Method for improving measuring precision of thermal resistance thermometer

A thermal resistance thermometer and measurement accuracy technology, which is applied in the field of nuclear power plant measurement, can solve problems such as the inability to reduce the deviation of the thermometer, achieve the effects of improving safety and economy, reducing errors, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

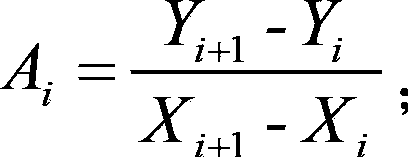

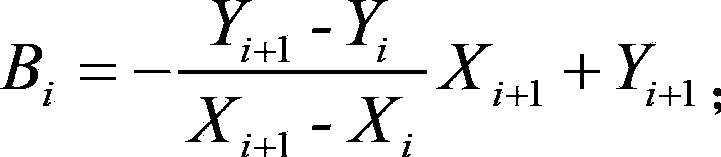

[0021] A method for improving the measurement accuracy of a thermal resistance thermometer of the present invention includes the following steps:

[0022] Step 1. Select m points within the measurement range of a resistance thermometer as temperature calibration reference points, where the output temperature value of the nth reference point is Y n , N=1,2,3,…,m;

[0023] Step 2: Each resistance thermometer is attached with a data sheet when it leaves the factory, and the resistance value R of the nth temperature calibration reference point is collected according to the data sheet of the resistance thermometer. n ;

[0024] Step 3: According to the resistance value R of the nth temperature calibration reference point collected in step 2 n , And then obtain the input temperature value X corresponding to the nth temperature calibration reference point by the following formula n ;

[0025] R n =R 0 (1+AX n +BX n 2 );

[0026] Where R 0 =100Ω, when according to IEC6075 standard, A=3.9083×10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com