A kind of method that strengthens manganese oxide to remove the complexing agent of hg (ii) in water

A manganese oxide and water removal technology, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of low Hg(II) removal rate and achieve operational Low cost, high mercury removal efficiency, flexible and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

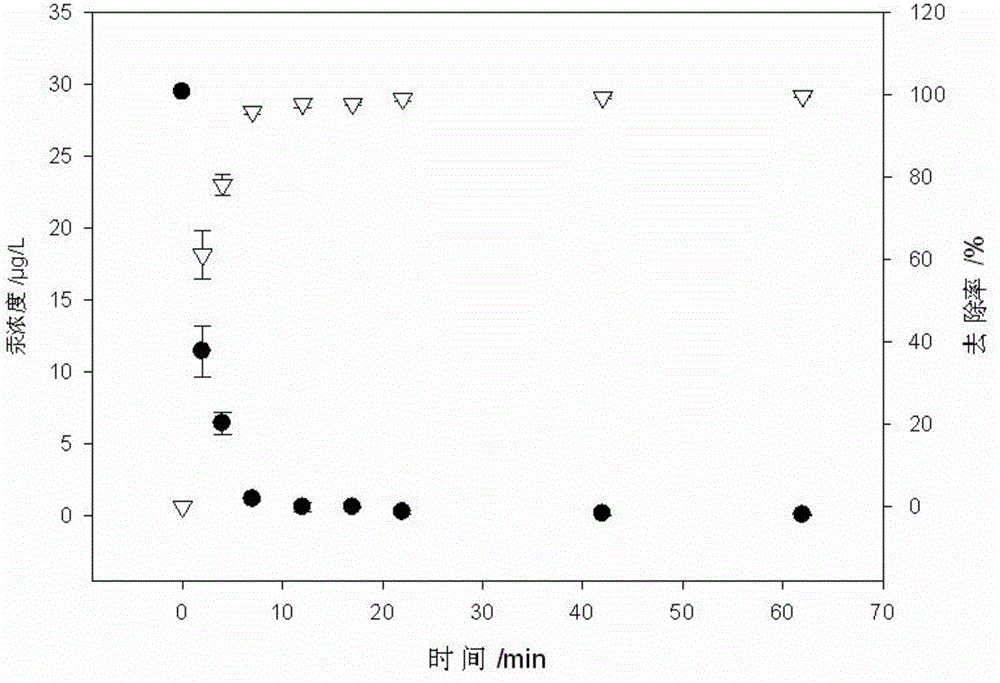

[0013] Specific implementation mode one: a kind of method of strengthening manganese oxide to remove the complexing agent of Hg(II) in water according to the present embodiment is realized according to the following steps: 1. Add complexing agent to water containing Hg(II), and then throw Add an adsorbent, then stir and react at a speed of 100-350r / min for 1-60min to obtain a mixed solution; 2. Add a coagulant to the mixed solution obtained in step 1, and then go through conventional water treatment processes for coagulation, filtration, After precipitation and clarification, the complexing agent for strengthening manganese oxide to remove Hg(II) in water is completed;

[0014] The molar ratio of the complexing agent to Hg in the first step is 2-10000:1; the dosage of the adsorbent is 1-50 mg / L in terms of manganese; the dosage of the coagulant in the second step is 10 mg / L.

specific Embodiment approach 2

[0015] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the complexing agent described in step one is sodium thiosulfate. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0016] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the adsorbent described in step 1 is new ecological iron manganese or nano new ecological manganese. The preparation method of new ecological iron and manganese is the solid matter obtained by permanganate oxidation of ferrous sulfate or ferrous chloride; The resulting solid material. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com