Intelligent rapid film loader

A film loading machine, fast technology, applied in the field of analog X-ray machine filming and film processing, to achieve the effects of simplifying filming procedures, preventing accidental exposure, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

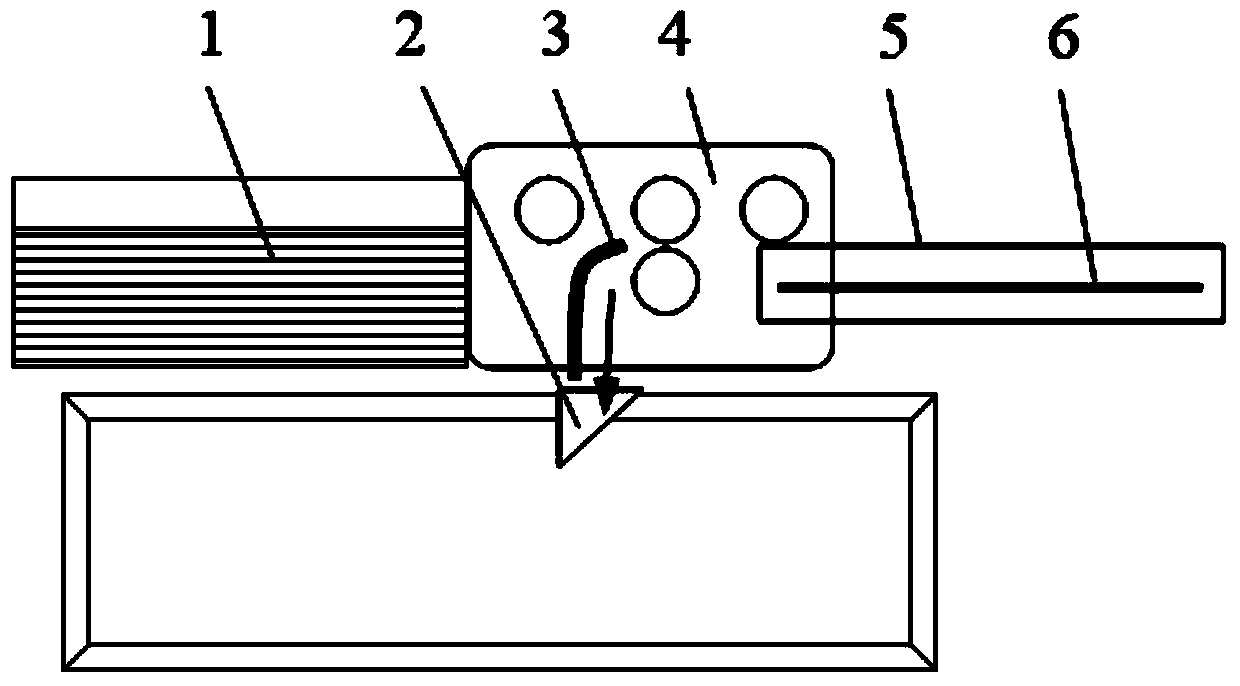

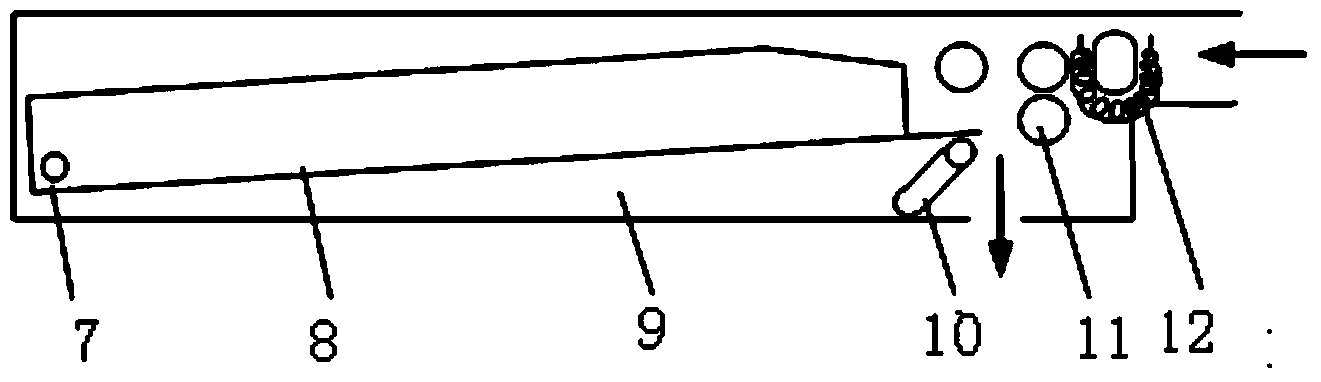

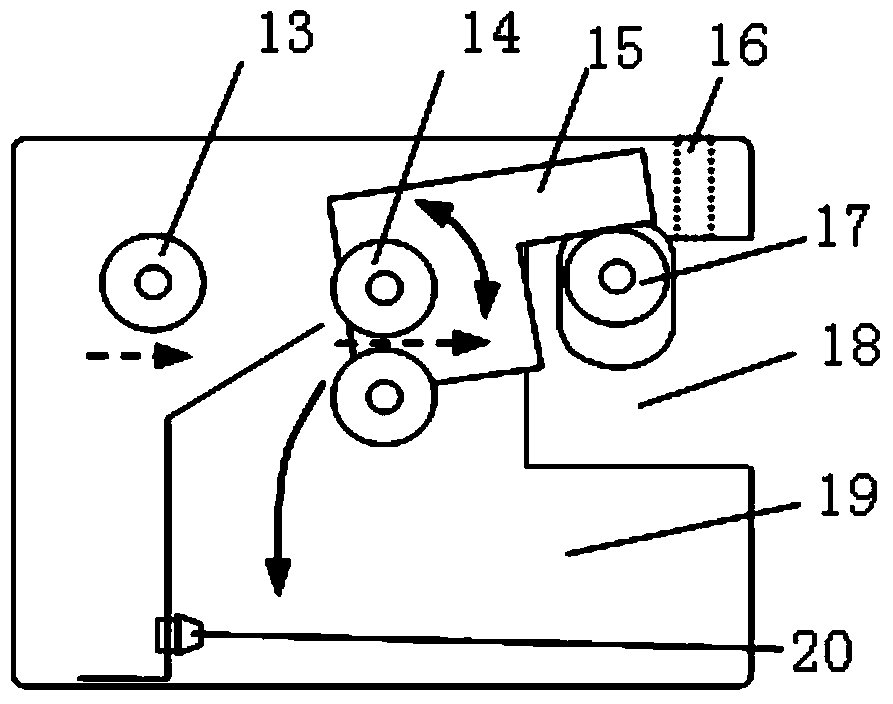

[0034] The intelligent fast loading machine provided by the present invention is an auxiliary equipment for simulating an X-ray machine and an automatic developing machine, such as Figure 1-7 As shown, when in use, first put the unexposed film into the film holder (8) of the intelligent fast film loading machine, and then stack it on the automatic film processor with the bottom shading, and the film outlet is facing the film inlet (9) of the automatic film processor. When loading unexposed film into the automatic film processor, the black cloth bag that comes with it is usually used, and the automatic film processor hood or darkroom conditions can also be used. The intelligent fast film loader has a light-shielding function, which will not cause accidental exposure of the internal film. After starting up, the intelligent fast film loading machine makes film loading or taking actions according to whether there is film in the self-locking cassette (5), without manual interventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com