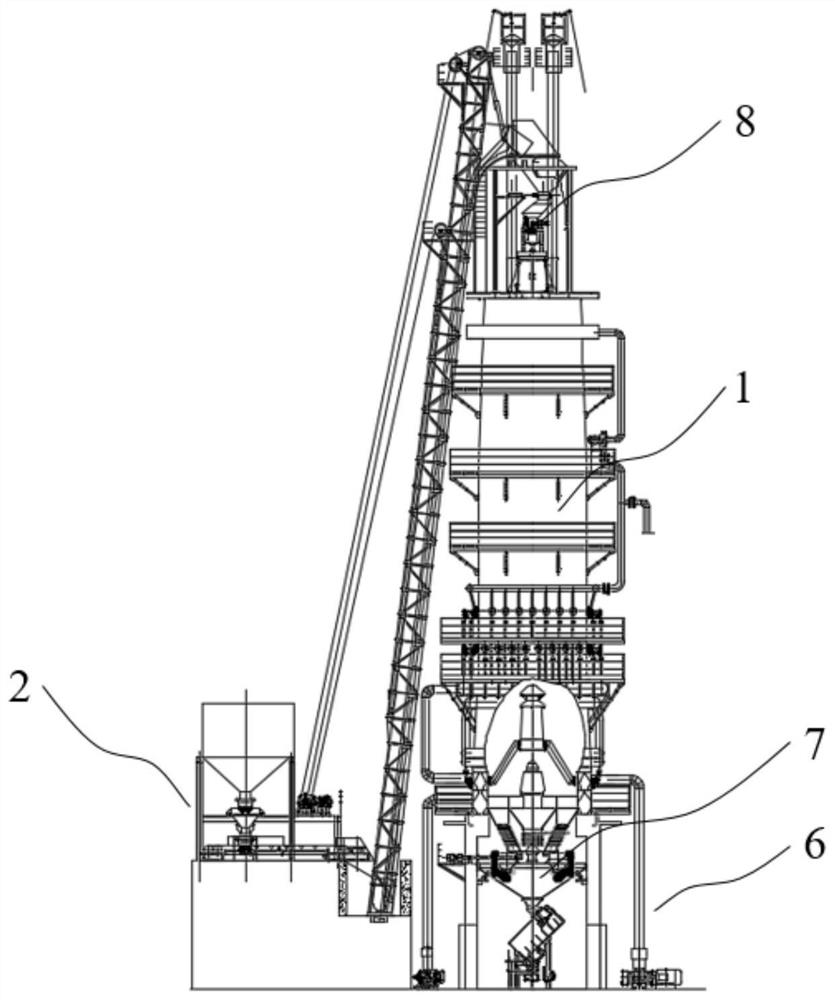

Process and device for co-production of active lime from natural gas and biomass fuel

A technology of biomass fuel and active lime, which is applied in the field of lime production in lime kilns, can solve the problems of mixed combustion that cannot inject solid powder fuel, long calcination time, and low safety, and achieves various production processes and short calcination time , high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

