Bullet-proof and leakage-proof security upgraded tire as well as manufacturing method thereof

A safety upgrade, tire technology, applied in tire parts, transportation and packaging, vehicle parts, etc., to achieve good durability and dynamic balance performance, significant economic benefits, and improve driving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the following describes the specific implementation, structure, production method, steps, Features and their effects are described in detail below.

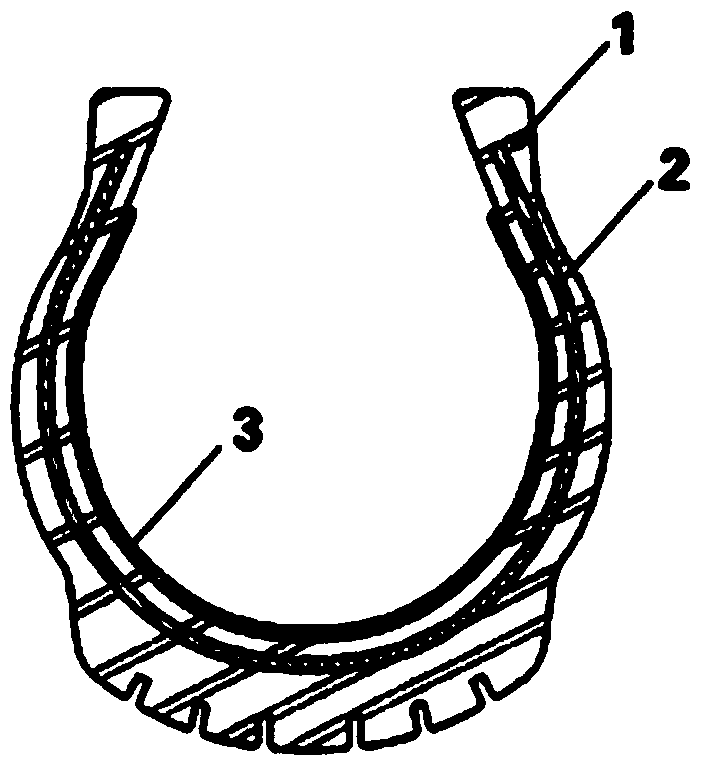

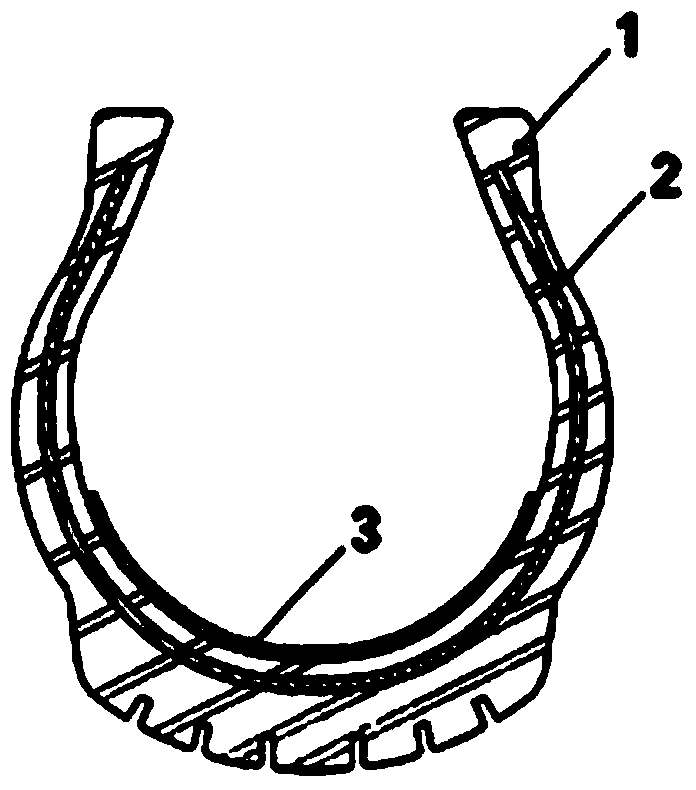

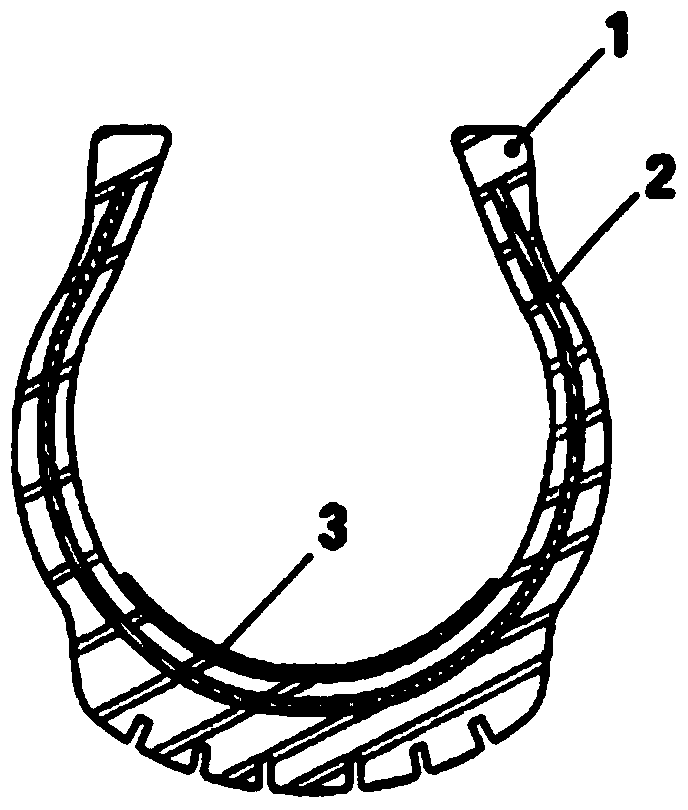

[0029] Bulletproof, leakproof, safety upgrade tires, three types of structures, see details Figure 1a , Figure 1b , Figure 1c . In the three figures, the tire carcass 1, the tire belt layer 2, and the tire self-sealing layer 3 are shown.

[0030] Components and ratio of polymer self-sealing material: 100 parts by mass of styrene thermoplastic elastomer, 100 parts by mass of tackifier, 80 parts by mass of softener, and 50 parts by mass of additives;

[0031] 100 parts by mass of styrene thermoplastic elastomer, 100-150 parts by mass of tackifier, and 85-125 parts by mass of material tackifier auxiliary; see Table 1 for the specific mass ratio.

[0032] Table 1

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com