 Restoration of Annular Sleeve Kiln

[0036] (1) Set up scaffolding at the lower part of the lower arch bridge of the annular sleeve kiln; when the scaffolding is erected at the lower part of the lower arch bridge, use 12 membranes to stabilize the 6 lower arch bridges;

[0037] (2) The membrane is fixedly installed on the scaffolding, and it is strictly forbidden to load with the arch bridge when the membrane is installed. The fetal membrane must be firmly fixed to the scaffold, and the upper fetal membrane should not be displaced when the scaffold is used.

[0038] (3) After all the membranes are in place, install the corbels symmetrically; the corbels are made of 12*150*300 (rib plate 10*150) Q235B steel plates; the welding rods are E40 welding rods; The insulation bricks are hollowed out, and special personnel must be sent to observe the status of each arch bridge during construction, and they must be evacuated immediately if problems are found.

[0039] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com