Numerical control trimming machine tool for machining burrs and flashes of cast curved-surface blank

A rough and sand-flooding technology, applied in the field of CNC trimming machine tools, can solve the problems of high labor intensity, harsh production environment, and more dust, and achieve the effects of improving processing efficiency, reducing production costs, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

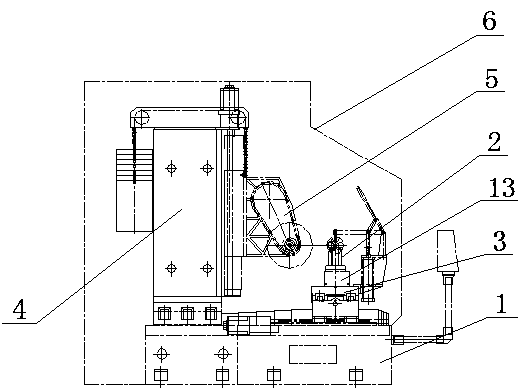

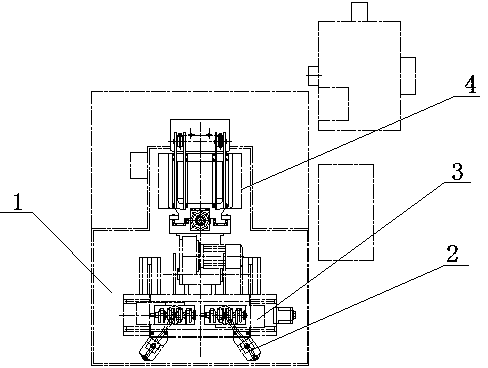

[0021] Such as figure 1 It is a structural schematic diagram of the present invention, a CNC edge trimming machine tool for processing casting curved surface rough sand and flash, including a base 1 and a protective cover 6, and the base 1 is provided with a clamp mechanism 2, a cross table 3, and a column feeder. Give the sliding table 4 and the double-ended grinding head 5.

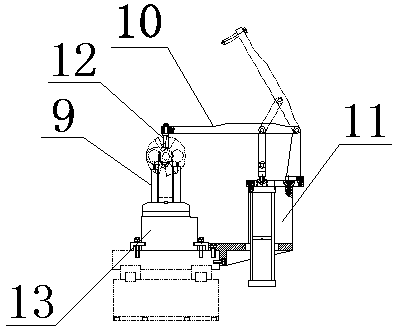

[0022] According to another embodiment of the present invention, it further includes that the clamp mechanism 2 includes a V-shaped positioning bracket 7, an axial centering device 8, a radial limit support 9, a connecting rod type clamping plate 10, a clamping double force The cylinder 11 , and the clamping rod 12 , the V-shaped positioning bracket 7 , the axial centering device 8 , and the radial limit support 9 are installed on the numerically controlled rotary table 13 .

[0023] According to another embodiment of the present invention, it further includes that the double-headed grinding head 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com