Three-way confining pressure and temperature combined loading device for Hopkinson compression bar impact test

A Hopkinson compression bar and combined loading technology, applied in the direction of measuring devices, strength characteristics, instruments, etc., can solve the problem of loading devices lacking Hopkinson compression bar impact experiments, unable to provide material dynamic parameters, and unable to perform material dynamics problems such as scientific experiments to achieve the effect of ensuring axial pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

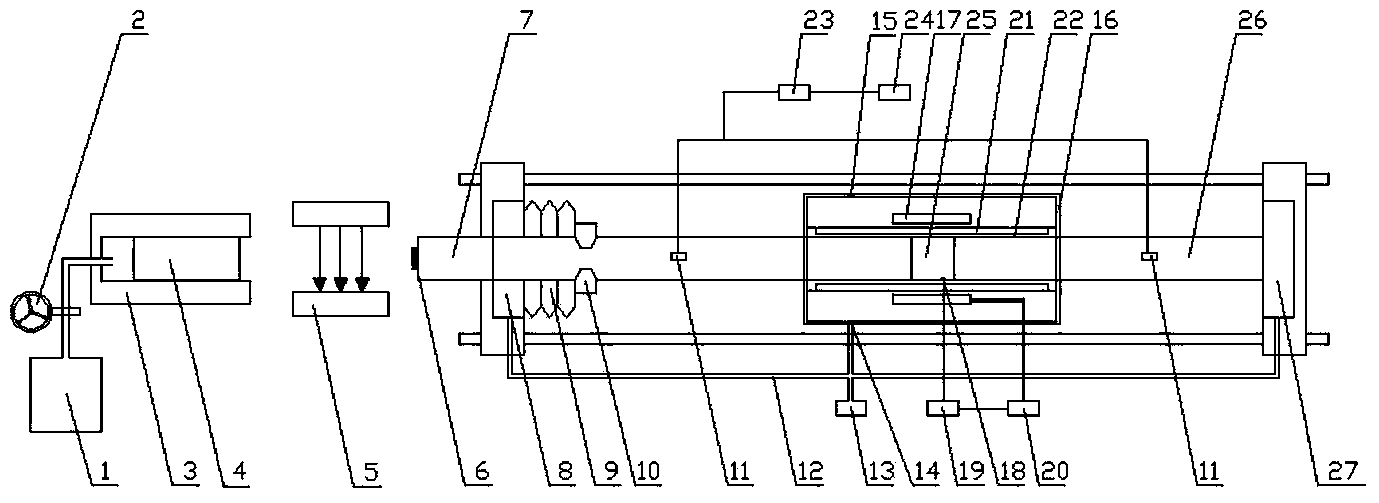

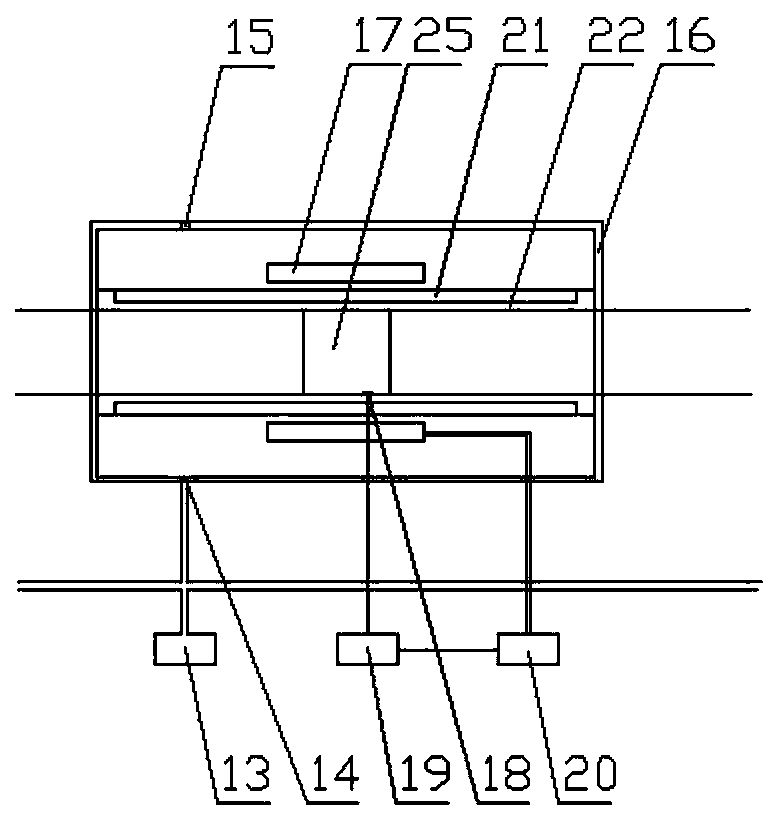

[0014] Such as figure 1 Shown is a Hopkinson compression bar impact test device equipped with a three-way confining pressure and temperature combined loading device for the Hopkinson compression bar impact test of the present invention. The Hopkinson pressure rod impact test device includes bullets 4 , incident rods 7 , test pieces 25 and transmission rods 26 arranged on a fixed bracket in sequence along the axial direction. The bullet 4 is placed in the bullet launching mechanism 3, and the high-pressure gas tank 1 is connected with the bullet launching mechanism 3 to provide power for the bullet launching device 3. A speedometer 5 is arranged between the bullet 4 and the incident rod 7 to measure the incident velocity of the bullet 4 . The portion of the incident rod 7 impacted by the bullet is provided with a wave-shaping gasket 6 . A strain gauge 25 is attached to the incident rod 7 and the transmission rod 26 ; the strain measured by the strain gauge 25 is finally recor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com