Automotive sunshade roof with crease-resistant folded fabrics and method for manufacturing same

A folding cloth, anti-wrinkle technology, applied in vehicle parts, movable outer sheath, transportation and packaging, etc., can solve the problem of not easy to be re-rolled into the roller blind, achieve good dustproof and sunshade effect, small size, easy to use Easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

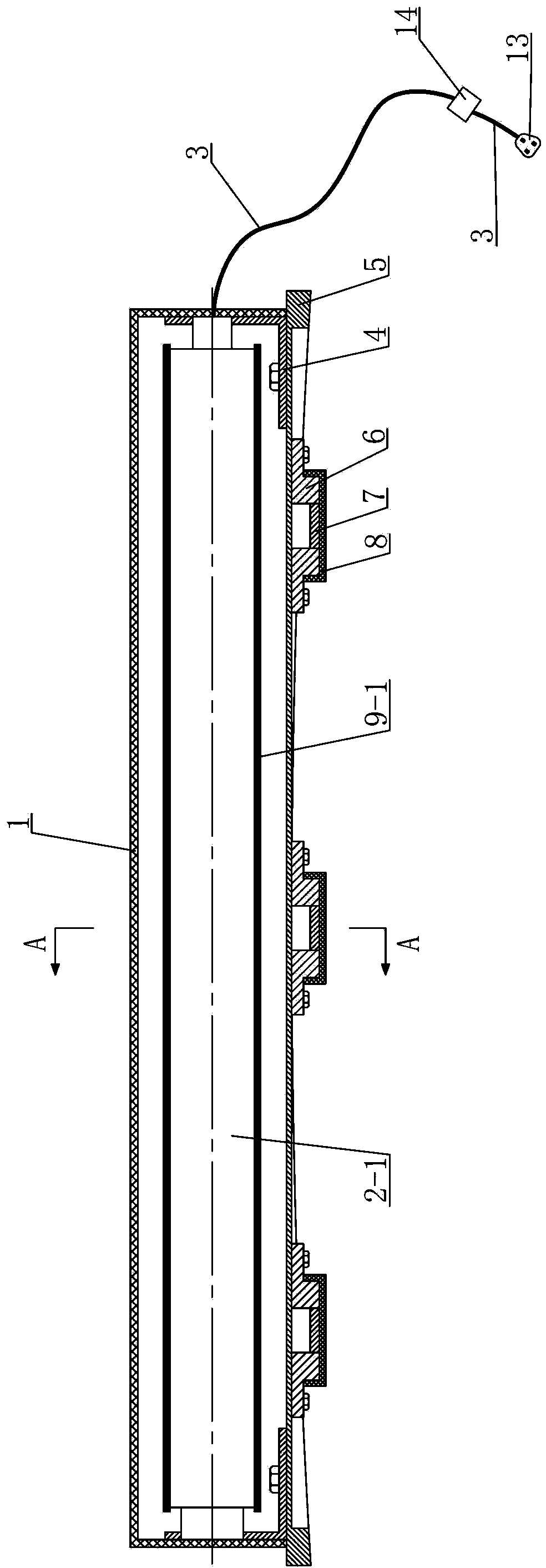

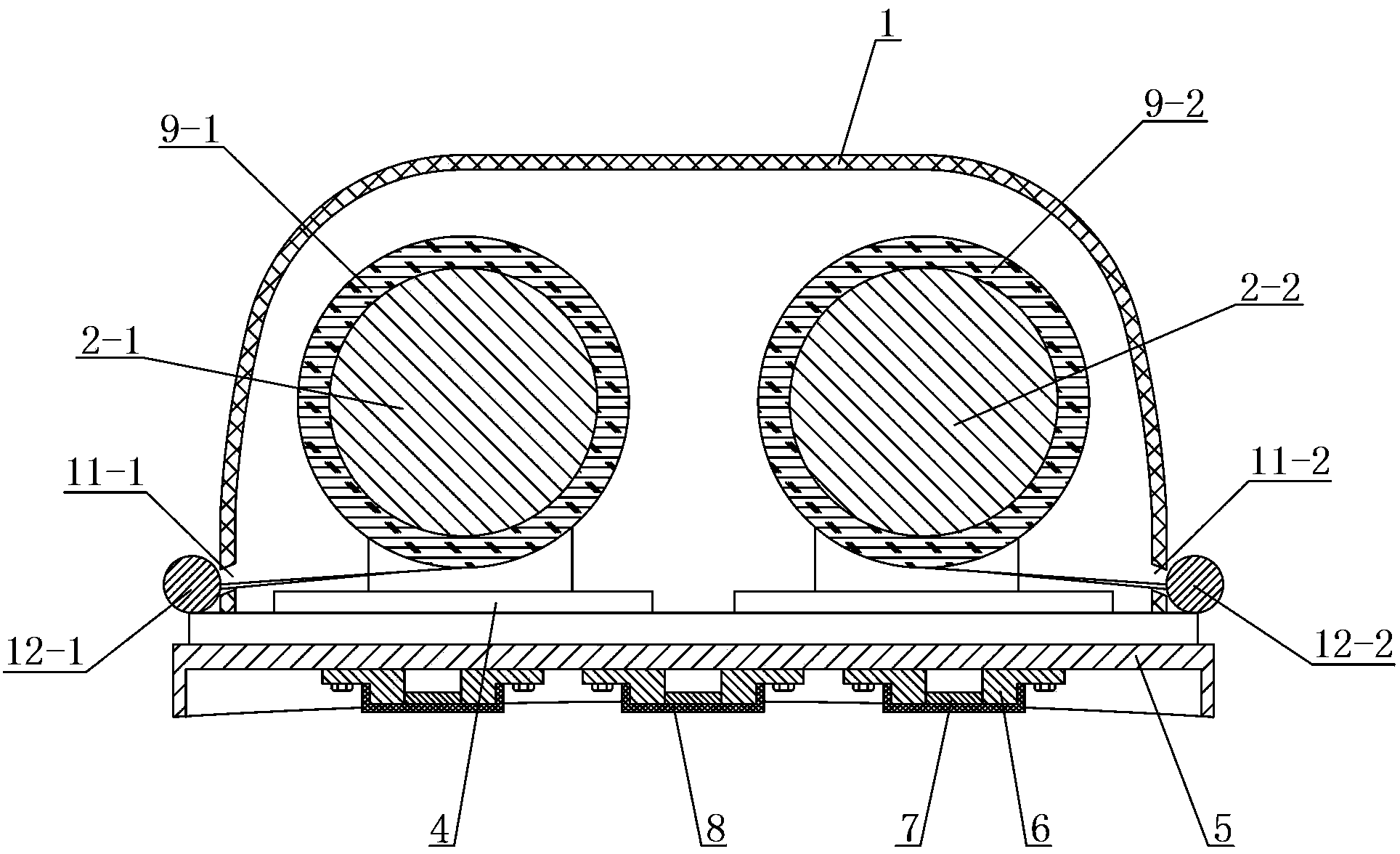

[0046] Such as figure 1 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, a car sunshade roof with anti-wrinkle folding cloth includes an arc-shaped cover 1 and a bottom plate 5 arranged below it. The bottom of the bottom plate 5 is equipped with a permanent magnet 7 and is installed on the car body through the permanent magnet 7. On the top plate, an electric roller blind 1 2-1 for covering the front surface of the car body and an electric roller blind 2 2-2 for covering the rear surface of the car