Method and system for detecting and correcting problematic advanced process control parameters

A process control system and process control technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of unavailable observation or analysis of APC systems, difficulties in diagnosing and correcting APC systems, and difficulties in understanding IC manufacturing systems, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

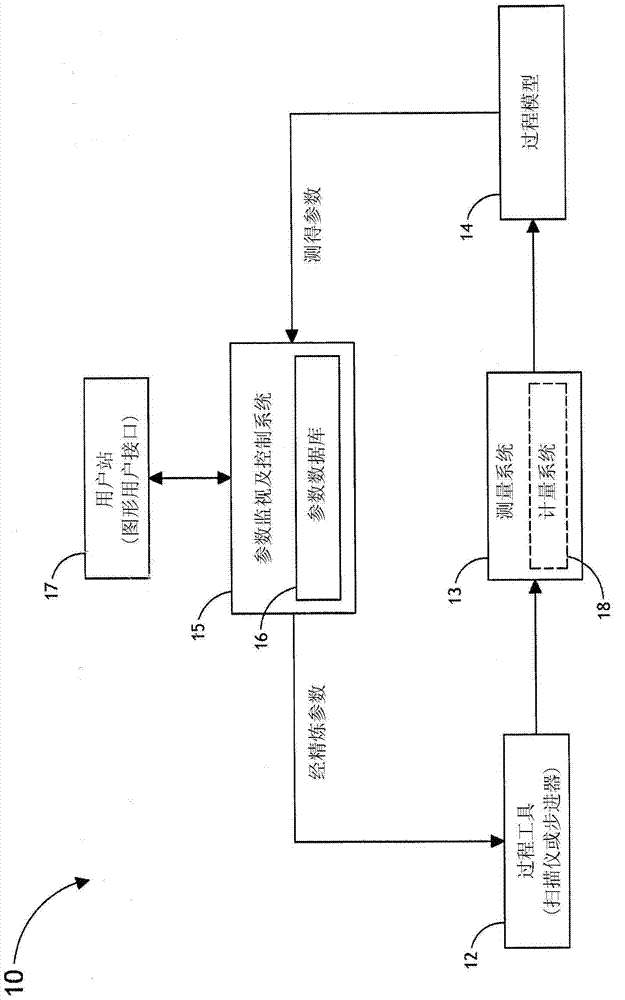

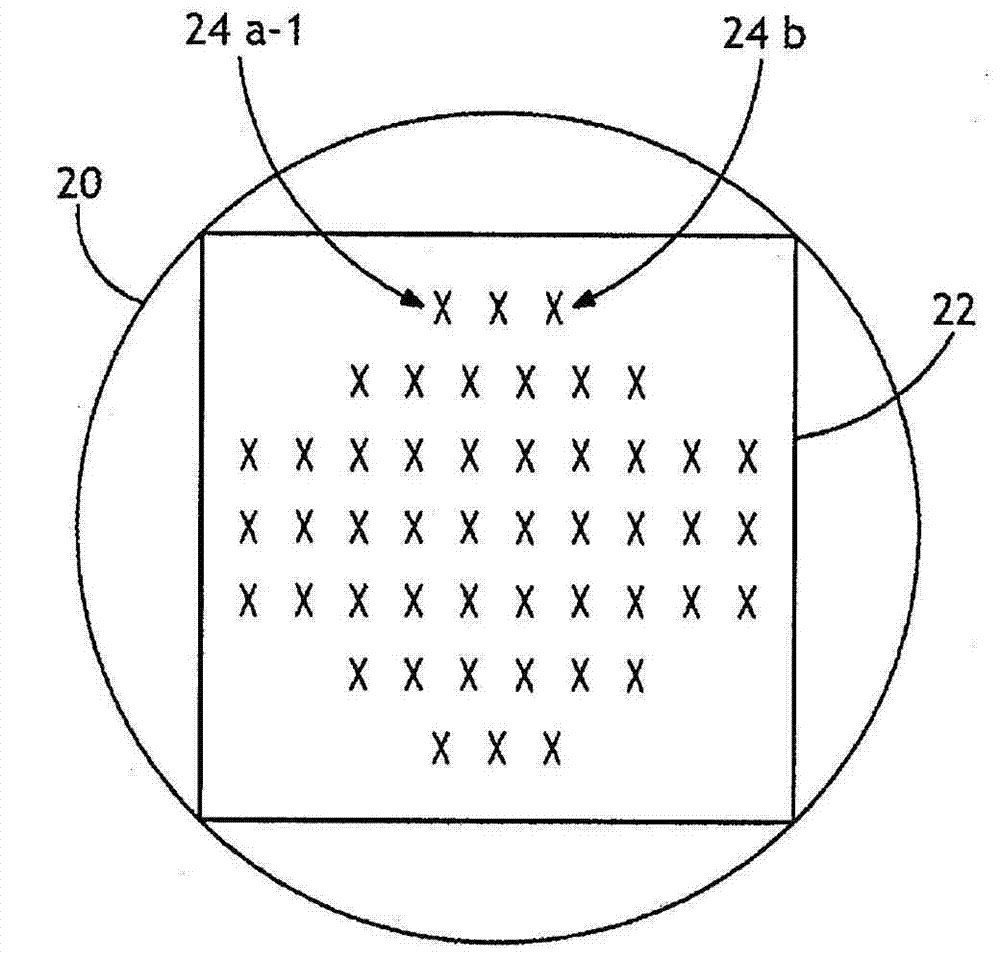

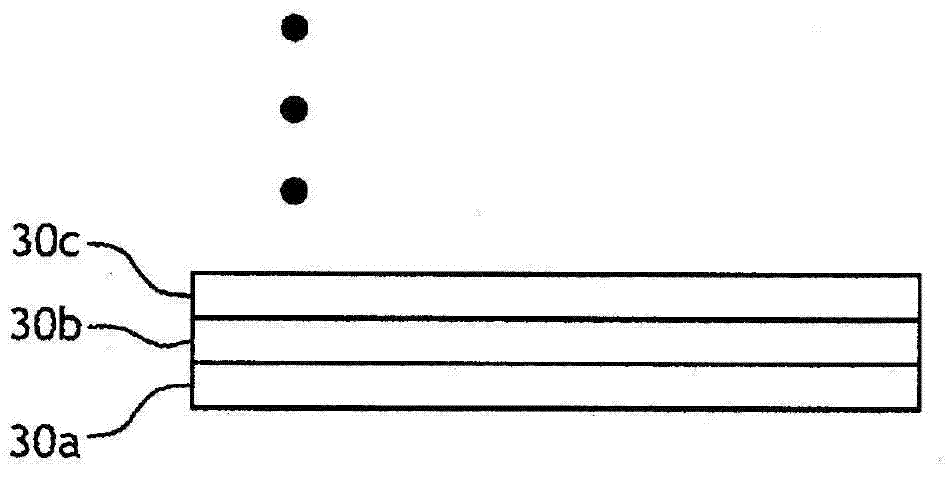

[0024] Reference will now be made in detail to the disclosed subject matter which is illustrated in the accompanying drawings. The present invention may be embodied in a system and method for monitoring and controlling feedback control in a manufacturing process, such as a photolithographic integrated circuit manufacturing process. Process control parameters in a lithographic system include, but are not limited to, translation, rotation, magnification, dose, and focus applied by a lithographic scanner or stepper operating on a given wafer (eg, a silicon wafer). Use the coverage error measure to calculate the measured parameters used in the feedback control process. These expected corrections are statistically analyzed and used to determine refined process control parameters to implement feedback control of the process control parameters applied by the scanner or stepper. Process control variables actually applied to a particular layer by a scanner or stepper are referred to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com