Variable valve lift mechanism

A valve lift and variable technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems that the popularity is not as expected, and achieve no mutual interference, good linear output performance, and good linear control performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

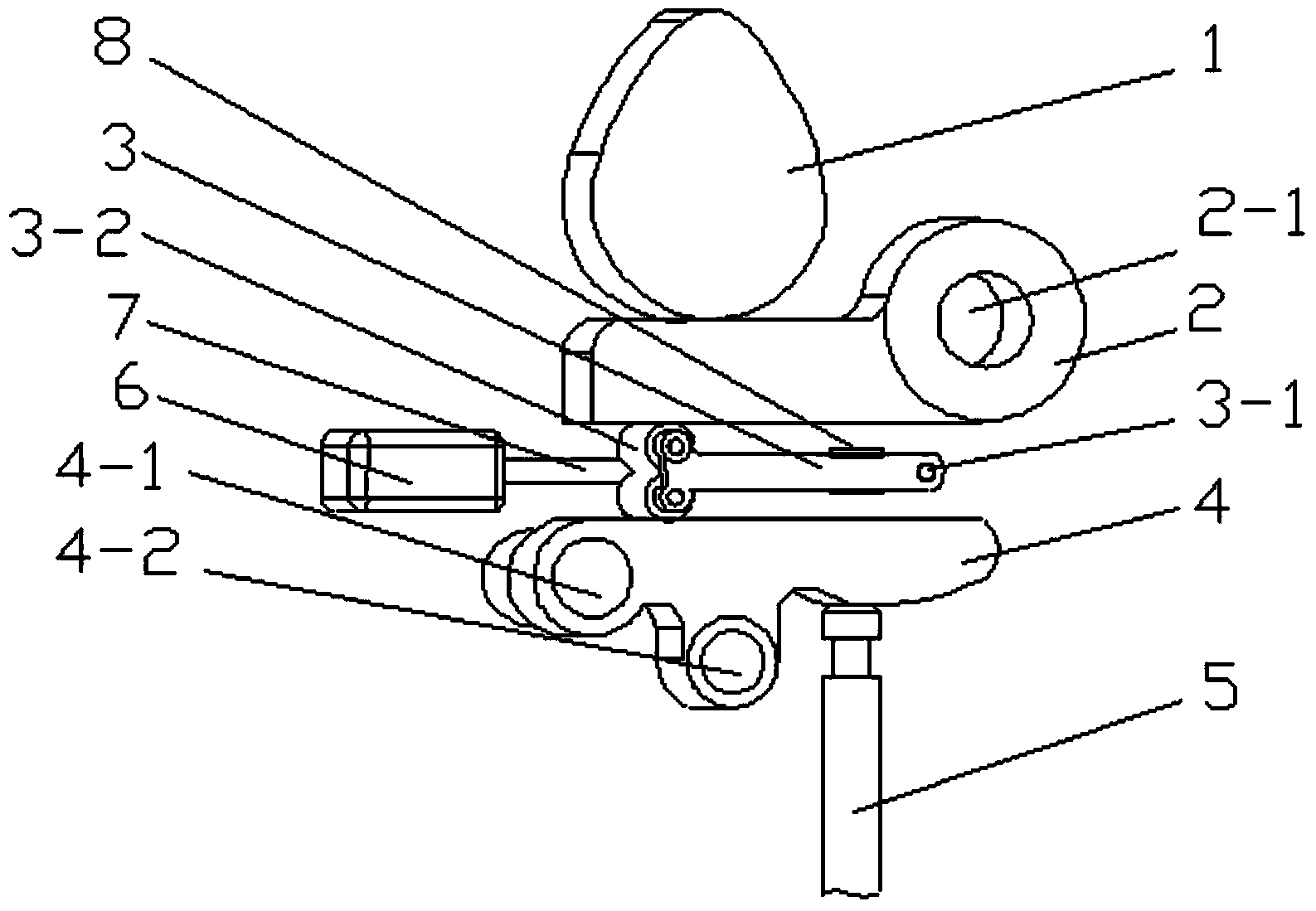

[0026] like figure 1 shown. The variable valve lift mechanism of the present invention includes an upper rocker arm 2, a lower rocker arm 4, and a valve 5. The right end of the upper rocker arm 2 has a round hole 2-1, and the upper surface of the upper rocker arm 2 is provided with a cam 1. , the upper surface and the lower surface of the upper rocker arm 2 are flat, and the lower surface of the cam 1 is in sliding contact with the upper surface of the upper rocker arm 2;

[0027] The left end of the lower rocker arm 4 has a hole for being sleeved on the positioning shaft 4-1 of the engine cylinder head. The upper surface of the lower rocker arm 4 is a plane, and the lower surface of the right end of the lower rocker arm 4 is an arc surface. ;

[0028] An intermediate rocker 3 is arranged between the upper rocker 2 and the lower rocker 4, the right end of the middle rocker 3 is provided with a mounting hole 3-1, and the left end is provided with two vertically symmetrical ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com