body are installed side by side in the arc-shaped cover 1. The front folding cloth 9-1 is wound on the roller shutter tube of the electric roller blind one 2-1, and the folded cloth 9-2 is wound on the roller shutter tube of the electric roller blind two 2-2. One side of the lower part of the cover 1 is provided with a horizontal groove 11-1 for pulling out and recovering the front folded cloth 9-1, and the other side of the lower part of the arc-shaped co...

Embodiment 2

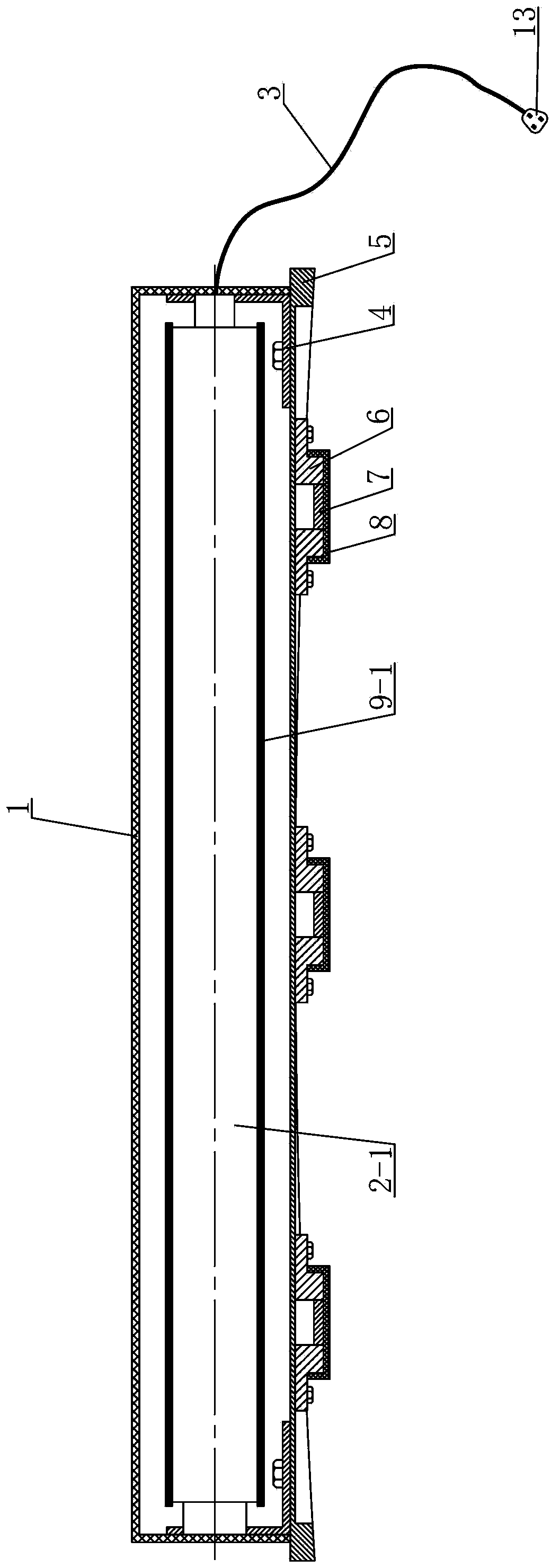

[0061] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the motors of the first electric roller blind 2-1 and the second electric roller blind 2-2 are DC motors, and the DC motors are connected to the plug 13 through the power cord 3. catch. In this embodiment, the structure, connection relationship, working principle of the remaining parts and the manufacturing methods of the front folded cloth 9-1 and the rear folded cloth 9-2 are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com