Undersea sealing system, tidal power generation unit applying same and application method

A technology of sealing system and generator set, applied in the field of sealing, which can solve the problems of poor sealing performance, low service life of sealing ring, dry friction of sealing ring, etc., so as to increase service life and sealing performance, avoid destructive accidents, and ensure sealing performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

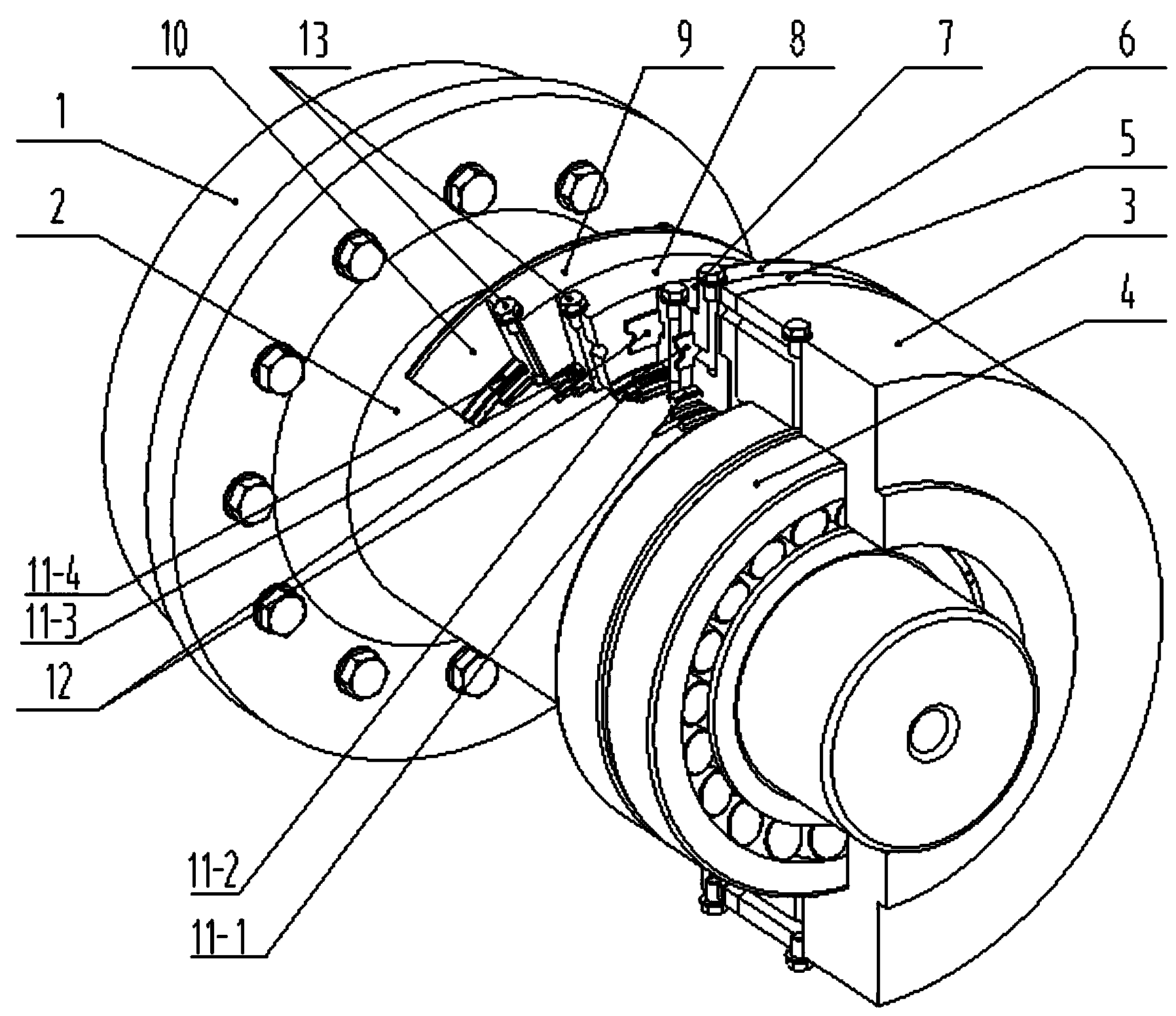

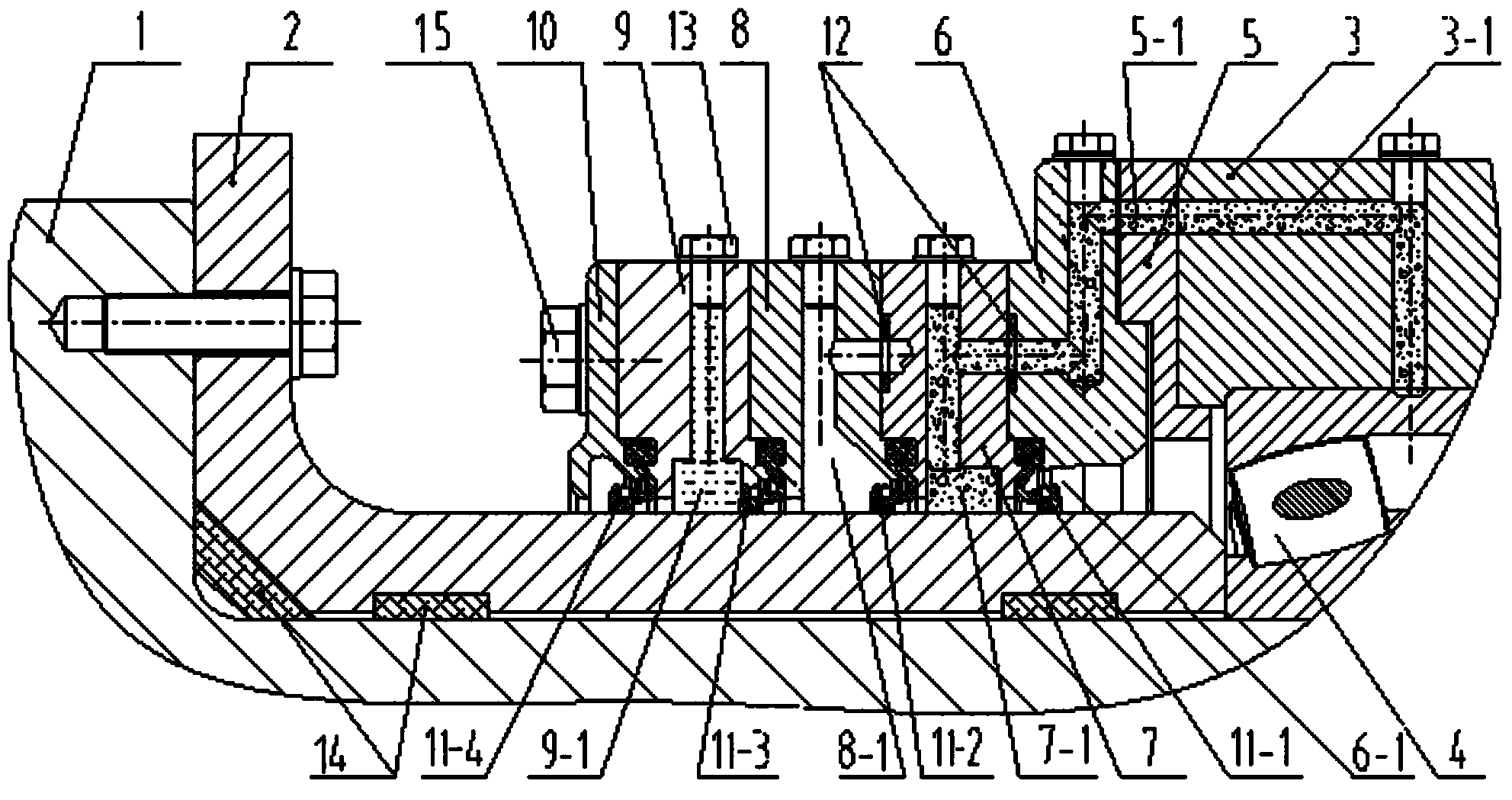

