Industrial furnace with modular combined design

A combined design and industrial furnace technology, applied in furnaces, heat treatment furnaces, manufacturing tools, etc., can solve problems such as inability to respond flexibly, rising energy consumption per ton of the production line, and large-scale continuous furnaces, etc., to reduce repeated investment in research and development, reduce Design and manufacture cycle, realize the effect of saving energy and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

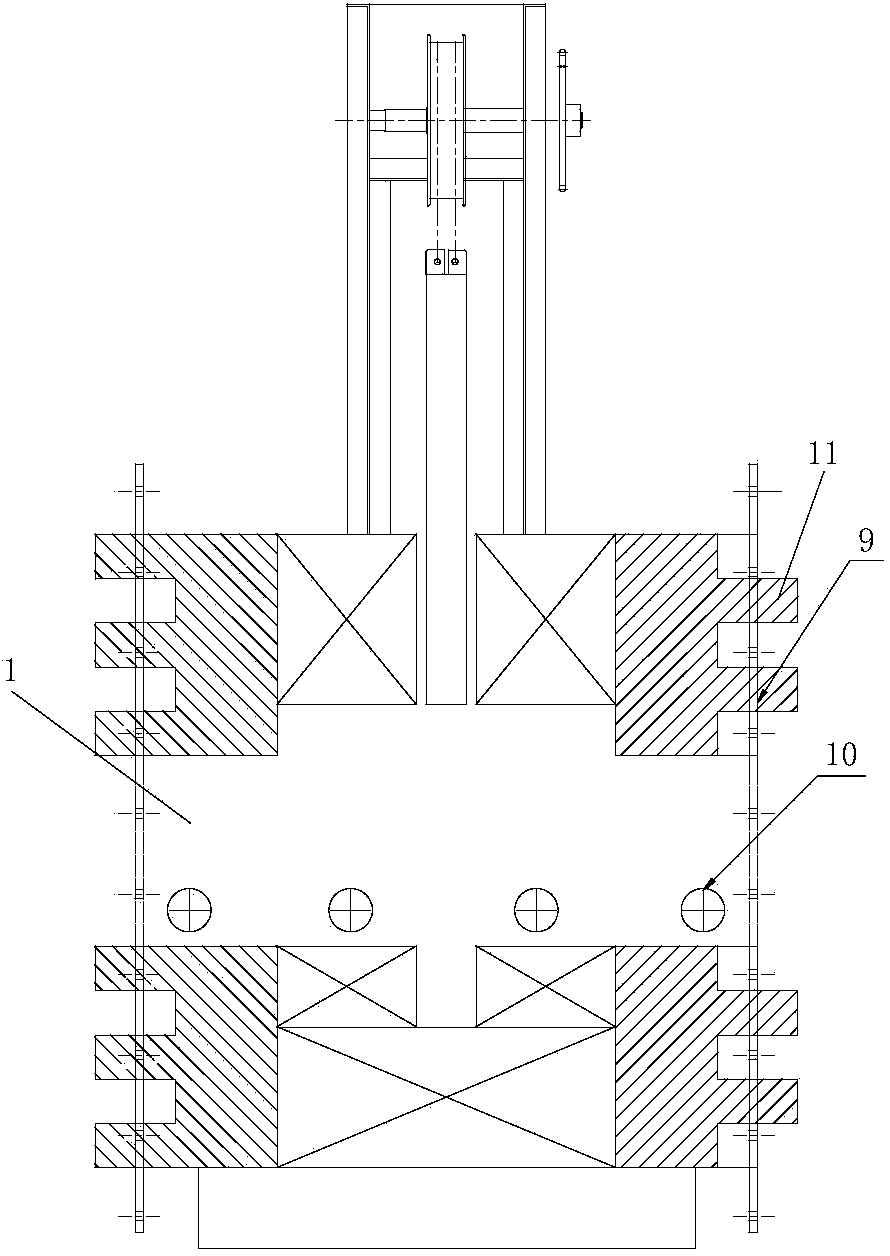

