FRP component with ribs and construction method for combination between FRP component and concrete

A technology of concrete and components, applied in bridge parts, erection/assembly of bridges, bridges, etc., can solve the problems of high mold production cost, high production cost, and difficulty in ensuring the formation of high-pressure colloid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

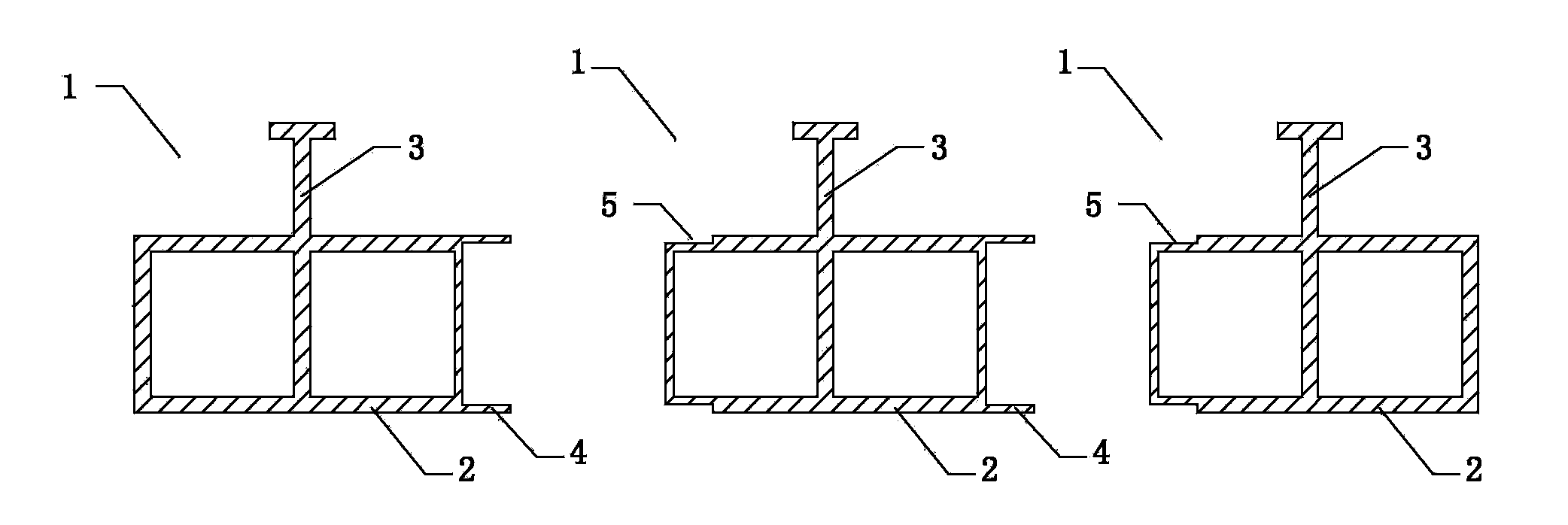

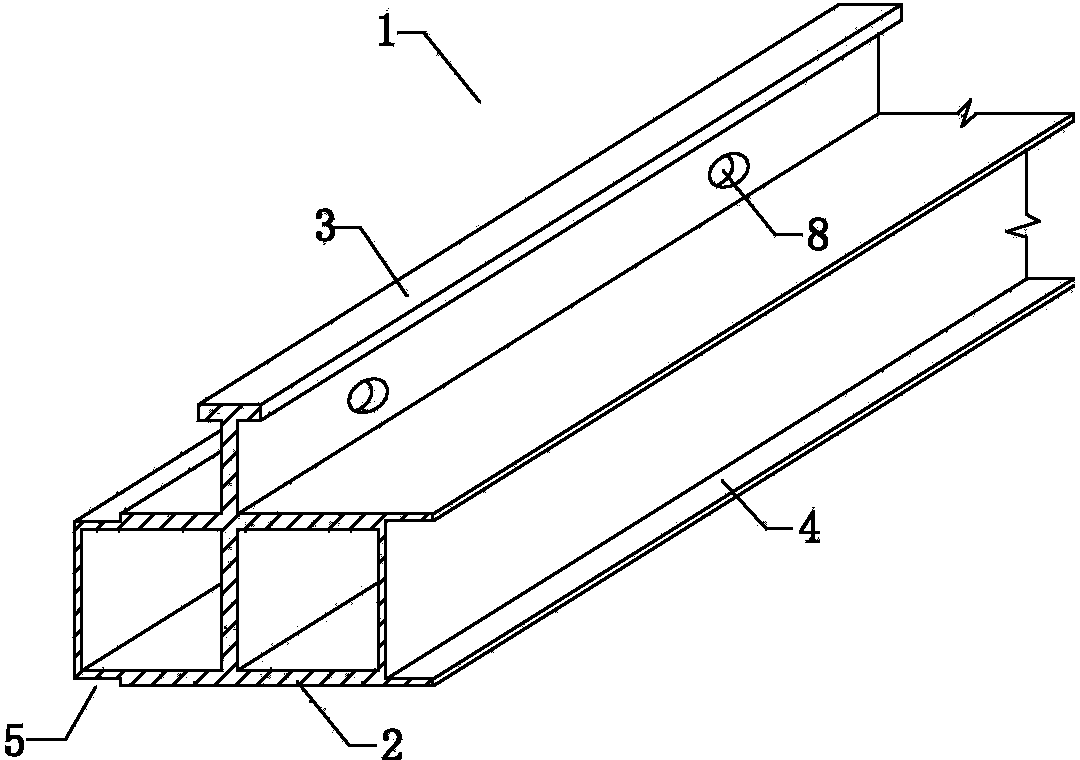

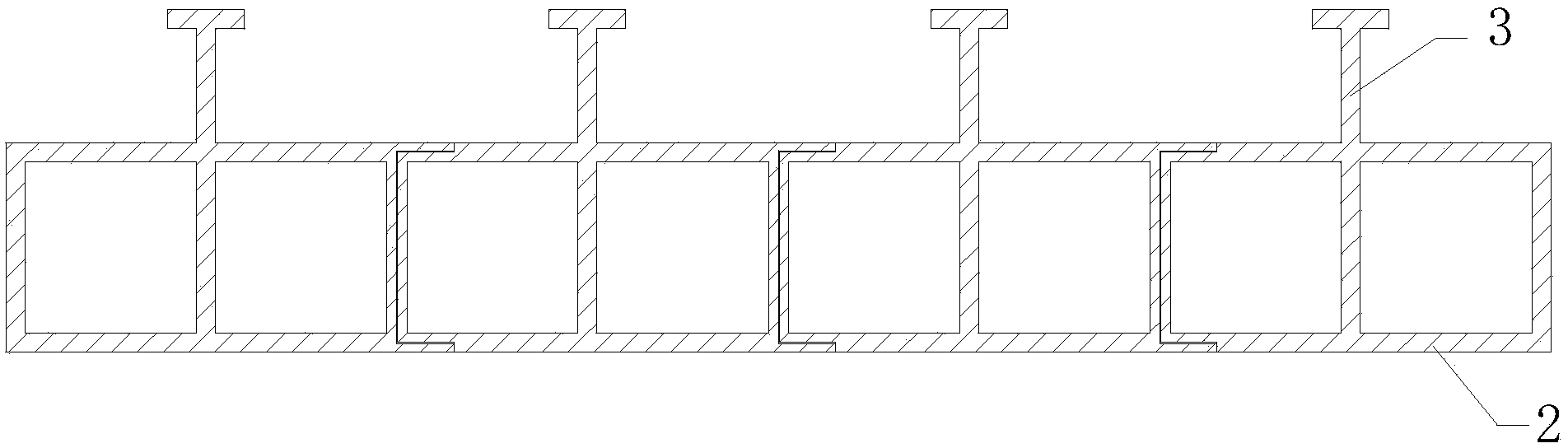

[0027] The invention is attached Figure 1-15 shown.

[0028] A ribbed FRP member, comprising an FRP basic block 1, and the FRP basic block 1 is divided into two parts: the lower FRP basic bottom plate 2 and the upper FRP basic longitudinal plate rib 3, the side wall of the FRP basic bottom plate 2 A convex key 4 and / or a concave key 5 are added. Only one of the convex key 4 or concave key 5 is provided on the FRP basic base plate 2 of the FRP basic block 1 located at the end, and the FRP basic base plate 2 of the FRP basic block 1 located at the non-end is also provided with a convex key 4 or a concave key 5. The size and position of the key 4 and the concave key 5, the convex key 4 and the concave key 5 are adapted to each other, such as Figure 1~2 shown. In this way, a plurality of FRP basic building blocks 1 form a ribbed FRP member through the interlocking connection of the protruding keys 4 provided on themselves and the grooves 5, such as Figure 3-4 shown.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com