Fly ash raw material pellet production apparatus

A technology for preparing equipment and raw pellets, which can be used in extrusion and granulation of raw materials, sustainable manufacturing/processing, chemical industry, etc., and can solve problems such as increasing sintering energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

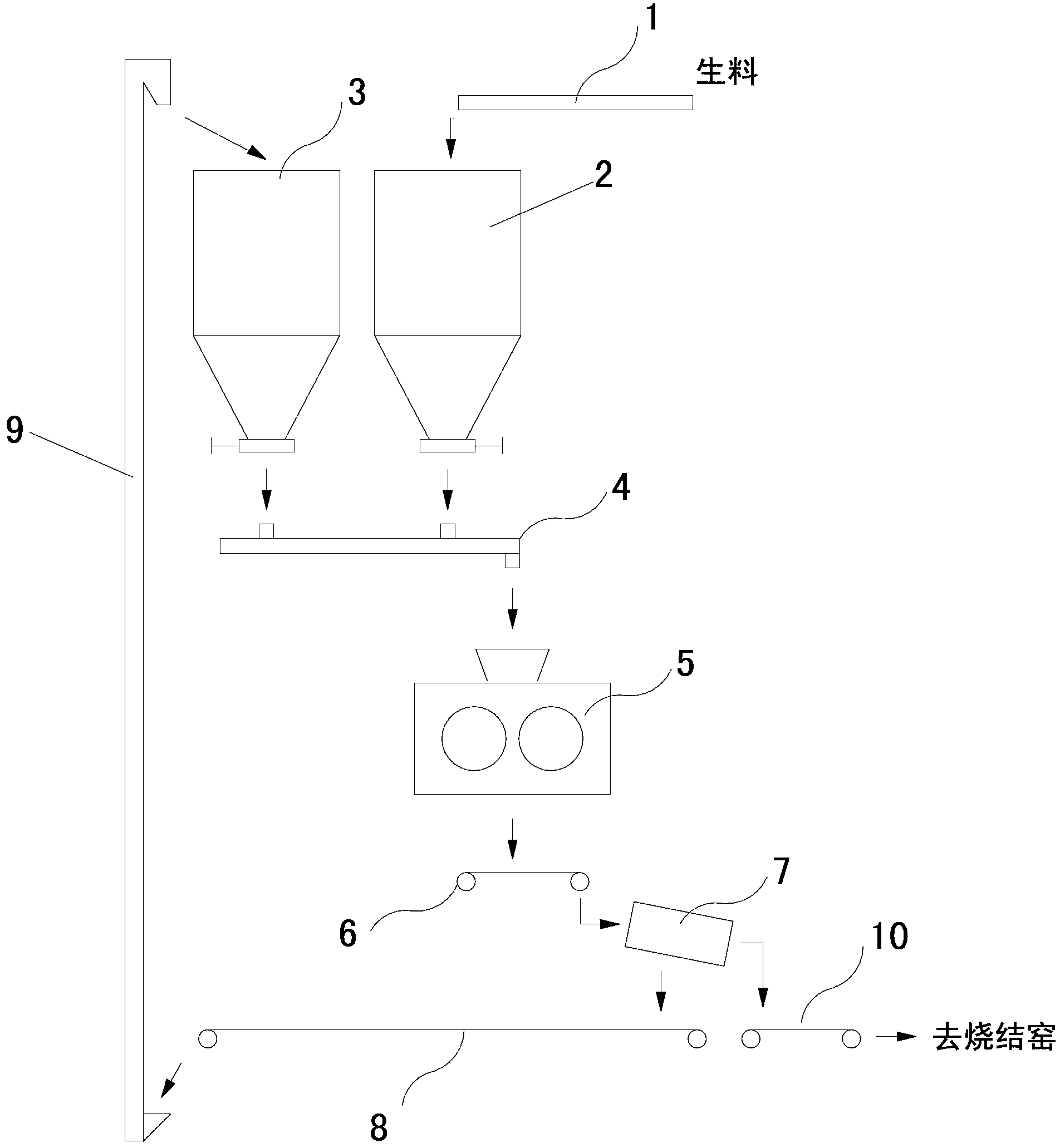

[0019] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, the present invention comprises raw material bin 2, broken ball bin 3, conveyor, ball press 5, sieve 7; the outlet of conveyor one 1 is connected with raw material bin 2, and the outlet of raw material bin 2 is connected with conveyor two 4 is connected; the second conveyor 4 is connected with the ball pressing machine 5, and the discharge port of the ball pressing machine 5 is connected with the third conveyor 6. Conveyor 3 6 is connected to the feed port of sieve 7, the discharge port on sieve 7 is connected to conveyor 4 10, and conveyor 4 10 is connected to the sintering kiln system; the discharge port under sieve 7 is connected to conveyor 5 8; Conveyor five 8 is connected with hoist 9, and hoist 9 is connected with broken ball bin 3; the outlet of broken ball bin 3 is connected with conveyor two 4.

[0020] Each set of pellet preparation device is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com