Internal combustion engine energy-saving device

An energy-saving device and internal combustion engine technology, applied in the direction of internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of reducing the output power of internal combustion engines, complex devices, and prone to failure, so as to increase the amount of generation, stability, and fuel consumption Effect of reducing and preventing knocking phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

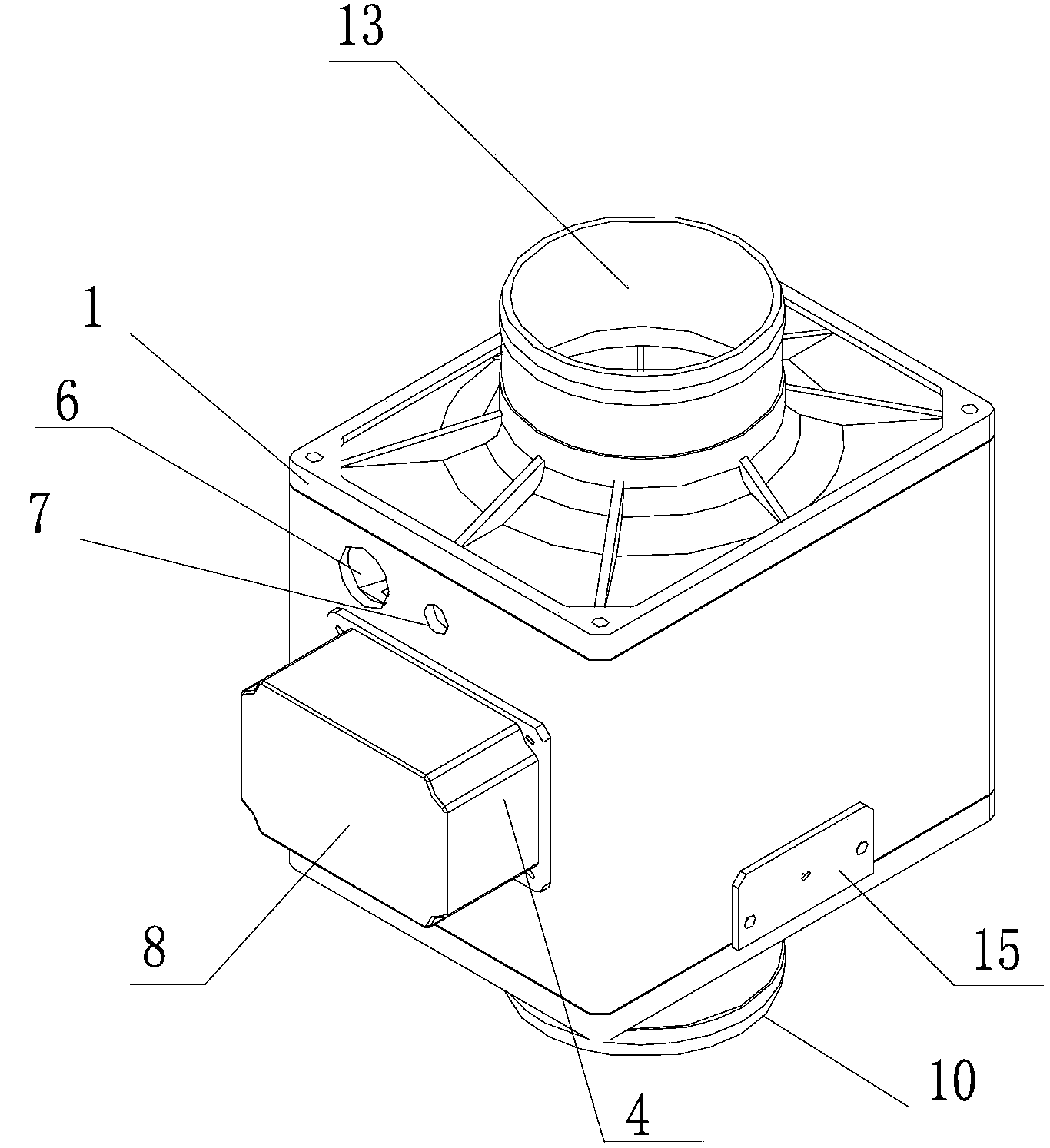

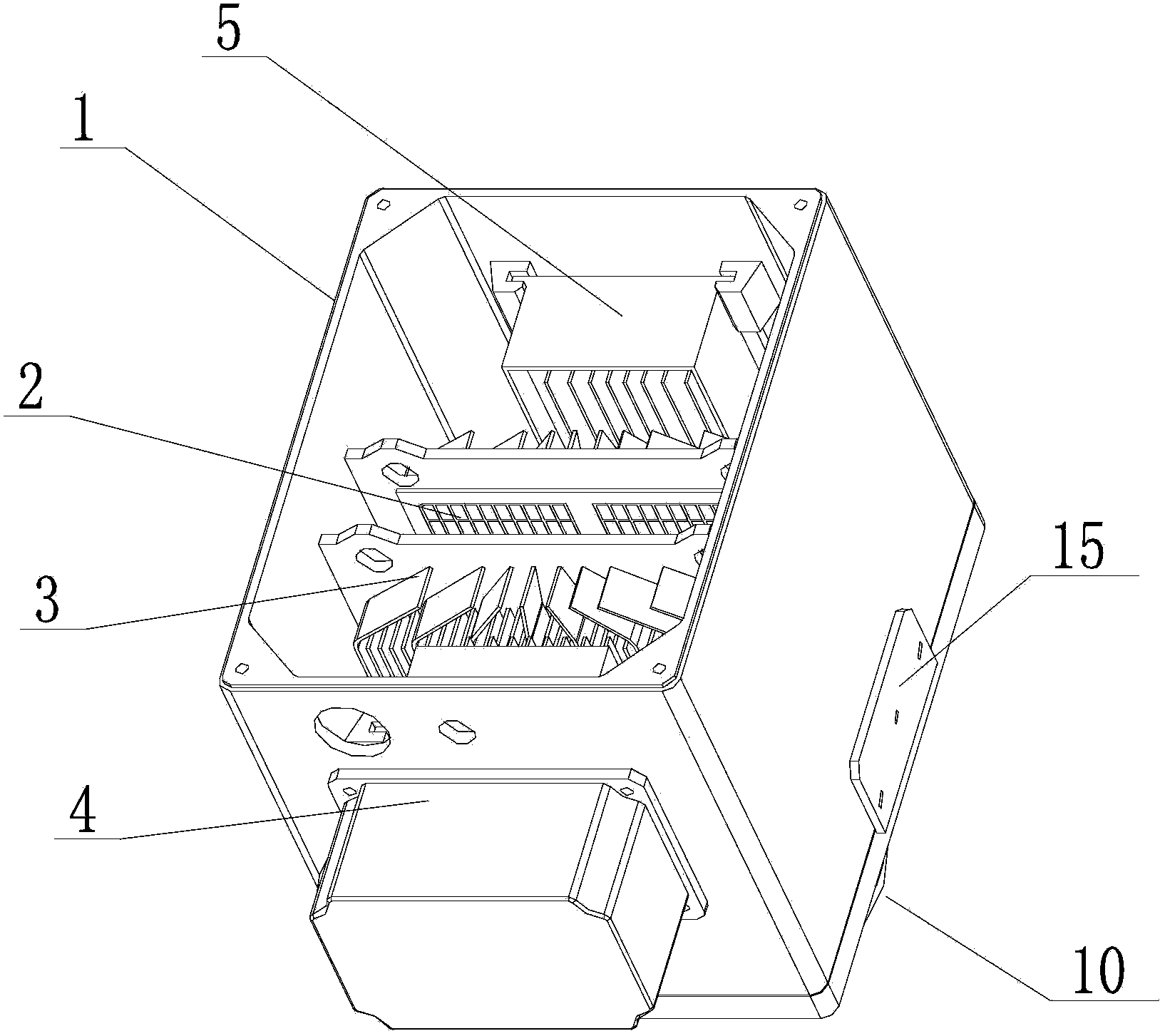

[0019] The energy-saving device for an internal combustion engine of the present invention comprises a housing 1 which is hollow inside. The opposite sides of the housing 1 are provided with an air inlet 13 and an air outlet 10. The air inlet 13 communicates with the intake pipe of the internal combustion engine, and the air outlet 10 communicates with the engine of the internal combustion engine. , the inside of the housing 1 is located between the air inlet 13 and the air outlet 10 and is provided with two opposite heat sinks 3, and the opposite faces of the two heat sinks 3 are provided with an ozone generating sheet 2, and the two heat sinks 3 are opposite to each other. A high-voltage power supply 5 is respectively provided between the surface and the surface of the corresponding housing 1, and the high-voltage power supply 5 is electrically connected to the ozone generator 2. The side of the housing 1 is provided with an intelligent controller 4, and the intelligent contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com