Method and apparatus for the production of an arabinoxylan-enriched preparation and other co-products

A technology of arabinoxylan and preparation, which is applied in the field of preparations rich in arabinoxylan (arabinoxylan), which can solve the problem of expensive, delayed supply of arabinoxylan, and no significant reduction in viscosity, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

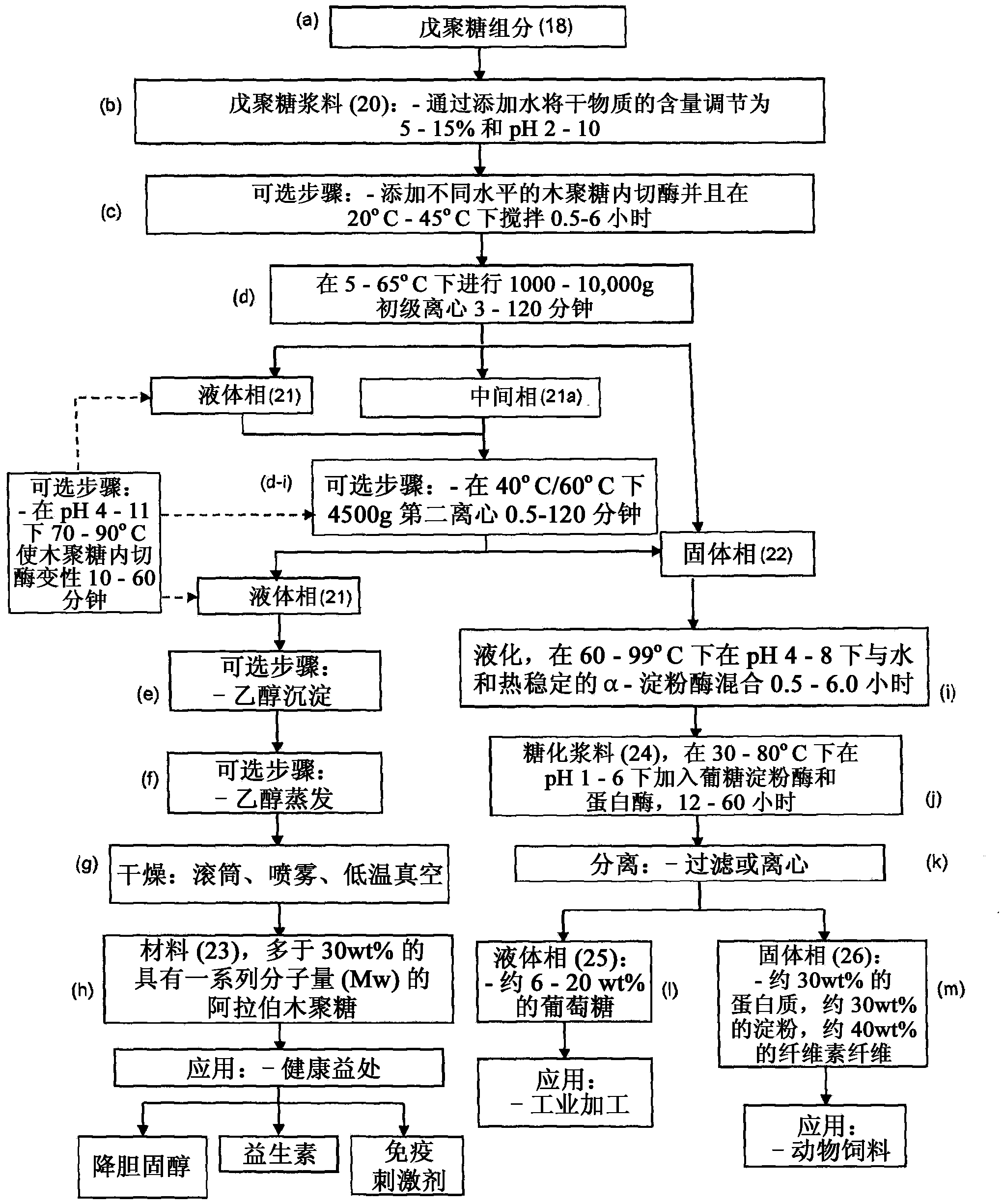

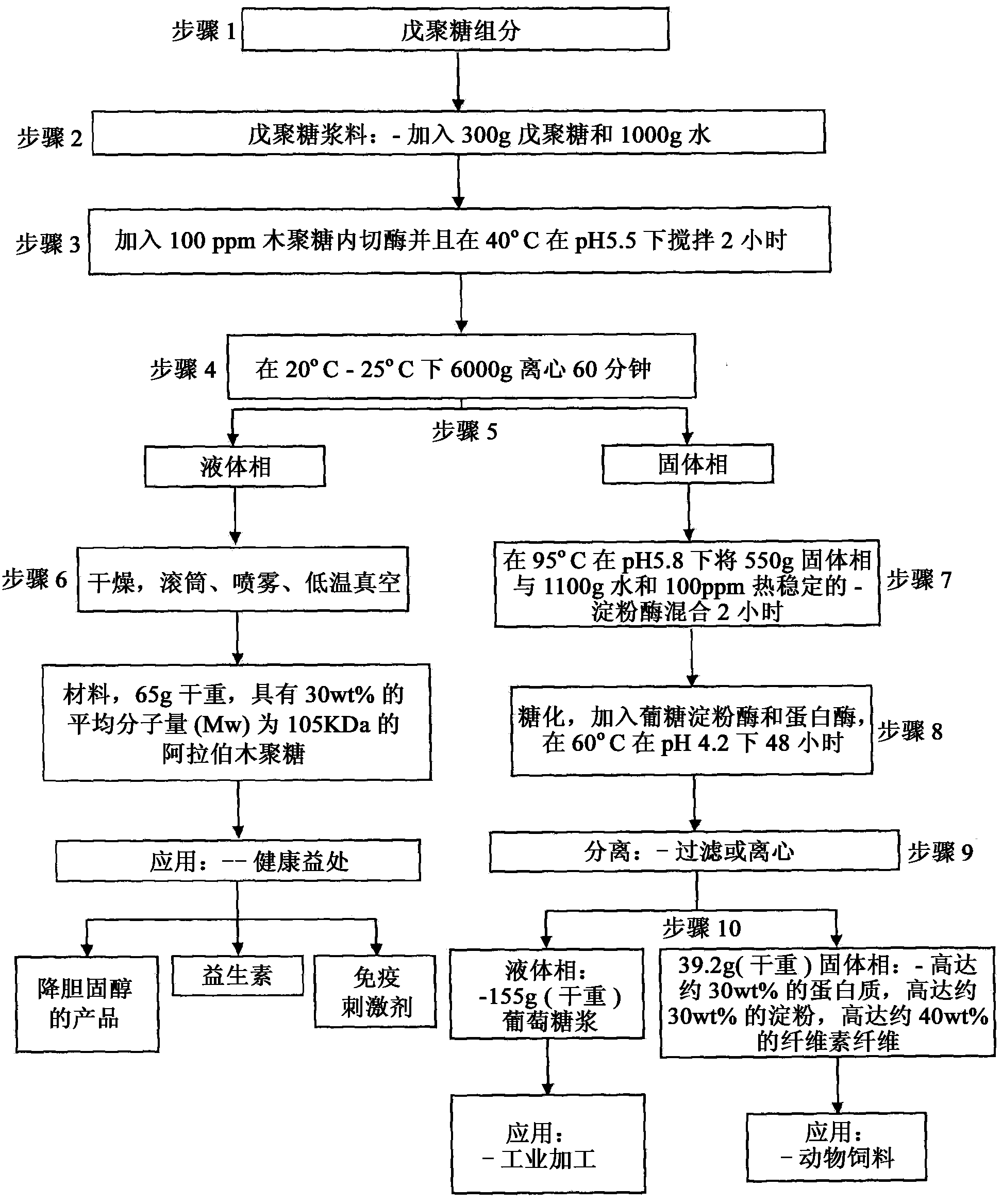

[0199] This example image 3 shown.

