Automatic double-layered skin picking machine

A skin picker and double-layer technology, which is applied in the field of automatic double-layer skin pickers, can solve the problems of heating device heating, slow temperature replenishment, high defective rate of bean skin products, and large temperature fluctuations, so as to improve product quality , Easy to control by manual operation, stable temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following implementations are used to illustrate the present invention, but not to limit the scope of the present invention.

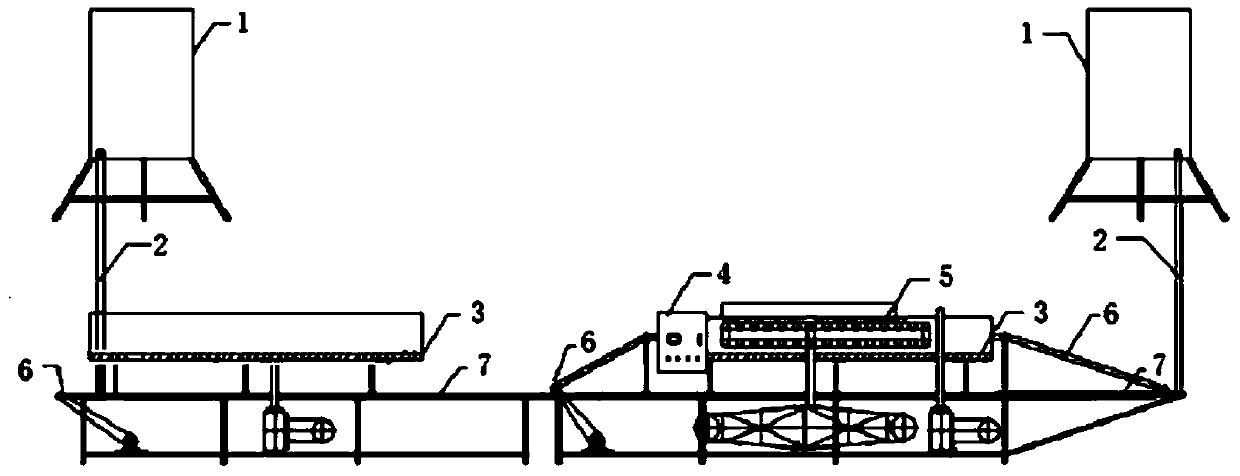

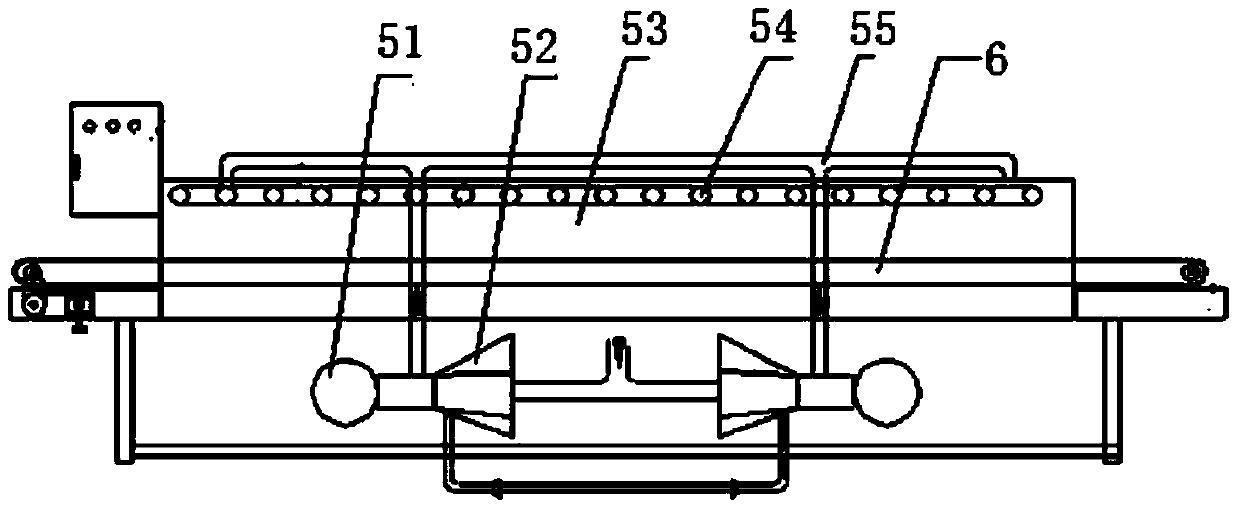

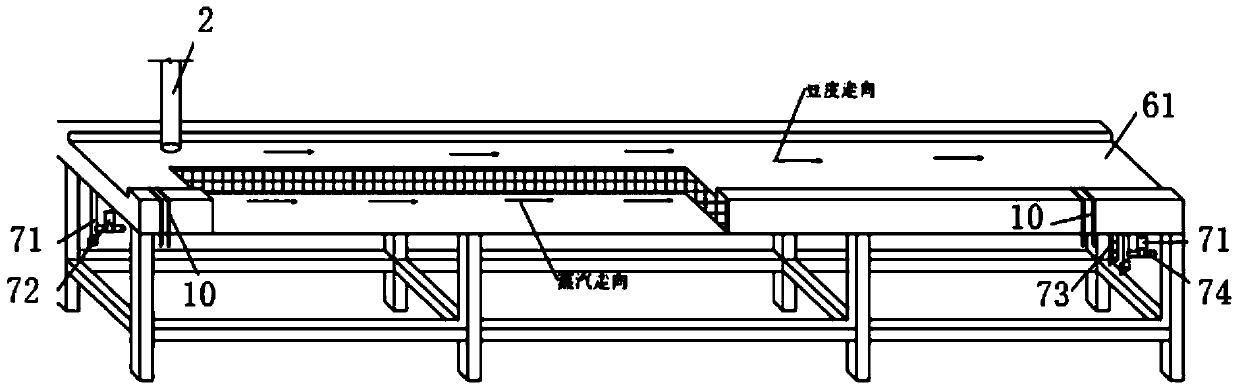

[0026] see figure 1 - Figure 4 , an automatic double-layer leather picking machine, including a grouting system, a heating system 7, a blowing system 3, a transmission system 6, a drying system 5 and a control device 4, the grouting system, a heating system 7, a blowing system 3, a transmission system 6 are equipped with two sets, which are placed on both sides and connected together through the transmission system 6 to form an interface 9. The transmission system 6 includes a frame and a channel-shaped steel plate that is adapted and combined with the frame. The steel plate forms a grout tank 61, and the grouting system includes a grouting bucket 1 and a grouting pipe 2, and the grouting bucket 1 is arranged above the side of the transmission system 6, and is opposite to the transmission system 6 through the grouting pipe 2, Make the inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com