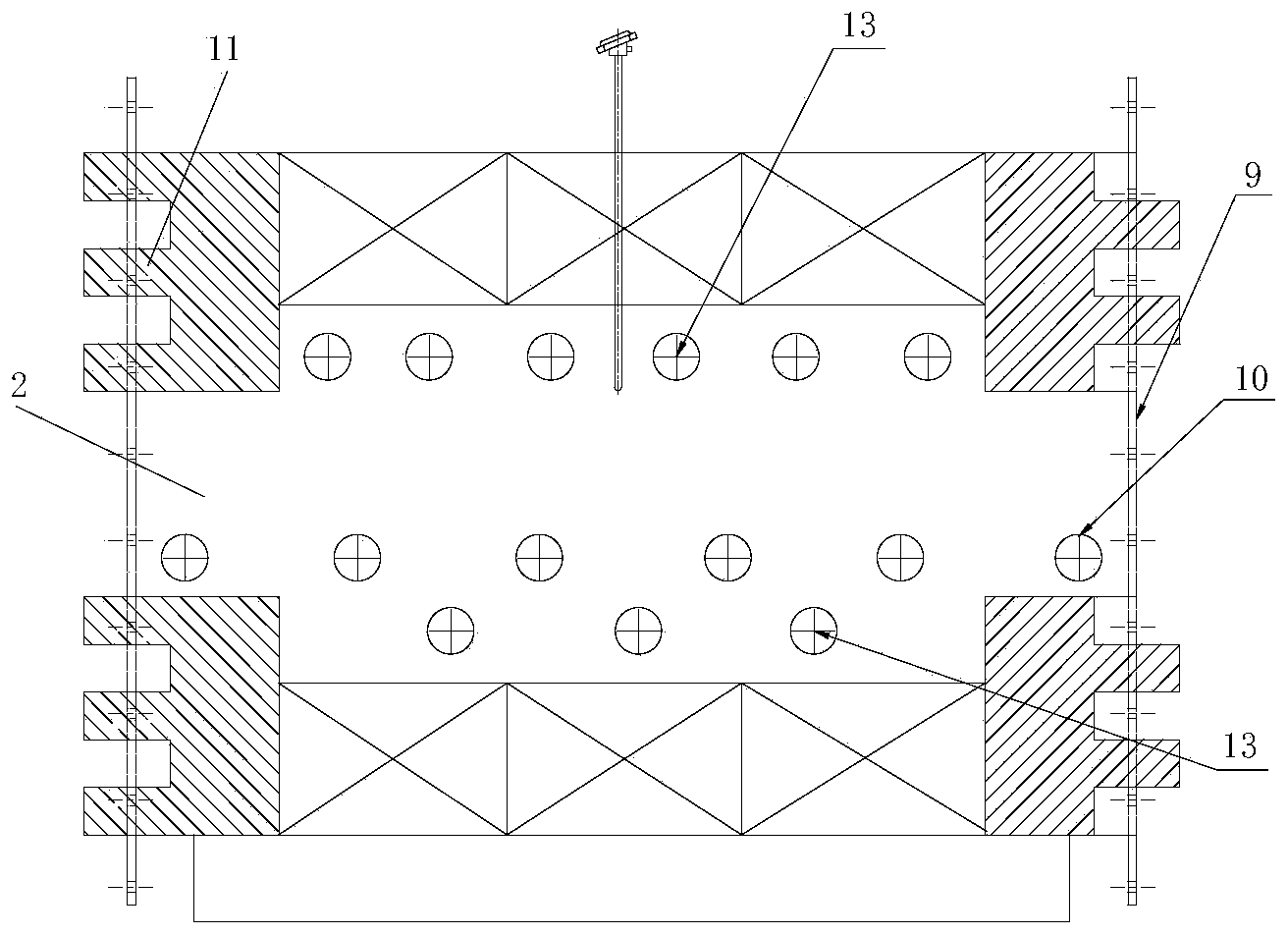

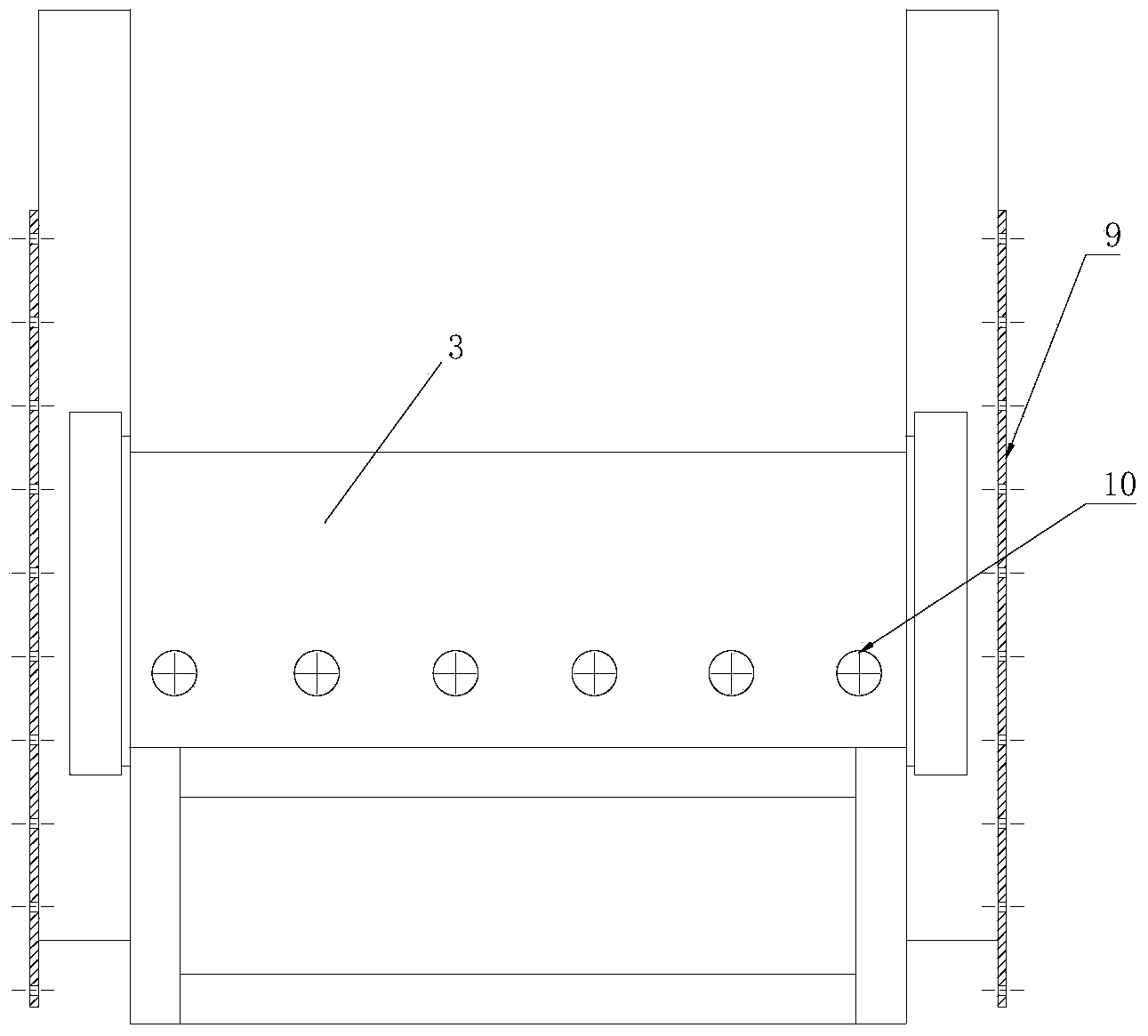

[0024] The present invention will be described in detail below in conjunction with accompanying drawing: Figures 1 to 9 As shown, the present invention includes a furnace door module 1, a furnace body module 2, a vacuum chamber module 3, an air-cooled chamber module 4, a quenching chamber module 5, a water-cooled warehouse module 6, a loading and unloading platform module 7 and a cleaning and drying machine module 8. Sub-modules, the two ends of each sub-module in the industrial furnace are provided with assembly flanges 9, and the sub-modules and sub-modules are connected by the assembly flanges 9 at both ends with bolts 12 and gaskets to form a heat treatment production line, and The heat treatment production line is composed of a sub-module or several sub-modules according to different processes. Through the independent electromechanical system of each chamber and the furnace structure that can be combined and assembled, according to the size of the production capacity, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com