[0200] The following equipment was used in Example 1:

[0201]

[0202]

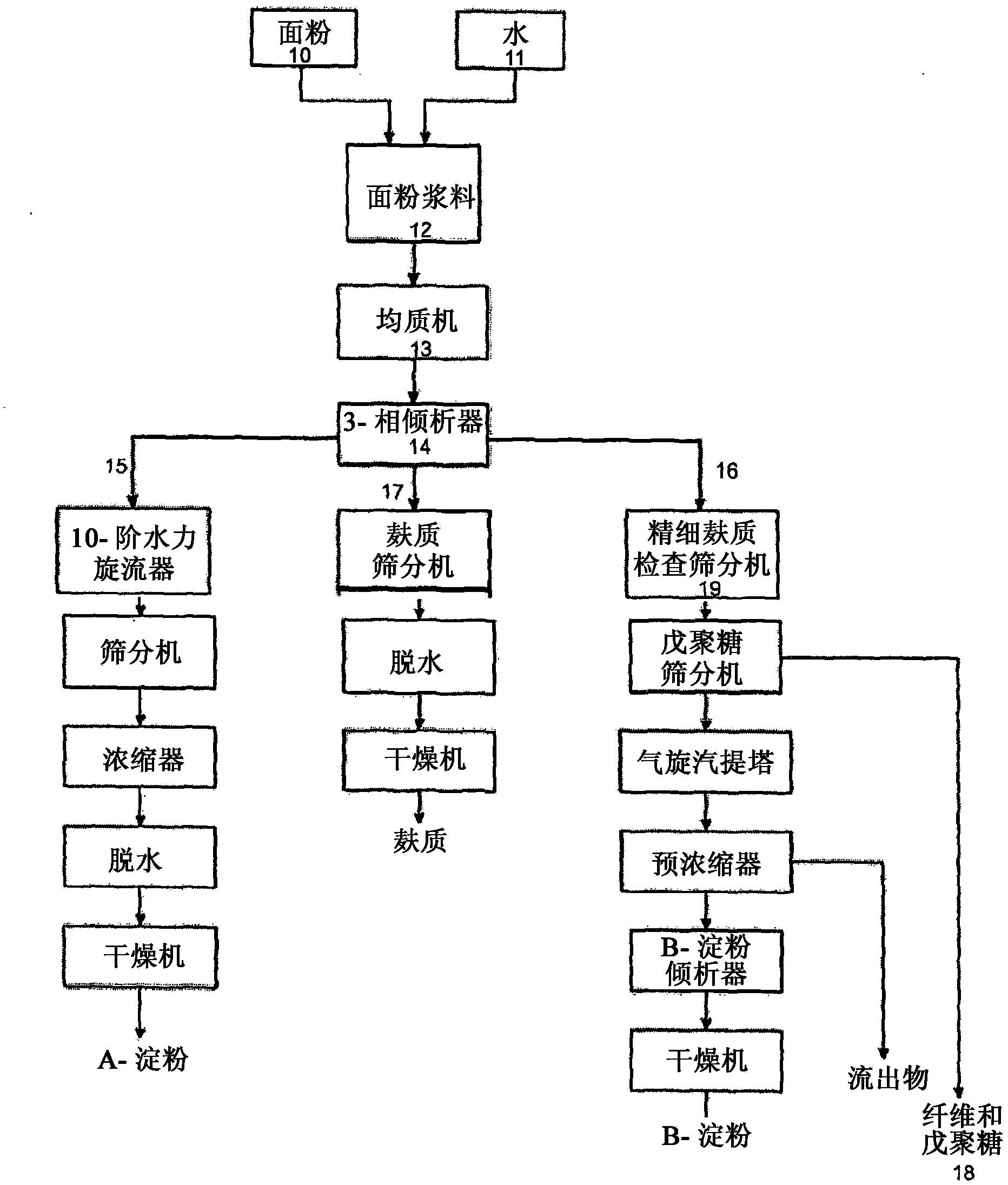

[0203] Step 1:- From eg figure 1 The pentosan fraction (18) was obtained in the indicated high pressure decomposition (HPD) process (supra).

[0204] Step 2:- Mix 300 g of pentosan component (18) with 1000 g of water to make a pentosan slurry comprising about 23 wt% pentosan component and about 77 wt% water.

[0205] Step 3:- Add endoxylanase in the amount of 100 ppm to the slurry and adjust the pH to about 5.5. The slurry was stirred for about 2 hours at a temperature of about 40°C to convert the insoluble arabinoxylan to soluble arabinoxylan. After this period, it was noted that the viscosity had decreased from above 3000cP to below 500cP ( Figure 4 ).

[0206] Step 4:- Cool the slurry and then centrifuge at room temperature (20°C-25°C) at a centrifugal force of about 6000G for about 60 minutes.

[0207] Step 5:- From 550 g of solid phase (192 g dry w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com