Expanded connection structure assembly for heat sinks

An expansion joint and heat sink technology, applied in lighting and heating equipment, cooling/heating devices of lighting devices, point light sources, etc., can solve the problems of reduced reliability of screw connections, affecting heat dissipation, and affecting the firmness of installation, etc., to achieve Save manufacturing and use costs, good heat conduction effect, and avoid the effect of heat sink falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

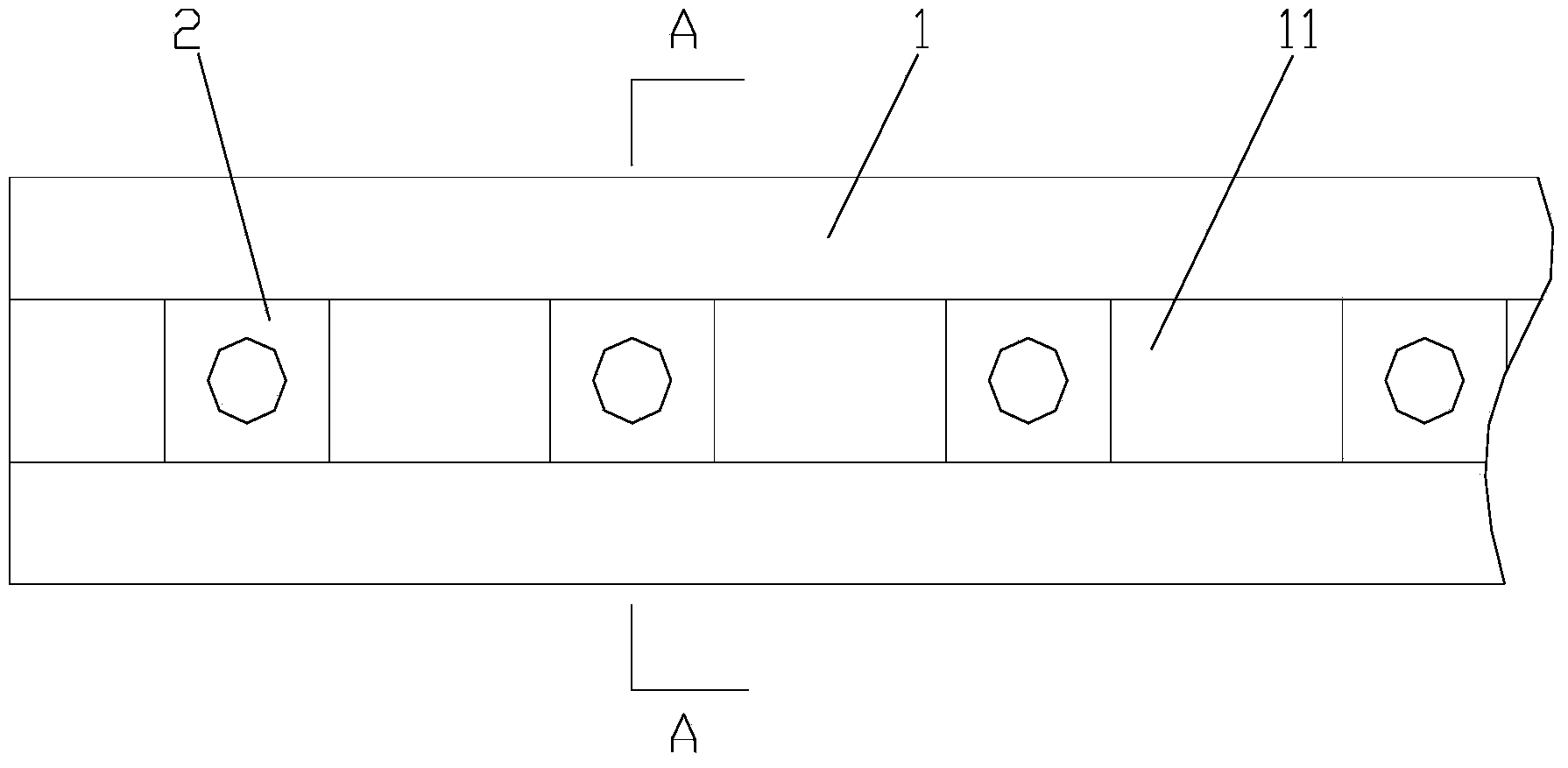

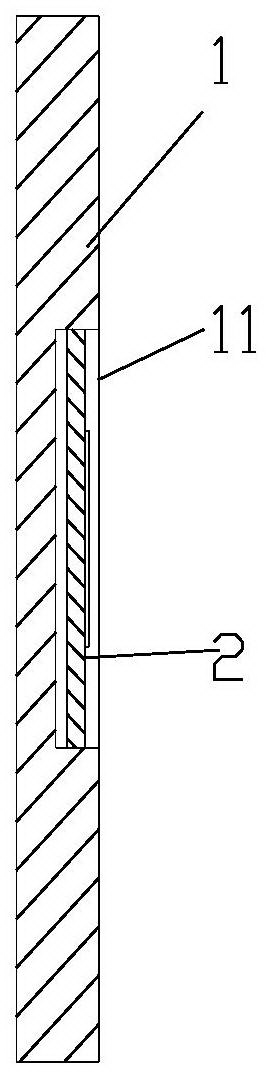

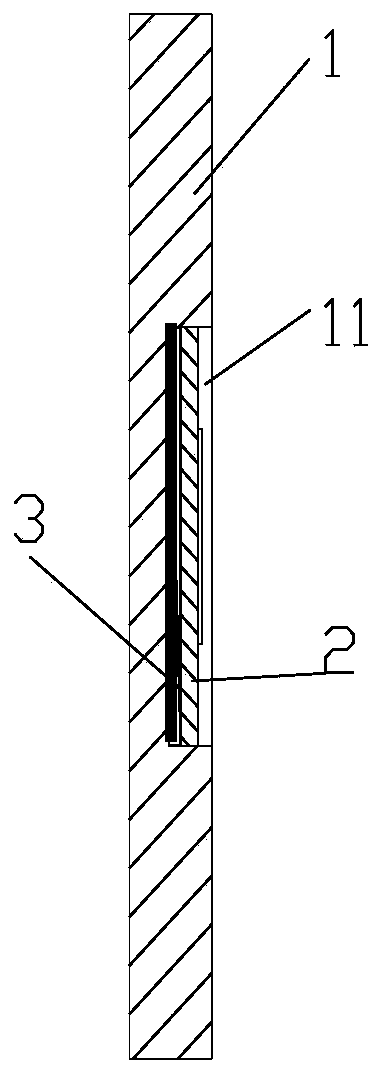

[0022] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 A cross-sectional view along the A-A direction (there is a gap between the bottom surface of the heat sink and the bottom of the expansion groove), as shown in the figure: this embodiment takes an LED lamp as an example, of course, it is also applicable to solar cells and other equipment with heat dissipation requirements; the heat sink The expansion joint structure assembly includes a heat dissipation base plate 1 and a heat sink 2. The surface of the heat dissipation base plate 1 is provided with an expansion joint groove 11. In the expansion slot 11; the heat dissipation substrate is generally made of materials with good thermal conductivity, such as aluminum or copper, and more and transparent heat dissipation fins are set if necessary, which will not be repeated here; The interference fit is located on the side, and there is no need to apply a large pressure on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com