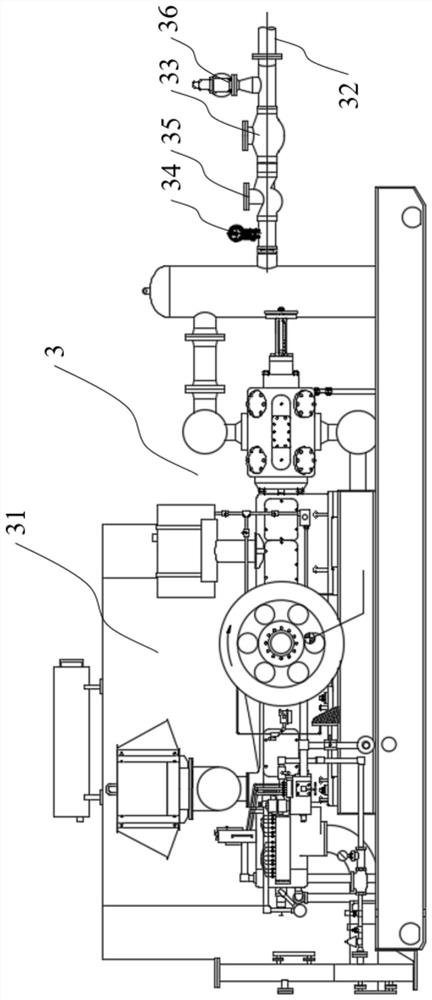

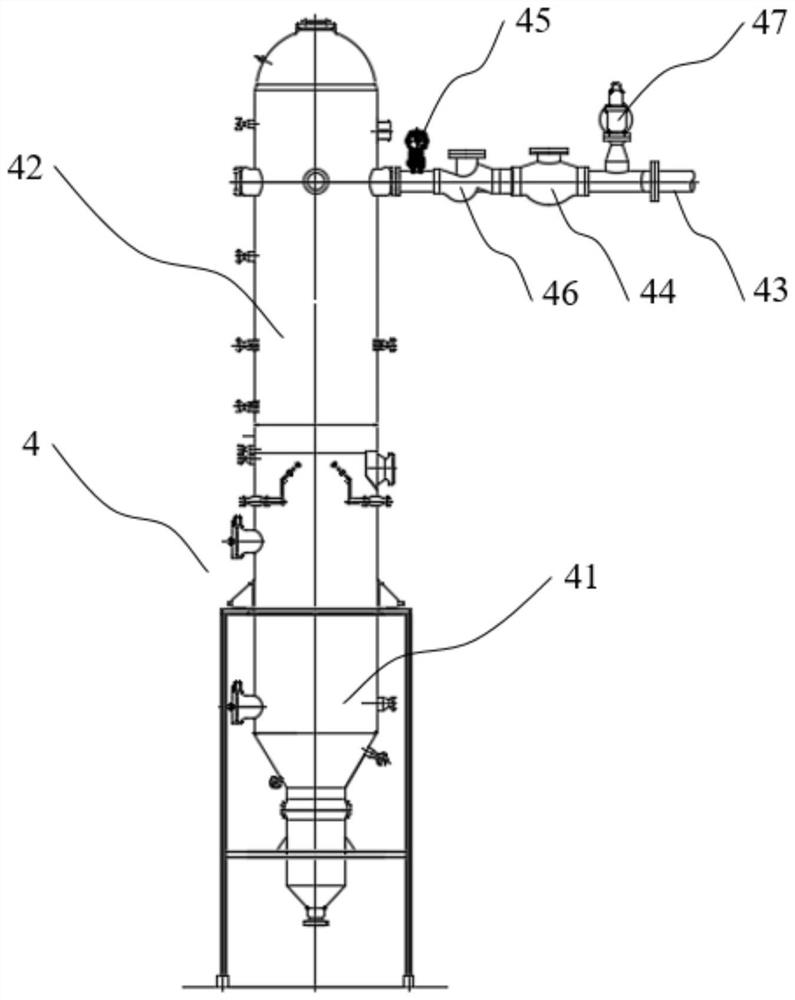

[0065] The present application will be further described in detail below with reference to the accompanying drawings through specific embodiments.

[0066] In the description of this application: unless stated otherwise, "plurality" means two or more. The terms "first", "second", "third", etc. in the present application are intended to distinguish the objects they refer to, and do not have special meanings in terms of technical connotations (for example, they should not be construed as important degree or order, etc. emphasis). The expressions "including", "comprising", "having", etc. also mean "not limited to" (certain elements, components, materials, steps, etc.).

[0067] Terms such as "up", "down", "left", "right", "middle", etc. quoted in this application are usually for the convenience of intuitive understanding with reference to the accompanying drawings, rather than absolute positional relationships in actual products. limited. In the case of not departing from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com