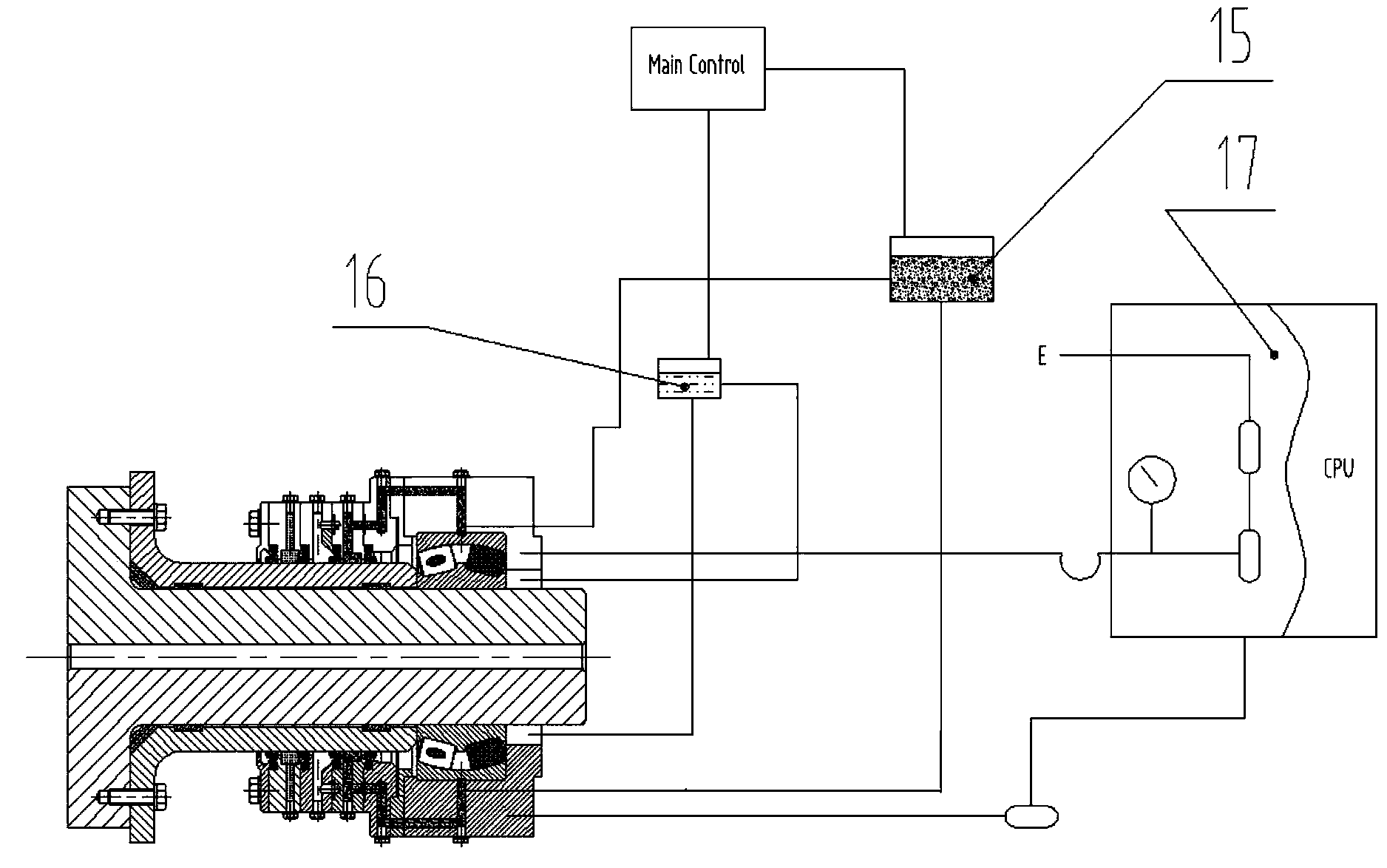

[0039] The invention provides an underwater sealing system, which is used for the sealing connection between the underwater non-rotating parts and the rotating parts. Applying this sealing method to the seawater underwater tidal energy generator set can effectively protect the transmission shaft and the engine room for a long time. Make a seal.

[0040] see figure 1 , figure 2 As shown, the transmission shaft 1 is used as an underwater rotating part, and the shaft sleeve 2 is sleeved on it. In order to strengthen the sealing performance, the inner wall of the shaft sleeve 2 is provided with multiple annular grooves, and a sealing ring 14 is installed in the groove. The underwater sealing system of the present invention includes a dynamic seal and a seal body set on the shaft sleeve 2, the seal body forms a pressure chamber on both sides of the dynamic seal, and the dynamic seal is strengthened by the pressure difference between the pressure chambers on both sides. Sealed co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com